Abstract

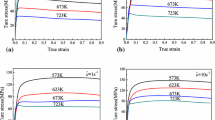

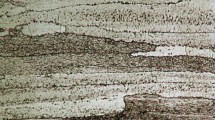

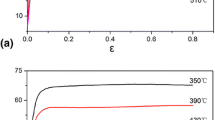

The hot compressive tests of 6082 aluminum alloy were conducted on a Gleeble-3500 thermomechanical simulator at temperature ranges of 380-530 °C and strain rate range of 0.01-10 s−1. The constitutive analysis and microstructural evolution of the alloy were investigated. It was indicated that the peak stress increased with increasing strain rate and decreasing temperature. Dynamic recovery and dynamic recrystallization lead to the softening behavior of the alloy. In order to characterize the flow behavior of this alloy, some models were established based on the experimental data including the phenomenological Arrhenius-type model, the physically based Estrin and Mecking (EM) model for work hardening and dynamic recovery, and the EM model, which was combined with the Avrami equation for dynamic recrystallization. An artificial neural network model was also established to predict the flow stress. The results indicate that the Arrhenius-type model is more simple and more efficient than the EM + Avrami model. Moreover, the well-trained ANN model has the best predicting performance.

Similar content being viewed by others

References

J. Hirsch, Aluminium Alloys for Automotive Application, Mater. Sci. Forum, 1997, 242, p 33–50

J.H. Chen, E. Costan, M. Huis, Q. Xu, and H.W. Zandbergen, Atomic Pillar-Based Nanoprecipitates Strengthen AlMgSi Alloys, Science, 2006, 312, p 416–419

L.P. Troeger and E.A. Starke Jr., Microstructural and Mechanical Characterization of a Superplastic 6xxx Aluminum Alloy, Mater. Sci. Eng., A, 2000, 277, p 102–113

B. Mirzakhani and Y. Payandeh, Combination of Sever Plastic Deformation and Precipitation Hardening Processes Affecting the Mechanical Properties in Al-Mg-Si Alloy, Mater. Des., 2015, 68, p 127–133

C.N. Panagopoulos, E.P. Georgiou, and A.G. Gavras, Corrosion and Wear of 6082 Aluminum Alloy, Tribol. Int., 2009, 42, p 886–889

A.R. Eivani and J. Zhou, Application of Physical and Numerical Simulations for Interpretation of Peripheral Coarse Grain Structure During Hot Extrusion of AA7020 Aluminum Alloy, J. Alloys Compd., 2017, 725, p 41–53

N. Kumar, S. Goel, R. Jayaganthan, and G.M. Owolabi, The Influence of Metallurgical Factors on Low Cycle Fatigue Behavior of Ultra-Fine Grained 6082 Al Alloy, Int. J. Fatigue, 2018, 110, p 130–143

V. Kumar and D. Kumar, Investigation of Tensile Behaviour of Cryorolled and Room Temperature Rolled 6082 Al Alloy, Mater. Sci. Eng., A, 2017, 691, p 211–217

X. Kai, C. Chen, X. Sun, C. Wang, and Y. Zhao, Hot Deformation Behavior and Optimization of Processing Parameters of a Typical High-Strength Al-Mg-Si Alloy, Mater. Sci., 2016, 90, p 1151–1158

G. Chunlei, X. Yongdong, and W. Mengjun, Prediction of the Flow Stress of Al6061 at Hot Deformation Conditions, Mater. Sci. Eng., A, 2011, 528, p 4199–4203

L. De Pari Jr. and W.Z. Misiolek, Theoretical Predictions and Experimental Verification of Surface Grain Structure Evolution for AA6061 During Hot Rolling, Acta Mater., 2008, 56, p 6174–6185

M.R. Rokni, A. Zarei-Hanzaki, A.A. Roostaei, and H.R. Abedi, An Investigation into the Hot Deformation Characteristics of 7075 Aluminum Alloy, Mater. Des., 2011, 32, p 2339–2344

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

D. Trimble and G.E.O. Donnell, Constitutive Modelling for Elevated Temperature Flow Behaviour of AA7075, Mater. Des., 2015, 76, p 150–168

L. Wang, F. Liu, Q. Zuo, and C.F. Chen, Prediction of Flow Stress for N08028 Alloy Under Hot Working Conditions, Mater. Sci., 2013, 47, p 737–745

H. Zhang, G. Chen, Q. Chen, F. Han, and Z. Zhao, A Physically-Based Constitutive Modelling of a High Strength Aluminum Alloy at Hot Working Conditions, J. Alloys Compd., 2018, 743, p 283–293

R. Bobbili, B. VenkataRamudu, and V. Madhu, A Physically-Based Constitutive Model for Hot Deformation of Ti-10-2-3 Alloy, J. Alloys Compd., 2017, 696, p 295–303

B. Li, Q. Pan, and Z. Yin, Microstructural Evolution and Constitutive Relationship of Al-Zn-Mg Alloy Containing Small Amount of Sc and Zr During Hot Deformation Based on Arrhenius-Type and Artificial Neural Network Models, J. Alloys Compd., 2014, 584, p 406–416

H.R.R. Ashtiani and P. Shahsavari, A Comparative Study on the Phenomenological and Artificial Neural Network Models to Predict Hot Deformation Behavior of AlCuMgPb Alloy, J. Alloys Compd., 2016, 687, p 263–273

D. Odoh, Y. Mahmoodkhani, and M. Wells, Effect of Alloy Composition on Hot Deformation Behavior of Some Al-Mg-Si Alloys, Vacuum, 2018, 149, p 248–255

