Abstract

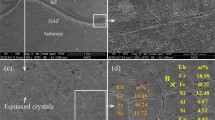

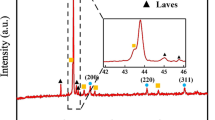

AISI1045 steel is widely used in mechanical engineering. In spite of the favorable toughness and strength, the surface properties of AISI1045 steel, such as hardness, wear resistance and corrosion resistance, are not ideal. Therefore, surface modification of AISI1045 is necessary, especially for the parts suffering severe work condition. Laser cladding is a promising surface modification technology. In this work, the AlCoCrFeNiTi high-entropy alloy (HEA) coatings were prepared on the AISI1045 steel to improve its surface properties. Metallurgical bonding is obtained between the coating and the substrate. The microstructure and surface properties of the coating were characterized by scanning electron microscope, energy-dispersive spectrometry, x-ray diffraction, electrochemical workstation, microhardness tester and pin-on-ring wear tester. The microstructure of the coating produced by laser cladding is dendritic. The AlCoCrFeNiTi HEA coating is mainly composed of disordered body-centered cubic phase (Fe-Cr), ordered B2 phase (AlNi) and intermetallic phase (Ti-rich). The coating shows excellent abrasion resistance and corrosion resistance in comparison with the substrate. The maximum microhardness of the coating reaches approximately 865 HV, which is 4.5 times of AISI1045 steel.

Similar content being viewed by others

References

S.Y. Dong, B.S. Xu, L.Z. Du, and Y. Hua, Sand-Wear Resistance of Brush Electroplated Nanocomposite Coating in Oil and Its Application to Remanufacturing, Cent. South. Univ., 2005, 12(s2), p 176–180

T.K. Cao and Z.J. Xiao, Tribological Behaviors of Self-lubricating Coating Prepared by Electrospark Deposition, Tribol. Lett., 2014, 56(2), p 231–237

Z.Z. Fu and R. Koc, TiNiFeCrCoAl High-Entropy Alloys as Novel Metallic Binders for TiB2-TiC Based Composites, Mater. Sci. Eng. A, 2018, 735, p 302–309

G.L. Li, Y.L. Li, T.S. Dong, H.D. Wang, X.D. Zheng, and X.K. Zhou, Microstructure and Wear Resistance of TIG Remelted NiCrBSi Thick Coatings, Adv. Mater. Sci. Eng., 2018, 2018, p 1–10

J.B. Cheng, X.B. Liang, Z.H. Wang, and B.S. Xu, Synthesis and Erosion Behaviors of Nanoscale Coatings Prepared by Wire Arc Spraying, Rare Met. Mater. Eng., 2012, 41(s1), p 144–147

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303

O.N. Senkov, S.V. Senkova, D.M. Dimiduk, C. Woodward, and D.B. Miracle, Oxidation Behavior of a Refractory NbCrMo0.5Ta0.5TiZr Alloy, J. Mater. Sci., 2012, 47(18), p 6522–6534

J.B. Li, B. Gao, S. Tang, B. Liu, Y. Liu, Y. Wang, and J.W. Wang, High Temperature Deformation Behavior of Carbon-Containing FeCoCrNiMn High Entropy Alloy, J. Alloys Compd., 2018, 747, p 571–579

R. Zhou, G. Chen, B. Liu, J.W. Wang, L.L. Han, and Y. Liu, Microstructures and Wear Behaviour of (FeCoCrNi)1−x(WC)x, High Entropy Alloy Composites, Int. J. Refract. Met. Hard Mater., 2018, 75, p 56–62

M. Cheng, X.H. Shi, H.J. Yang, P.K. Liaw, M.C. Gao, J.A. Hawk, and J.W. Qiao, Wear Behavior of Al0.6CoCrFeNi High-Entropy Alloys: Effect of Environments, J. Mater. Res., 2018, 33(19), p 3310–3320

A. Manzoni, H. Daoud, R. Völkl, U. Glatzel, and N. Wanderka, Phase Separation in Equiatomic AlCoCrFeNi High-Entropy Alloy, Ultramicroscopy, 2013, 132(3), p 212–215

