Abstract

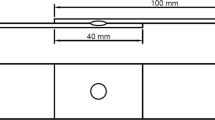

Advanced high-strength steels used in automotive structural components are commonly protected using zinc coatings. However, the steel/zinc system creates the potential for liquid metal embrittlement during welding. Although liquid metal embrittlement cracks are known to form, the current literature does not include crack location when assessing crack severity. In this work, TRIP1100 joints showed that LME cracks decreased strength from 7.8 to 42.2%, depending on location, between the coated (cracked) and uncoated (non-cracked) condition. Liquid metal embrittlement cracks in critical locations were observed to propagate until fracture from lap shear testing. However, cracks in non-critically loaded areas were not part of the fracture path and did not result in a significant loss in strength. This shows LME crack location can be controlled to improve joint performance and vehicle safety. In addition, a model of lap shear testing in a cracked sample showed how the presence of a crack can affect the internal stress field depending on its location.

Similar content being viewed by others

References

A.I. Cooper, Materials Chemistry: Cooperative Carbon Capture, Nature, 2015, 519, p 295

M. Jakob and J. Hilaire, Unburnable Fossil-Fuel Reserves, Nature, 2015, 517, p 150

M. McNutt, Climate Change Impacts, Science, 2013, 341, p 435

B.F. Creutzig, P. Jochem, O.Y. Edelenbosch et al., Transport: A Roadblock to Climate Change Mitigation?, Science, 2015, 350, p 911–912

D. Parkes, D. Westerbaan, S.S. Nayak et al., Tensile Properties of Fiber Laser Welded Joints of High Strength Low Alloy and Dual-Phase Steels at Warm and Low Temperatures, Mater. Des., 2014, 56, p 193–199

D. Parkes, W. Xu, D. Westerbaan et al., Microstructure and Fatigue Properties of Fiber Laser Welded Dissimilar Joints Between High Strength Low Alloy and Dual-Phase Steels, Mater. Des., 2013, 51, p 665–675

W. Xu, D. Westerbaan, S.S. Nayak et al., Tensile and Fatigue Properties of Fiber Laser Welded High Strength Low Alloy and DP980 Dual-Phase Steel Joints, Mater. Des., 2013, 43, p 373–383

M. Kimchi and D.H. Phillips, Resistance Spot Welding, Fundamentals and Applications for the Automotive Industry, Morgan Claypool Publ., Columbus, 2017

Y.G. Kim, I.J. Kim, J.S. Kim et al., Evaluation of Surface Crack in Resistance Spot Welds of Zn-Coated Steel, Mater. Trans., 2014, 55, p 171–175

C. Jiang, A.K. Thompson, M.F. Shi et al., Liquid Metal Embrittlement in Resistance Spot Welds of AHSS Steels, AWS Prof Progr; 2003. p. 9A. Available from https://app.aws.org/conferences/abstracts/2003/09a.pdf

D. Bhattacharya, Liquid Metal Embrittlement During Resistance Spot Welding of Zn-Coated High-Strength Steels, Mater. Sci. Technol., 2018, 0, p 1–21. https://doi.org/10.1080/02670836.2018.1461595

K. Ina and H. Koizumi, Penetration of Liquid Metals into Solid Metals and Liquid Metal Embrittlement, Mater. Sci. Eng. A, 2004, 387-389, p 390–394

B. Joseph, F. Barbier, G. Dagoury et al., Rapid Penetration of Liquid Bi Along Cu Grain Boundaries, Scr. Mater., 1998, 39, p 775–781

G. Jung, I.S. Woo, D.W. Suh et al., Liquid Zn Assisted Embrittlement of Advanced High Strength Steels with Different Microstructures, Met. Mater. Int., 2016, 22, p 187–195

C. Beal, X. Kleber, D. Fabregue et al., Embrittlement of a Zinc Coated High Manganese TWIP Steel, Mater. Sci. Eng. A, 2012, 543, p 76–83

