Abstract

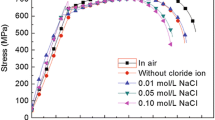

The coupling effect of stray AC (alternating current) + DC (direct current) and tensile stress-induced X70 pipeline corrosion is complicated with its mechanism uncovered. In this work, the corrosion behavior of X70 pipeline steel under three different corrosion (including an individual AC corrosion, mixed AC + 150 MPa tensile stress corrosion, coupling effect of AC + a 30 A/m2 DC interference and 150 MPa tensile stress corrosion) conditions in Dagang soil simulated solution was investigated by COMSOL Multiphysics software simulation, electrochemical tests, scanning electron microscope and other techniques. The results indicated that with the increase in AC density, the open-circuit potential of the X70 steel samples was negatively shifted and corrosion rate increased in three different corrosion conditions. The corrosion rates of X70 steel samples under individual AC interference were almost unchanged when 150.9 MPa tensile stress was applied. When applying 30 A/m2 DC interference, the corrosion rate of X70 steel increases significantly. Therefore, the factors affecting corrosion performance of X70 pipeline steel were DC > AC > stress. Under individual AC interference, uniform corrosion occurred on the X70 steel at an AC current density of less than 30 A/m2, while the pitting corrosion occurred at an AC current density of greater than 100 A/m2. The application of tensile stress and DC had a certain inhibitory effect on pitting corrosion.

Similar content being viewed by others

References

S.R. Allahkaram, M. Isakhani-Zakaria, M. Derakhshani et al., Investigation on Corrosion Rate and a Novel Corrosion Criterion for Gas Pipelines Affected by Dynamic Stray Current, J. Nat. Gas Sci. Eng., 2015, 26, p 453–460

A.O.S. Solgaard, M. Carsana, M.R. Geiker et al., Experimental Observations of Stray Current Effects on Steel Fibres Embedded in Mortar, Corros. Sci., 2013, 74, p 1–12

Q. Zhu, A. Cao, Z. Wang et al., Stray Current Corrosion in Buried Pipeline, Anti-Corros. Methods Mater., 2013, 58(5), p 234–237

L. Bertolini, M. Carsana, and P. Pedeferri, Corrosion Behaviour of Steel in Concrete in the Presence of Stray Current, Corros. Sci., 2007, 49(3), p 1056–1068

T.J. Barlo and A.D. Zdunek, Stray Current Corrosion in Electrified Rail System-Final Report. (Infrastructure Technology Institute, Evanston Illinois, 1995), pp. 1–47.

Z.G. Chen, C.K. Qin, J.X. Tang et al., Experiment Research of Dynamic Stray Current Interference on Buried Gas Pipeline from Urban Rail Transit, J. Nat. Gas Sci. Eng., 2013, 15(6), p 76–81

H.R. Hanson, AC Corrosion on a Pipeline Located in an HVAC Utility Corridor, in Corrosion (2004).

M. Ouadah, O. Touhami, R. Ibtiouen et al., Corrosive Effects of the Electromagnetic Induction Caused by the High Voltage Power Lines on Buried X70 Steel Pipelines, Int. J. Electr. Power Energy Syst., 2017, 91, p 34–41

X.H. Wang, J.Y. Liu, H.E. Ren-Yang et al., Detection Method of Stray Current to Urban Buried Gas Pipelines, in Pipeline Technique & Equipment (2010).

S.Y. Xu, W. Li, and Y.Q. Wang, Effects of Vehicle Running Mode on Rail Potential and Stray Current in DC Mass Transit Systems, IEEE Trans. Veh. Technol., 2013, 62(8), p 3569–3580

Z.X. Tang, Z.J. Wen, C.S. Li et al., Corrosion Behavior of Carbon Steel in Interference of Stray Current and Cathodic Protection, Surf. Technol., 2015, 44(12), p 12–18

M. Ouadah, O. Touhami, R. Ibtiouen et al., Method for Diagnosis of the Effect of AC on the X70 Pipeline Due to an Inductive Coupling Caused by HVPL, IET Sci. Meas. Technol., 2017, 11(6), p 766–772

Y. Li, Effects of Stray AC Interference on Corrosion Behavior of X70 Pipeline Steel in a Simulated Marine Soil SolutionJ], Int. J. Electrochem. Sci., 2017, 12(3), p 1829–1845

Z. Jiang, Y. Du, M. Lu et al., New Findings on the Factors Accelerating AC Corrosion of Buried Pipeline, Corros. Sci., 2014, 81(81), p 1–10

B. Mccollum and G.H. Ahlborn, The Influence of Frequency of Alternating or Infrequently Reversed Current on Electrolytic Corrosion, Proc. Am. Inst. Electr. Eng., 2013, 35(3), p 371–397

S. Goidanich, L. Lazzari, and M. Ormellese, AC Corrosion. Part 2: Parameters Influencing Corrosion Rate, Corros. Sci., 2010, 52(3), p 916–922

X. Wang and X. Wang, Effects of Stray AC on Delamination of Epoxy Coatings with Defects in 3.5% NaCl Solution, Int. J. Electrochem. Sci., 2017, 12(7), p 6520–6534

X. Wang, X. Tang, L. Wang et al., Corrosion Behavior of X80 Pipeline Steel under Coupling Effect of Stress and Stray Current, Int. J. Electrochem. Sci., 2014, 9(8), p 4574–4588

