Abstract

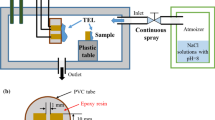

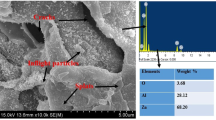

The effect of sulfide concentration on the corrosion and cavitation erosion behavior of a cast manganese-aluminum bronze (MAB) alloy in 3.5% NaCl solution was investigated. The electrochemical results showed that when the sulfide concentration exceeded 50 ppm, hydrogen evolution reaction dominated the cathodic process because of the very negative corrosion potential of MAB, and the formation of a copper sulfide film on MAB was a diffusion-controlled process. The mass loss rate of MAB after longer-term immersion was ordered by the sulfide concentration as: 20/50 ppm > 100 ppm > zero > 200 ppm. In the 200 ppm sulfide solution, the mass loss rate of MAB was the lowest, because of the formation of a thin and homogeneous copper sulfide film. In the other sulfide solutions, the formation of a less-protective film with both oxides and sulfides resulted in higher mass loss rate of MAB. Moreover, selective phase corrosion occurred at the β and κ phases in solutions with sulfide addition less than 100 ppm. For all solutions, it was the mechanical attack that dominated cavitation erosion degradation. The cavitation erosion–corrosion synergy was lower in high sulfide solutions, because the corrosion products on MAB could reduce the mechanical impact under cavitation erosion.

Similar content being viewed by others

References

J.S. Carlton, Marine Propellers and Propulsion, Butterworths/Heinemann, Oxford, 1994

C.H. Tang, F.T. Cheng, and H.C. Man, Effect of Laser Surface Melting on the Corrosion and Cavitation Erosion Behaviors of a Manganese-Nickel-Aluminium Bronze, Mater. Sci. Eng. A, 2004, 373, p 195–203

A.H. Tuthill, Guidelines for the Use of Copper Alloys in Seawater, Mater. Perform., 1987, 26, p 12–22

A.L. Ma, S.L. Jiang, Y.G. Zheng, and W. Ke, Corrosion Product Film Formed on the 90/10 Copper–Nickel Tube in Natural Seawater: Composition/Structure and Formation Mechanism, Corros. Sci., 2015, 91, p 245–261

J.A. Wharton, R.C. Barik, G. Kear, R.J.K. Wood, K.R. Stokes, and F.C. Walsh, The Corrosion of Nickel-Aluminium Bronze in Seawater, Corros. Sci., 2005, 47, p 3336–3367

B.G. Ateya, E.A. Ashour, and S.M. Sayed, Corrosion of α-Al Bronze in Saline Water, J. Electrochem. Soc., 1994, 141, p 71–78

J.M. Popplewell, R.J. Hart, and J.A. Ford, The Effect of Iron on the Corrosion Characteristics of 90–10 Cupro Nickel in Quiescent 34% NaCl Solution, Corros. Sci., 1973, 13, p 295–309

S. Neodo, D. Carugo, J.A. Wharton, and K.R. Stokes, Electrochemical Behaviour of Nickel-Aluminium Bronze in Chloride Media: Influence of pH and Benzotriazole, J. Electroanal. Chem., 2013, 695, p 38–46

M.R.R. Jamal and N. Alhajji, On the Effects of Common Pollutants on the Corrosion of Copper-Nickel Alloys in Sulfide Polluted Seawater, J. Electrochem. Soc., 1995, 142, p 2944–2953

K. Rahmouni, M. Keddam, A. Srhiri, and H. Takenouti, Corrosion of Copper in 3% NaCl Solution Polluted by Sulphide Ions, Corros. Sci., 2005, 47, p 3249–3266

S.J. Yuan and S.O. Pehkonen, Surface Characterization and Corrosion Behavior of 70/30 Cu–Ni Alloy in Pristine and Sulfide-Containing Simulated Seawater, Corros. Sci., 2007, 49, p 1276–1304

N.K. Awad, E.A. Ashour, A.S. Fouda, and N.K. Allam, Effect of Alloying Elements on the Electrochemical Behavior of Cu–Ni–Zn Ternary System in Sulfide-Polluted Saltwater, Appl. Surf. Sci., 2014, 307, p 621–630

E.A. Ashour, L.A. Khorshed, G.I. Youssef, H.M. Zakria, and T.A. Khalifa, Electrochemical and Stress Corrosion Cracking Behavior of Alpha-Al Bronze in Sulfide-Polluted Salt Water: Effect of Environmentally-Friendly Additives, Mater. Sci. Appl., 2014, 5, p 10–19

