Abstract

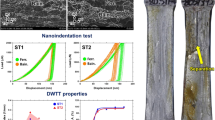

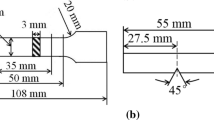

Effect of dual-phase heat treatment (DPHT) on microstructure and mechanical properties of S135 high-strength drill pipe steel was studied by means of optical microscope, scanning electron microscope and mechanical property testing. The results show that the ferrite–martensite dual-phase microstructures were obtained at 760-800 °C. With increase in DPHT temperature, the volume fraction of martensite increases and the ferrite decreases. When the DPHT temperature is low, martensite is distributed as an island on the ferrite matrix, and ferrite is distributed as an island on the martensite matrix when the DPHT temperature is high. The hardness and strength of the steel increase, the plasticity and toughness decrease, the steel changes from ductile fracture to brittle fracture and the micro-fracture morphology changes from dimple to cleavage with increase in DPHT temperature. The strain hardening exponent of the as-received steel shows one ‘n’ value, but exhibits two ‘n’ values after DPHT. When the DPHT temperature is 750 °C, the relative content of martensite in the duplex structure is 15-20%, and the impact energy of the steel is similar to that of the as-received S135 drill pipe steel, and the strength is increased by about 15%. Micropores and micro-cracks on the subsurface of tensile fracture surface are mainly formed at the martensite/ferrite phase boundary or in the martensite slit.

Similar content being viewed by others

References

P. Haslberger, S. Holly, W. Ernst, and R. Schnitzer, Microstructure and Mechanical Properties of High-Strength Steel Welding Consumables with a Minimum Yield Strength of 1100 MPa, J. Mater. Sci., 2018, 53, p 6968–6979

M. Liu, X.Q. Cheng, X.G. Li, Z. Jin, and H.X. Liu, Corrosion Behavior of Cr Modified HRB400 Steel Rebar in Simulated Concrete Pore Solution, Constr. Build. Mater., 2015, 93, p 884–890

J. Wang, S. Gao, Y. Wei, and F. Pan, Influence of Y on the Phase Composition and Mechanical Properties of As-Extruded Mg-Zn-Y-Zr Magnesium Alloys, J. Mater. Sci., 2012, 47, p 2005–2010

D.Z. Li, Y.C. Liu, T.X. Cui, J.M. Li, Y.T. Wang, and P.M. Fu, The Effect of Thermo-mechanical Processing Parameters on Microstructure and Mechanical Properties of a Low Carbon, High Strength Steel, Steel Res. Int., 2013, 85, p 307–313

R.K. Singla, S.N. Maiti, and A.K. Ghosh, Mechanical, Morphological, and Solid-State Viscoelastic Responses of Poly(Lactic Acid)/Ethylene-Co-Vinyl-Acetate Super-Tough Blend Reinforced with Halloysite Nanotubes, J. Mater. Sci., 2016, 51, p 10278–10292

P.R. Mondi and S. Sankaran, Development of Ultra-Fine Grained Dual-Phase Microalloyed Steels Through Severe Cold Rolling and Intercritical Annealing, Trans. Indian Inst. Met., 2011, 64, p 89–92

M. Papa, V.S. Sarma, and S. Sankaran, Development of High Strength and Ductile Ultra Fine Grained Dual-Phase Steel with Nano Sized Carbide Precipitates in a V-Nb Microalloyed Steel, Mat. Sci. Eng. A Struct., 2013, 568, p 171–175

A. Karmakar, R.D.K. Misra, S. Neogy, and D. Chakrabarti, Development of Ultra-Fine Grained Dual-Phase Steels: Mechanism of Grain Refinement During Inter-Critical Deformation, Mater. Sci. Forum, 2014, 2014, p 4106–4118

X. Xu, S.V.D. Zwaag, and W. Xu, The Effect of Martensite Volume Fraction on the Scratch and Abrasion Resistance of a Ferrite–Martensite Dual-Phase Steel, Wear, 2016, 348, p 80–88

M. Liu, S.J. Luo, Y. Shen, and X.Z. Lin, Corrosion Fatigue Crack Propagation Behavior of S135 High-Strength Drill Pipe Steel in H2S Environment, Eng. Fail. Anal., 2019, 97, p 493–505

E. Fereiduni and S.S.G. Banadkouki, Ferrite Hardening Response in a Low Alloy Ferrite–Martensite Dual-Phase Steel, J. Alloy. Compd., 2014, 589, p 288–294

S.M. Zamani, S.A. Hassanzadeh-Tabrizi, and H. Sharifi, Failure Analysis of Drill Pipe: A Review, Eng. Fail. Anal., 2016, 59, p 605–623

S. Luo and S. Wu, Effect of Stress Distribution on the Tool Joint Failure of Internal and External Upset Drill Pipes, Mater. Des., 2013, 52, p 308–314

Q.C. Fu, Numerical Simulation of Pressure Loss in Largesize Annulus of Deepwater Drilling Riser, Mater. Sci. Forum, 2016, 857, p 590–597

A.R. Shahani and S.M.H. Sharifi, Contact Stress Analysis and Calculation of Stress Concentration Factors at the Tool Joint of a Drill Pipe, Mater. Des., 2009, 30, p 3615–3621

S. Roy, G. Kannan, S. Suwas, and M.K. Surappa, Effect of Extrusion Ratio on the Microstructure, Texture and Mechanical Properties of (Mg/AZ91)m-SiCp, Composite, Mat. Sci. Eng. A Struct., 2015, 624, p 279–290