Y. Chen, Cathodic Protection Parameters of X65 and X80 Pipeline Steels in Dagang Simulated Soil Solution, Surf. Technol., 2018, 47(6), p 218–223

Z. Liu, Z. Cui, X. Li et al., Mechanistic Aspect of Stress Corrosion Cracking of X80 Pipeline Steel Under Non-Stable Cathodic Polarization, Electrochem. Commun., 2014, 48, p 127–129

N. Winzer, A. Atrens, G. Song et al., A Critical Review of the Stress Corrosion Cracking (SCC) of Magnesium Alloys, Adv. Eng. Mater., 2010, 7(8), p 659–693

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Mechanistic Aspect of Near-Neutral pH Stress Corrosion Cracking of Pipelines Under Cathodic Polarization, Corros. Sci., 2012, 55(2), p 54–60

G.V. Boven, R. Rogge, and W. Chen, Residual Stress and Stress Corrosion Cracking of High Pressure Hydrocarbon Transmission Pipelines, in International Pipeline Conference (2007), pp. 725–742.

Y. Wei, H. Feng, H.U. Qian et al., Influences of Applied Tensile Stress on the Pitting Electrochemical Behavior of X80 Pipeline Steel, J. Chin. Soc. Corros. Protect., 2013, 33(4), p 277–282

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Electrochemical State Conversion Model for Occurrence of Pitting Corrosion on a Cathodically Polarized Carbon Steel in a Near-Neutral pH Solution, Electrochim. Acta, 2011, 56(11), p 4167–4175

M. Büchler, Alternating Current Corrosion of Cathodically Protected Pipelines: Discussion of the Involved Processes and Their Consequences on the Critical Interference Values, Mater. Corros., 2015, 63(12), p 1181–1187

M. Büchler, T. Watari, and W.H. Smyrl, Investigation of the Initiation of Localized Corrosion on Aluminum Alloys by Using Fluorescence Microscopy, Corros. Sci., 2000, 42(9), p 1661–1668

L.Y. Xu and Y.F. Cheng, An Experimental Investigation of Corrosion of X100 Pipeline Steel Under Uniaxial Elastic Stress in a Near-Neutral pH Solution, Corros. Sci., 2012, 59(3), p 103–109

L. Yang, N. Hort, R. Willumeit et al., Effects of Corrosion Environment and Proteins on Magnesium Corrosion, Br. Corros. J., 2014, 47(5), p 335–339

X.U. Chun-chun and L. Chi, Electrochemical Behavior of X70 Pipeline Steel in Carbonate-Bicarbonate Solution, Corros. Sci. Protect. Technol., 2004, 16(5), p 268–271

F. Mansfeld, Tafel Slopes and Corrosion Rates Obtained in the pre-Tafel Region of Polarization Curves, Corros. Sci., 2005, 47(12), p 3178–3186

U. Bertocci, AC Induced Corrosion. The Effect of an Alternating Voltage on Electrodes Under Charge-Transfer Control, Corrosion, 1979, 35:5(5), p 1281–1287

L. Liang, Y. He, H. Song et al., Effect of Hydration Pretreatment on Tunnel Etching Behaviour of Aluminium Foil, Corros. Sci., 2013, 70(3), p 180–187

Y. Guo, T. Meng, D. Wang et al., Experimental Research on the Corrosion of X Series Pipeline Steels Under Alternating Current Interference, Eng. Fail. Anal., 2017, 78, p 87–98

S.B. Lalvani and X.A. Lin, A Theoretical Approach for Predicting AC-Induced Corrosion, Corros. Sci., 1994, 36(6), p 1039–1046

X. Wang, X. Tang, L. Wang et al., Corrosion Behavior of X80 Pipeline Steel under Coupling Effect of Stress and Stray Current, Int. J. Electrochem. Sci., 2014, 9(8), p 4574–4588

C. Wen, J. Li, S. Wang et al., Experimental Study on Stray Current Corrosion of Coated Pipeline Steel, J. Nat. Gas Sci. Eng., 2015, 27, p 1555–1561

M. Büchler and H.-G. Schöneich, Investigation of Alternating Current Corrosion of Cathodically Protected Pipelines: Development of a Detection Method, Mitigation Measures, and a Model for the Mechanism, Corrosion, 2012, 65(9), p 578–586

Z. Tang, S. Hong, W. Xiao et al., Characteristics of Iron Corrosion Scales Established Under Blending of Ground, Surface, Saline Waters and Their Impacts on Iron Release in the Pipe Distribution System, Corros. Sci., 2006, 48(2), p 322–342

Y.B. Guo, C. Liu, D.G. Wang et al., Effects of Alternating Current Interference on Corrosion of X60 Pipeline Steel, Petrol. Sci., 2015, 12(2), p 316–324

Y. Wei, H. Feng, H.U. Qian et al., Influences of Applied Tensile Stress on the Pitting Electrochemical Behavior of X80 Pipeline Steel, J. Chin. Soc. Corros. Protect., 2013, 33(4), p 277–282

Acknowledgments

This study was supported by National Natural Science Foundation of China (No. 51471011) and “Rixin Scientist” of Beijing University of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Wang, Z., Chen, Y. et al. Research on the Corrosion Behavior of X70 Pipeline Steel Under Coupling Effect of AC + DC and Stress. J. of Materi Eng and Perform 28, 1958–1968 (2019). https://doi.org/10.1007/s11665-019-03959-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03959-7