N.K. Awad, E.A. Ashour, and N.K. Allam, Unravelling the Composition of the Surface Layers Formed on Cu, Cu-Ni, Cu-Zn and Cu-Ni-Zn in Clean and Polluted Environments, Appl. Surf. Sci., 2015, 346, p 158–164

S.M. Sayed, E.A. Ashour, G.I. Youssef, and S.M. El-Raghy, Effect of Sulfide Ions on the Stress Corrosion Behaviour of Al-Brass and Cu10Ni Alloys in Salt Water, J. Mater. Sci., 2002, 37, p 2267–2272

M. Hazra and K.P. Balan, Failure of a Nickel Aluminium Bronze (NAB) Canned Motor Pump Impeller Working Under Polluted Sea Water—Influence of Material Selection, Section Thickness Dependent Microstructure and Temper Annealing Heat Treatment, Eng. Fail. Anal., 2016, 70, p 141–156

S.M. Sayed, E.A. Ashour, and G.I. Youssef, Effect of Sulfide Ions on the Corrosion Behaviour of Al-Brass and Cu10Ni Alloys in Salt Water, Mater. Chem. Phys., 2003, 78, p 825–834

N. Taniguchi and M. Kawasaki, Influence of Sulfide Concentration on the Corrosion Behavior of Pure Copper in Synthetic Seawater, J. Nucl. Mater., 2008, 379, p 154–161

D. Kong, C. Dong, A. Xu, C. Man, C. He, and X. Li, Effect of Sulfide Concentration on Copper Corrosion in Anoxic Chloride-Containing Solutions, J. Mater. Eng. Perform., 2017, 26, p 1741–1750

R.J.K. Wood, Marine Wear and Tribocorrosion, Wear, 2017, 376–377, p 893–910

A. Karimi and J.L. Martin, Cavitation Erosion of Materials, Inter. Met. Rev., 1986, 31, p 1–26

A. Alhashem, P.G. Caceres, W.T. Riad, and H.M. Shalaby, Cavitation Corrosion Behavior of Cast Nickel-Aluminum Bronze in Seawater, Corrosion, 1995, 51, p 331–342

Q.N. Song, Y.G. Zheng, S.L. Jiang, D.R. Ni, and Z.Y. Ma, Comparison of Corrosion and Cavitation Erosion Behaviors Between the As-Cast and Friction-Stir-Processed Nickel Aluminum Bronze, Corrosion, 2013, 69, p 1111–1121

Y. Qiao, J. Chen, H. Zhou, Y. Wang, Q. Song, H. Li, and Z. Zheng, Effect of Solution Treatment on Cavitation Erosion Behavior of High-Nitrogen Austenitic Stainless Steel, Wear, 2019, 424–425, p 70–77

J. Ryl, J. Wysocka, P. Slepski, and K. Darowicki, Instantaneous Impedance Monitoring of Synergistic Effect Between Cavitation Erosion and Corrosion Processes, Electrochim. Acta, 2016, 203, p 388–395

Q.N. Song, N. Xu, Y.F. Bao, Y.F. Jiang, W. Gu, Y.G. Zheng, and Y.X. Qiao, Corrosion and Cavitation Erosion Behaviors of Two Marine Propeller Materials in Clean and Sulfide-Polluted 3.5% NaCl Solutions, Acta Metall. Sin. Engl. Lett., 2017, 30, p 712–720

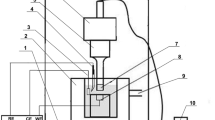

ASTM International G32-03, Standard Test for Cavitation Erosion Using Vibratory Apparatus. West Conshohocken: ASTM International (2003).

J. Iqbal, F. Hasan, and F. Ahmad, Characterization of Phases in an As-Cast Copper-Manganese-Aluminum Alloy, J. Mater. Sci. Technol., 2006, 22, p 779–784

P. Punburi, N. Tareelap, N. Srisukhumbowornchai, C. Euaruksakul, and V. Yordsri, Correlation Between Electron Work Functions of Multiphase Cu-8Mn-8Al and De-alloying Corrosion, Appl. Surf. Sci., 2018, 439, p 1040–1046

J.A. Wharton and K.R. Stokes, The Influence of Nickel-Aluminium Bronze Microstructure and Crevice Solution on the Initiation of Crevice Corrosion, Electrochim. Acta, 2008, 53, p 2463–2473

G. Kear, B.D. Barker, and F.C. Walsh, Electrochemical Corrosion of Unalloyed Copper in Chloride Media—A Critical Review, Corros. Sci., 2004, 46, p 109–135

J. Chen and D.W. Shoesmith, Kinetics of Corrosion Film Growth on Copper in Neutral Chloride Solutions Containing Small Concentrations of Sulfide, J. Electrochem. Soc., 2010, 157, p C338–C345