M.E. Mehtedi, S. Spigarelli, F. Gabrielli, and L. Donati, Comparison Study of Constitutive Models in Predicting the Hot Deformation Behavior of AA6060 and AA6063 Aluminium Alloys, Mater. Today Proc., 2015, 2, p 4732–4739

K. Singh, S.K. Rajput, and Y. Mehta, Modeling of the Hot Deformation Behavior of a High Phosphorus Steel Using Artificial Neural Networks, Mater. Discov., 2016, 6, p 1–8

M.C. Dixit, N. Srivastava, and S.K. Rajput, Modeling of Flow Stress of AA6061 Under Hot Compression Using Artificial Neural Network, Mater. Today Proc., 2017, 4, p 1964–1971

B.K. Raghunath, K. Raghukandan, R. Karthikeyan, K. Palanikumar, U.T.S. Pillai, and R.A. Gandhi, Flow Stress Modeling of AZ91 Magnesium Alloys at Elevated Temperature, J. Alloys Compd., 2011, 509, p 4992–4998

H. Sun, Y. Zhang, A.A. Volinsky, B. Wang, B. Tian, K. Song, Z. Chai, and Y. Liu, Effects of Ag Addition on Hot Deformation Behavior of Cu-Ni-Si Alloys, Adv. Eng. Mater., 2017, 19, p 1600607

E.S. Puchi-Cabrera, M.H. Staia, J.D. Guérin, J. Lesage, M. Dubar, and D. Chicot, An Experimental Analysis and Modeling of the Work-Softening Transient Due to Dynamic Recrystallization, Int. J. Plast, 2014, 54, p 113–131

N. Dudova, A. Belyakov, T. Sakai, and R. Kaibyshev, Dynamic Recrystallization Mechanisms Operating in a Ni-20%Cr Alloy Under Hot-to-Warm Working, Acta Mater., 2010, 58, p 3624–3632

T. Zhong, K.P. Rao, Y.V.R.K. Prasad, F. Zhao, and M. Gupta, Hot Deformation Mechanisms, Microstructure and Texture Evolution in Extruded AZ31-Nano-alumina Composite, Mater. Sci. Eng., A, 2014, 589, p 41–49

D. Samantaray, S. Mandal, C. Phaniraj, and A.K. Bhaduri, Flow Behavior and Microstructural Evolution During Hot Deformation of AISI, Type 316 L(N) Austenitic Stainless Steel, Mater. Sci. Eng., A, 2011, 528, p 8565–8572

Y. Han, G. Liu, D. Zou, R. Liu, and G. Qiao, Deformation Behavior and Microstructural Evolution of As-Cast 904L Austenitic Stainless Steel During Hot Compression, Mater. Sci. Eng., A, 2013, 565, p 342–350

Y. Deng, Z. Yin, and J. Huang, Hot Deformation Behavior and Microstructural Evolution of Homogenized 7050 Aluminum Alloy During Compression at Elevated Temperature, Mater. Sci. Eng. A, 2011, 528, p 1780–1786

D. Xiao, X. Peng, X. Liang, Y. Deng, G. Xu, and Z. Yin, Research on Constitutive Models and Hot Workability of As-Homogenized Al-Zn-Mg-Cu Alloy During Isothermal Compression, Met. Mater. Int., 2017, 23, p 591–602

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322, p 43–63.

S. Spigarelli, E. Evangelista, and H.J. McQueen, Study of Hot Workability of a Heat Treated AA6082 Aluminum Alloy, Scripta Mater., 2003, 49, p 179–183.

Z. Cai, F. Chen, and J. Guo, Constitutive Model for Elevated Temperature Flow Stress of AZ41M Magnesium Alloy Considering the Compensation of Strain, J. Alloys Compd., 2015, 648, p 215–222.

P. Changizian, A. Zarei-Hanzaki, and A.A. Roostaei, The High Temperature Flow Behavior Modeling of AZ81 Magnesium Alloy Considering Strain Effects, Mater. Des., 2012, 39, p 384–389.

J.J. Jonas, X. Quelennec, L. Jiang, and É. Martin, The Avrami Kinetics of Dynamic Recrystallization, Acta Mater., 2009, 57, p 2748–2756

U.F. Kocks, Laws for Working-Hardening and Low-Temperature Creep, J. Eng. Mater. Technol., 1976, 98, p 76–85

H.M.Y. Estrin, A Unified Phenomenological Description of Work Hardening and Creep Based on One-Parameter Models, Acta Metall., 1984, 32, p 57–70

P.M. Souza, H. Beladi, R. Singh, B. Rolfe, and P.D. Hodgson, Constitutive Analysis of Hot Deformation Behavior of a Ti6Al4V Alloy Using Physical Based Model, Mater. Sci. Eng. A, 2015, 648, p 265–273

N. Haghdadi, D. Martin, and P. Hodgson, Physically-Based Constitutive Modelling of Hot Deformation Behavior in a LDX 2101 Duplex Stainless Steel, Mater. Des., 2016, 106, p 420–427

Y. Han, G. Qiao, J. Sun, and D. Zou, A Comparative Study on Constitutive Relationship of As-Cast 904L Austenitic Stainless Steel During Hot Deformation Based on Arrhenius-Type and Artificial Neural Network Models, Comput. Mater. Sci., 2013, 67, p 93–103

Acknowledgments

The authors would like to acknowledge the financial support of the Science and Technology Major Project of Hunan Province (2016GK1004) and the Science and Technology Key Project of Guangdong Province (2016B090931001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, K., Pan, Q., Li, R. et al. Constitutive Modeling of the Hot Deformation Behavior in 6082 Aluminum Alloy. J. of Materi Eng and Perform 28, 981–994 (2019). https://doi.org/10.1007/s11665-019-3873-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-3873-5