G.W. Yang, X.J. Sun, Z.D. Li, X.X. Li, and Y.Q. Long, Effects of Tempering Temperature on Microstructure and Mechanical Properties of 1500 MPa Grade Nb-Ti Low Alloyed Directly Quenched Steel, Mater. Sci. Technol., 2013, 21, p 118–124

Y. Liu, M. Wang, and G. Liu, Effects of Tempering on Microstructure and Mechanical Properties of 40CrNi3MoV Steel, Heat. Treat. Metals, 2014, 39, p 41–45

H. Ashrafi, S. Sadeghzade, R. Emadi, and M. Shamanian, Influence of Heat Treatment Schedule on the Tensile Properties and Wear Behavior of Dual-Phase Steels, Steel Res. Int., 2017, 88, p 1–11

E.A. Ariza, A. Nishikawa, H. Goldenstein, and A.P. Tschiptschin, Characterization and Methodology for Calculating the Mechanical Properties of a TRIP-Steel Submitted to Hot Stamping and Quenching and Partitioning (Q&P), Mat. Sci. Eng. A Struct., 2016, 671, p 54–69

R.M. Wu, J.W. Li, W. Li, X.C. Wu, X.J. Jin, S. Zhou, and L. Wang, Effect of Metastable Austenite on Fracture Resistance of Quenched and Partitioned (Q&P) Sheet Steels, Mat. Sci. Eng. A Struct., 2016, 657, p 57–63

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe, Orientation Gradients and Geometrically Necessary Dislocations in Ultrafine Grained Dual-Phase Steels Studied by 2D and 3D EBSD, Mat. Sci. Eng. A Struct., 2010, 52, p 2738–2746

J. Kadkhodapour, S. Schmauder, D. Raabe, S. Ziaei-Rad, U. Weber, and M. Calcagnotto, Experimental and Numerical Study on Geometrically Necessary Dislocations and Non-homogeneous Mechanical Properties of the Ferrite Phase in Dual Phase Steels, Acta Mater., 2011, 59, p 4387–4394

L.H. Han, X.Y. Jiang, Y.R. Feng, H.P. Cai, and Q.L. Wang, Effect of Marquenching and Tempering Heat Treatment on Mechanical Behaviors of Drill Pipe Steel, Trans. Mater. Heat. Treat., 2011, 4, p 97–103

S.J. Luo, K. Zhao, and W. Rong, Fatigue Cracks Propagation Behavior of S135 Drill Pipe Steel at Different Stress Ratios, Mater. Mech. Eng., 2013, 37, p 72–76

P. Movaheda, S. Kolahgara, S.P.H. Marashia, M. Pouranvari, and N. Parvin, The Effect of Intercritical Heat Treatment Temperature on the Tensile Properties and Work Hardening Behavior of Ferrite–Martensite Dual-Phase Steel Sheets, Mater. Sci. Eng. A Struct., 2009, 518, p 1–6

H.S. Lee, B.B. Hwang, S. Lee, C.G. Lee, and S.J. Lee, Effects of Martensite Morphology and Tempering on Dynamic Deformation Behavior of Dual-Phase Steels, Metal. Mater. Trans. A, 2004, 35, p 2371–2382

T.W.J.D. Geus, R.H.J. Peerlings, and M.G.D. Geers, Competing Damage Mechanisms in a Two-Phase Microstructure: How Microstructure and Loading Conditions Determine the Onset of Fracture, Int. J. Solids Struct., 2016, 97, p 687–698

K. Hu, J. An, and Y.J. Yoon, Two-Wavelength, Photo-Initiation and Photo-Inhibition Competing for Selective Photo-Patterning of Hydrogel Porous Microstructures, Int. J. Precis. Eng. Manuf., 2018, 19, p 729–735

E. Ahmad, M.M.A. Ziai, and N. Hussain, Effect of Martensite Morphology on Tensile Deformation of Dual-Phase Steel, J. Mater. Eng. Perform., 2012, 21, p 382–387

M. Erdogan and S. Tekeli, The Effect of Martensite Volume Fraction and Particle Size on the Tensile Properties of a Surface-Carburized AISI, 8620 Steel with a Dual-Phase Core Microstructure, Mater. Charact., 2002, 49, p 445–454

S.A. Etesami, M.H. Enayati, A. Taherizadeh, and B. Sadeghian, The Influence of Volume Fraction of Martensite and Ferrite Grain Size on Ultimate Tensile Strength and Maximum Uniform True Strain of Dual-Phase Steel, Indian Inst. Metals, 2016, 69, p 1605–1612

A. Bayram and A. Uğuz, Effect of Microstructure on the Wear Behaviour of a Dual-Phase Steel, Mater. Werkst., 2015, 32, p 249–252

Y.I. Son, Y.K. Lee, K.T. Park, C.S. Lee, and D.H. Shin, Ultrafine Grained Ferrite–Martensite Dual-Phase Steels Fabricated via Equal Channel Angular Pressing: Microstructure and Tensile Properties, Acta Mater., 2005, 53, p 3125–3134

K. Hamad, R.B. Megantoro, and Y.G. Ko, Microstructure and Texture Evolution in Low Carbon Steel Deformed by Differential Speed Rolling (DSR) Method, J. Mater. Sci., 2014, 49, p 6608–6619

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51801149), China Postdoctoral Science Foundation (No. 2017M620448) and Fund of State Key Laboratory for Strength and Vibration of Mechanical Structures (No. SV2019-KF-10).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, S., Liu, M. Effect of Dual-Phase Heat Treatment on Microstructure and Mechanical Properties of S135 High-Strength Drill Pipe Steel. J. of Materi Eng and Perform 28, 3063–3075 (2019). https://doi.org/10.1007/s11665-019-04075-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04075-2