D.C. Kong, C.F. Dong, X.Q. Ni, A.N. Xu, C. He, K. Xiao, and X.G. Li, Long-term Polarisation and Immersion for Copper Corrosion in High-Level Nuclear Waste Environment, Mater. Corros., 2017, 68, p 1070–1079

J. Chen, Z. Qin, L. Wu, J.J. Noël, and D.W. Shoesmith, The Influence of Sulphide Transport on the Growth and Properties of Copper Sulphide Films on Copper, Corros. Sci., 2014, 87, p 233–238

J. Chen, Z. Qin, and D.W. Shoesmith, Long-term Corrosion of Copper in a Dilute Anaerobic Sulfide Solution, Electrochim. Acta, 2011, 56, p 7854–7861

T. Kosec, Z. Qin, J. Chen, A. Legat, and D.W. Shoesmith, Copper Corrosion in Bentonite/Saline Groundwater Solution: Effects of Solution and Bentonite Chemistry, Corros. Sci., 2015, 90, p 248–258

T. Martino, R. Partovi-Nia, J. Chen, Z. Qin, and D.W. Shoesmith, Mechanisms of Film Growth on Copper in Aqueous Solutions Containing Sulphide and Chloride Under Voltammetric Conditions, Electrochim. Acta, 2014, 127, p 439–447

B.C. Syrett, The Mechanism of Accelerated Corrosion of Copper-Nickel Alloys in Sulphide-Polluted Seawater, Corros. Sci., 1981, 21, p 187–209

P. Punburi, N. Tareelap, N. Srisukhumbowornchai, and V. Yordsri, De-alloying Corrosion in the Heat-Affected Zone in Mn-Al Bronze Weld, Mater. Chem. Phys., 2018, 212, p 471–478

Y.G. Zheng, S.Z. Luo, and W. Ke, Cavitation Erosion–Corrosion Behaviour of CrMnB Stainless Overlay and 0Cr13Ni5Mo Stainless Steel in 0.5M NaCl and 0.5M HCl Solutions, Tribol. Int., 2008, 41, p 1181–1189

Y. Qiao, Z. Tian, X. Cai, J. Chen, Y. Wang, Q. Song, and H. Li, Cavitation Erosion Behaviors of a Nickel-Free High-Nitrogen Stainless Steel, Tribol. Lett., 2019, 67, p 1–9. https://doi.org/10.1007/s11249-018-1118-7

Y.G. Zheng, S.Z. Luo, and W. Ke, Effect of Passivity on Electrochemical Corrosion Behavior of Alloys During Cavitation in Aqueous Solutions, Wear, 2007, 262, p 1308–1314

R.J.K. Wood, Erosion–Corrosion Interactions and Their Effect on Marine and Offshore Materials, Wear, 2006, 261, p 1012–1023

C.T. Kwok, F.T. Cheng, and H.C. Man, Synergistic Effect of Cavitation Erosion and Corrosion of Various Engineering Alloys in 3.5% NaCl Solution, Mater. Sci. Eng. A, 2000, 290, p 145–154

R.C. Barik, J.A. Wharton, R.J.K. Wood, and K.R. Stokes, Electro-mechanical Interactions During Erosion–Corrosion, Wear, 2009, 267, p 1900–1908

H. Yu, Y.G. Zheng, and Z.M. Yao, Cavitation Erosion Corrosion Behaviour of Manganese-Nickel-Aluminum Bronze in Comparison with Manganese-Brass, J. Mater. Sci. Technol., 2009, 25, p 758–766

C.H. Tang, F.T. Cheng, and H.C. Man, Laser Surface Alloying of a Marine Propeller Bronze Using Aluminium Powder Part I: Microstructural Analysis and Cavitation Erosion Study, Surf. Coat. Technol., 2006, 200, p 2602–2609

K.R. Trethewey, T.J. Haley, and C.C. Clark, Effect of Ultrasonically Induced Cavitation on Corrosion Behaviour of a Copper-Manganese-Aluminium Alloy, Brit. Corros. J., 1988, 23, p 55–60

Acknowledgments

This research was financially supported by National Natural Science Foundation of China (No. 51601058), Fundamental Research Funds for the Central Universities of People’s Republic of China (No. 2018B59614), Changzhou Sci & Tech Program (No. CJ20180045) and National Natural Science Foundation of China (No. 51879089).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, Q.N., Xu, N., Jiang, X. et al. Effect of Sulfide Concentration on the Corrosion and Cavitation Erosion Behavior of a Manganese-Aluminum Bronze in 3.5% NaCl Solution. J. of Materi Eng and Perform 28, 4053–4064 (2019). https://doi.org/10.1007/s11665-019-04150-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04150-8