Abstract

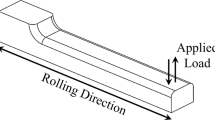

In this study, the low-pressure carbonitriding (LPCN) response of four different steel alloys is investigated. The influence of unprotected boron is evaluated by comparing the microstructure and fatigue performance of 20MnCr5 with and without boron additions after LPCN. Similarly, the influence of Nb microalloying is assessed by comparing 8620 steel with and without Nb additions. Low-pressure carbonitriding heat treatments were developed to achieve case depths of 0.65-0.75 mm in each alloy, thus allowing the influence of alloying and microstructure to be explored independent of case depth. The hardness and case microstructure are correlated with bending fatigue response measured with Brugger fatigue specimens, which are designed to simulate the root of a gear tooth. The 20MnCr5 alloys had the highest fatigue strength, and the 8620 alloys had the lowest fatigue strength, despite having the same hardness profile and case depth. Reductions in prior austenite grain size and increased surface hardness appeared to have a positive effect on the endurance limit of the steel alloys. Retained austenite volume fraction on the surface of the steel alloys as well as non-martensitic transformation products subsurface in the case did not have an apparent direct contribution to fatigue performance.

Similar content being viewed by others

References

T. Marray, P. Jacquet, M. Mansori, A. Fabre, and L. Barrallier, A Thermodynamic and Experimental Study of Low Alloy Steels After Carbonitriding in a Low-Pressure Atmosphere, Met. Sci. Heat Treat., 2014, 56, p 434–439

C. Kanchanomai and W. Limtrakarn, Effect of Residual Stress on Fatigue Failure of Carbonitrided Low-Carbon Steel, J. Mater. Eng. Perform., 2008, 17, p 879–887

J. Dossett, and G.E. Totten, Introduction to surface hardening of steels, in ASM Handbook, vol. 4A (ASM International. Materials Park, 2013), pp. 393–395

T. Hoffmanm M. Steinbacher, B. Clausen, S. Bischoff, H. Klümper-Westkamp, and H. Zoch, New carbonitriding processes, in Proceedings of 26th ASM Heat Treating Society Conference (2011), pp. 115–121

A. Goldsteinas, New vacuum processes achieve mechanical property improvement in gearbox components, Gear Technol., 2007, 24, p 34–39

D.J. Dixon and A.M. Mood, A Method for Obtaining and Analyzing Sensitivity Data, J. Am. Stat. Assoc., 1948, 43(241), p 109–126

J. Spice, D. Matlock, and G. Fett, Optimized Carburized Steel Fatigue Performance as Assessed with Gear and Modified Brugger Fatigue Tests, SAE Technical Publication, no. 2002-01-1003 (SAE, Warrendale, 2002)

I. Yoshimoto, Fatigue Test by Staircase Method with Small Samples, Bull. JSME, 1962, 15(18), p 211–221

C.F. Jatczak, Retained Austenite and Its Measurements by x-Ray Diffraction, SAE Technical Paper 800426 (1980)

W. Crafts and J. Lamont, Effect of some elements on hardenability, Am. Inst. Min. Metall. Eng., 1944, 1657, p 1–11

W. Leslie, Physical Metallurgy of Steels, McGraw-Hill, New York, 1981

G.F. Melloy, P.R. Summon, and P.P. Podgursky, Optimizing the Boron Effect, Metall. Mater. Trans., 1973, 4, p 2279–2289

J. Dossett, and G.E. Totten, Hardenability calculation of carbon and low-alloy steels with low or medium carbon, in ASM Handbook, vol. 4A (ASM International. Materials Park, 2013), pp. 64–71

D.T. Llewellyn and W.T. Cook, Metallurgy of Boron-Treated Low-Alloy Steels, Met. Technol., 1975, 1, p 517–529

P. Yan and H.K.D.H. Bhadeshia, The Austenite-Ferrite Transformation in Enhanced-Niobium, Low-Carbon Steel. Mater. Sci. Technol., 2015, 31(9), p 1066–1076

D.K. Matlock, K.A. Alogab, M.D. Richards, and J.G. Speer, Surface Processing to Improve the Fatigue Resistance of Advanced Bar Steels for Automotive Applications, Mater. Res., 2005, 8, p 453–459

R.E. Thompson, Microstructural Development and Fatigue Behavior of Niobium Modified Carburizing Steels, MS Thesis, Colorado School of Mines, Department of Metallurgical and Materials Engineering (2007)

C.M. Enloe, K.O. Findley, J.G. Speer, A. Shibata, D. Terada, and N. Tsuji, The effects of Mo and initial precipitate distribution on (Nb,Ti)(C,N) precipitate size evolution in a high-temperature carburizing steel, in Proceedings of the 3rd International Symposium on Steel Science (ISSS-2012) (ISIJ, Tokyo, 2012) pp. 163–166

M.M.A. Bepari, Carburizing: A Method of Case Hardening of Steel, Mater. Sci. Mater. Eng., 2017, 2, p 71–106

ASTM Standard Practice, Standard Practice for x-Ray Determination of Retained Austenite in Steel with Neat random Crystallographic Orientation, ASTM E975-13 (2013)

J.M. Prado and J.L. Arques, Influence of Retained Austenite on the Fatigue Endurance of Carbonitrided Steels, J. Mater. Sci., 1984, 19, p 2980–2988

R. Tricot, M. Lacoude, and B. Champin, Étude Analytique des Processus Governant le Comportement en Service des Engrenages, Revue de Métallurgie, 1972, 69(7–8), p 497–514

J. Wyszkowski, H. Priegnitz, E. Gozdzik, and A. Ratkiewicz, Influence de L’austénite Rédiduelle sur Qualques Propriétés de L’acier Cémenté, Revue de Métallurgie, 1971, 68(6), p 411–422

J. Schmuck, Comparison of Surface Properties of Carburized and Carbonitrided Parts, Aciers Speciaux, 1976, 33, p 5–15

K.O. Findley, G. Krauss, R.J. Johnson, and D.K. Matlock, Deterministic Analysis of Crack Growth Rates in Carburized Steels, Procedia Eng., 2011, 10, p 370–375

R.S. Hyde, G. Krauss, and D.K. Matlock, The Effect of Reheat Treatments on Fatigue and Fracture of Carburized Steels, J. Mater. Manuf., 1994, 103(section 5), p 588–596

J.P. Wise, G. Krauss, and D.K. Matlock, Microstructure and fatigue resistance of carburized steels, in 20th ASM Heat Treating Society Conference Proceeding (ASM International, St. Louis, 2000), pp. 152–161

Acknowledgments

The authors gratefully acknowledge the support of the Brazilian CNPq—Science without Boarders program and the sponsors of the Advanced Steel Processing and Products Research Center (ASPPRC) and CBMM North America. Additionally, the authors gratefully acknowledge the support of the National Science Foundation CAREER Award No. 0955236.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vilela Costa, L., Corrêa de Oliveira, D., Wallace, D. et al. Bending Fatigue in Low-Pressure Carbonitriding of Steel Alloys with Boron and Niobium Additions. J. of Materi Eng and Perform 29, 3593–3602 (2020). https://doi.org/10.1007/s11665-020-04757-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04757-2