Abstract

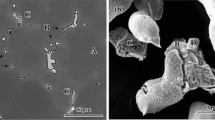

Grain boundaries (GBs) in nickel-based superalloys have a significant influence on the creep resistance of these alloys. In this study, the trace elements of boron and zirconium were added to the newly designed LESS 1 (Ni-22Cr-20Co-2W-2Nb-1.5Al-1.5Ti-0.03C) alloy, and their effects on the GB precipitation behaviors of carbides were observed. The combined addition of boron and zirconium generates a continuous film structure containing MC carbides and M23(C, B)6-type boro-carbides, as well as a grain boundary γ′. Based on the change in microstructure, rupture time is significantly increased. According to the observed microstructures and simulation results, it was confirmed that boron forms M23(C, B)6-type boro-carbides and zirconium appears to stabilize MC carbides at GBs.

Similar content being viewed by others

References

R.C. Reed, The Superalloys Fundamentals and Applications, Cambridge University Press, New York, 2006, p 53–54

L.Z. He, Q. Zheng, X.F. Sun, H.R. Guan, Z.Q. Hu, A.K. Tieu, C. Lu, and H.T. Zhu, Effect of carbides on the creep properties of a Ni-base superalloy M963, Mater. Sci. Eng. A, 2005, 397, p 297–304

Y.H. Rong, Y.X. Guo, and G.X. Hu, Characterization of M23C6 carbide precipitated at grain boundaries in a superalloy, Mater. Charact., 1989, 22, p 47–55

A. Baldan, Effects of grain size and carbides on the creep resistance and rupture properties of a conventionally cast nickel-base superalloy, Z. Metallkunde, 1992, 83(10), p 750–757

R.F. Decker and J.W. Freeman, The mechanism of beneficial effects of boron and zirconium on creep-rupture properties of a complex heat-resistant alloy, Trans. Metall. Soc. AIME, 1960, 218, p 277–285

K.G. Carroll, L.S. Darken, E.W. Filer, and L. Zwell, A new iron boro-carbide, Nature, 1954, 174, p 978–979

M.A. Bruke, J. Greggi, Jr., and G.A. Whitlow, The effect of boron and carbon on the microstructural chemistries of two wrought nickel base superalloy, Scr. Mater., 1984, 18, p 91–94

W. Chen, M.C. Chaturvedi, N.L. Richards, and G. Mcmahon, Grain boundary segregation of boron in INCONEL 718, Metall. Trans. A, 1998, 29A, p 1947–1954

M. Thuvander and K. Stiller, Microstructure of a boron containing high purity nickel-based alloy 690, Mater. Sci. Eng. A, 2000, 281, p 96–103

Y. Murata, K. Suga, and N. Yukawa, Effect of transition elements on the properties of MC carbides in IN-100 nickel-based superalloy, J. Mater. Sci., 1986, 21, p 3653–3660

Y.L. Tsai, S.F. Wang, H.Y. Bor, and Y.F. Hsu, Effects of Zr addition on the microstructure and mechanical behavior of a fine-grained nickel-based superalloy at elevated temperatures, Mater. Sci. Eng. A, 2014, 607, p 294–301

J. I. Youn, Y. K. Shin, B. I. Kang, Y. J. Kim, J. I. Suk, S. H. Ryu, Study on phase stability of new ni based superalloy LEES 1 designed to low the eta and sigma phase fraction at 700 °C. in Proceedings of the Energy materials 2014, November 4–6, 2014, (Xi’an, China), CSM & TMS, (2015), p 145–150

M.L. Saucedo-Munoz, S. Komazaki, T. Takahashi, T. Hashida, and T. Shoji, Creep property measurement of service-exposed SUS 316 austenitic stainless steel by the small-punch creep-testing technique, J. Mater. Res., 2002, 17(8), p 1945–1953

K. Milička and F. Dobeš, Small punch testing of P91 steel, Int. J. Press. Vessels Pip., 2006, 83, p 625–634

C.T. Sims and W.C. Hagel, The superalloys, Wiley, New York, 1972, p 64–69

G. D. Smith, S. J. Patel, The role of niobium in wrought precipitation-hardened nickel-base alloys. in Proceedings of the Sixth International Symposium on superalloys 718, 625, 706 and derivatives, ed. by E.A. Loria, October 2–5, 2005 (Pittsburgh, USA), TMS, (2005), p 135–154

C. Wang, Y. Guo, J. Guo, and L. Zhou, Microstructural stability and mechanical properties of a boron modified Ni-Fe based superalloy for steam boiler applications, Mater. Sci. Eng. A, 2015, 639, p 380–388

P. Kontis, H.A. Mohd Yusof, S. Pedrazzini, M. Danaie, K.L. Moore, P.A.J. Bagot, M.P. Moody, C.R.M. Grovernor, and R.C. Reed, On the effect of boron on grain boundary character in a new polycrystalline superalloy, Acta Mater., 2016, 103, p 688–699

ASM handbook Volume 03: Phase diagram, ASM International, OH (1992)

Acknowledgments

This work was supported by the Technology Innovation Program (10052860, Development of Superalloys and Manufacturing Technologies for the Rotor/Casing of the 700 °C grade HSC Steam Turbine), which is funded by the Ministry of Trade, industry, and Energy (MI, Korea).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kang, BI., Han, CH., Shin, YK. et al. Effects of Boron and Zirconium on Grain Boundary Morphology and Creep Resistance in Nickel-Based Superalloy. J. of Materi Eng and Perform 28, 7025–7035 (2019). https://doi.org/10.1007/s11665-019-04419-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04419-y