P. Marashi, M. Pouranvari, S.M.H. Sanaee et al., Relationship Between Failure Behaviour and Weld Fusion Zone Attributes of Austenitic Stainless Steel Resistance Spot Welds, Mater. Sci. Technol., 2008, 24, p 1506–1512

H. Zhang, X. Qiu, F. Xing et al., Failure Analysis of Dissimilar Thickness Resistance Spot Welded Joints in Dual-Phase Steels During Tensile Shear Test, Mater. Des., 2014, 55, p 366–372. https://doi.org/10.1016/j.matdes.2013.09.040

P. Russo Spena, M. De Maddis, G. D’Antonio et al., Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels, Metals (Basel), 2016, 6, p 270

M.I. Khan, M.L. Kuntz, and Y. Zhou, Effects of Weld Microstructure on Static and Impact Performance of Resistance Spot Welded Joints in Advanced High Strength Steels, Sci. Technol. Weld. Join., 2008, 13, p 294–304. https://doi.org/10.1179/174329308X271733

Y.J. Chao, Ultimate Strength and Failure Mechanism of Resistance Spot Weld Subjected to Tensile, Shear, or Combined Tensile/Shear Loads, J. Eng. Mater. Technol., 2003, 125, p 125

Y.J. Chao, Failure Mode of Spot Welds: Interfacial Versus Pullout, Sci. Technol. Weld. Join., 2003, 8, p 62–68. https://doi.org/10.1179/136217103225008955

D.-Y. Choi, S.-H. Uhm, C.M. Enloe et al., Liquid Metal Embrittlement of Resistance Spot Welded 1180TRIP Steel-effects of Crack Geometry on Weld Mechanical Performance, Mater. Sci. Technol., 2017. https://doi.org/10.7449/2017mst/2017/mst_2017_454_462

C. DiGiovanni, E. Biro, and N.Y. Zhou, Impact of Liquid Metal Embrittlement Cracks on Resistance Spot Weld Static Strength, Sci. Technol. Weld., 2019, 24, p 218–224. https://doi.org/10.1080/13621718.2018.1518363

Y.G. Kim, I.J. Kim, J.S. Kim et al., Evaluation of Surface Crack in Resistance Spot Welds of Zn-Coated Steel, Jpn. Inst. Met. Mater., 2014, 55, p 171–175

L. Boriwal, R.M. Sarviya, and M.M. Mahapatra, Failure modes of Spot Welds in Quasi–Static Tensile–Shear Loading of Coated Steel Sheets, Mater. Today Proc., 2017, 4, p 3672–3677. https://doi.org/10.1016/j.matpr.2017.02.261

American Welding Society, American Welding Society: Test Method for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials (AWS D 8.9M), 2012, p 1–107

M. Zhou, S. Hu, and H. Zhang, Critical Specimen Sizes for Tensile-Shear Testing of Steel Sheets, Weld. J., 1999, 78, p 305S–313S

K.-Y. Seo, J.-H. Kim, H.-S. Lee et al., Effect of Constitutive Equations on Springback Prediction Accuracy in the TRIP1180 Cold Stamping, Metals, 2017, 8, p 1–17. https://doi.org/10.3390/met8010018

N. Moës, J. Dolbow, and T. Belytschko, A Finite Element Method for Crack Growth Without Remeshing, Int. J. Numer. Methods Eng., 1999, 46, p 131–150

H.M. Westergaard, Bearing Pressures and Cracks, J. Appl. Mech., 1939, 6, p A49–A53

C.F. Shih and R.J. Asaro, Elastic–Plastic Analysis of Cracks on Bimaterial Interfaces: Part I—Small Scale Yielding, J. Appl. Mech., 1988, 55, p 299

Funding

This work was supported by Natural Science and Engineering Research Council of Canada; and the International Zinc Association.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

DiGiovanni, C., Han, X., Powell, A. et al. Experimental and Numerical Analysis of Liquid Metal Embrittlement Crack Location. J. of Materi Eng and Perform 28, 2045–2052 (2019). https://doi.org/10.1007/s11665-019-04005-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04005-2