Y.X. Wang, Y.J. Yang, H.J. Yang, M. Zhang, S.G. Ma, and J.W. Qiao, Microstructure and Wear Properties of Nitrided AlCoCrFeNi High-Entropy Alloy, Mater. Chem. Phys., 2017, 210(SI), p 233–239

D.Y. Lin, N.N. Zhang, B. He, G.W. Zhang, Y. Zhang, and D.Y. Li, Tribological Properties of FeCoCrNiAlBx High-Entropy Alloys Coating Prepared by Laser Cladding, J. Iron Steel Res. Int., 2017, 24(2), p 184–189

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.Q. Hu, Synthesis and Properties of Multiprincipal Component AlCoCrFeNiSix Alloys, Mater. Sci. Eng. A, 2010, 527(27), p 7210–7214

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Solid Solution Alloys of AlCoCrFeNiTix with Excellent Room-Temperature Mechanical Properties, Appl. Phys. Lett., 2007, 90(18), p 253

B. He, N.N. Zhang, D.Y. Lin, Y. Zhang, F.Y. Dong, and D.Y. Li, The Phase Evolution and Property of FeCoCrNiAlTix High-Entropy Alloying Coatings on Q253 via Laser Cladding, Coatings, 2017, 7(10), p 157

Y. Yuan, J. Wang, J.S. Li, J. Yang, H.C. Kou, and W.M. Liu, Tribological Behavior of AlCoCrFeNi(Ti0.5) High Entropy Alloys Under Oil and MACs Lubrication, J. Mater. Sci. Technol., 2016, 32, p 470–476

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, and J.W. Yeh, Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy, High-Entropy Alloys, Acta Mater., 2011, 59(16), p 6308–6317

L.H. Tian, W. Xiong, C. Liu, S. Lu, and M. Fu, Microstructure and Wear Behavior of Atmospheric Plasma-Sprayed AlCoCrFeNiTi High-Entropy Alloy Coating, J. Mater. Eng. Perform., 2016, 25(12), p 1–9

V. Soare, D. Mitrica, I. Constantin, V. Badilita, F. Stoiciu, A.M.J. Popescu, and I. Carcea, Influence of Remelting on Microstructure, Hardness and Corrosion Behaviour of AlCoCrFeNiTi High Entropy Alloy, Mater. Sci. Tech. Lond., 2015, 31(10), p 1194–1200

V. Ocelík, N. Janssen, S.N. Smith, and J.T.M.D. Hosson, Additive Manufacturing of High-Entropy Alloys by Laser Processing, Jom-Us, 2016, 68(7), p 1810–1818

Z.T. Gan, H. Liu, S.X. Li, X.L. He, and G. Yu, Modeling of Thermal Behavior and Mass Transport in Multi-layer Laser Additive Manufacturing of Ni-Based Alloy on Cast Iron, Int. J. Mass. Trans., 2017, 11, p 709–722

Y. Hu, X. He, G. Yu, Z.F. Ge, C.Y. Zheng, and W.J. Ning, Heat and Mass Transfer in Laser Dissimilar Welding of Stainless Steel and Nickel, Appl. Surf. Sci., 2012, 258(15), p 5914–5922

K.B. Zhang and Z.Y. Fu, Effects of Annealing Treatment on Phase Composition and Microstructure of CoCrFeNiTiAlx High-Entropy Alloys, Intermetallics, 2012, 22(3), p 24–32

H. Liu, J.B. Hao, Z.T. Han, G. Yu, X.L. He, and H.F. Yang, Microstructural Evolution and Bonding Characteristic in Multi-layer Laser Cladding of NiCoCr Alloy on Compacted Graphite Cast Iron, J. Mater. Process. Technol., 2016, 232, p 153–164

Z.J. Wang, W.F. Qiu, Y. Yang, and C.T. Liu, Atomic-Size and Lattice-Distortion Effects in Newly Developed High-Entropy Alloys with Multiple Principal Elements, Intermetallics, 2015, 64, p 63–69

K. Rzyman, Z. Moser, R.E. Watson, and M. Weinert, Enthalpies of Formation of AlNi: Experiment Versus Theory, J. Phase Equilib., 1998, 19(2), p 106–111

Y. Yu, W.M. Liu, T.B. Zhang, J.S. Li, J. Wang, H.C. Kou, and J. Li, Microstructure and Tribological Properties of AlCoCrFeNiTi0.5 High-Entropy Alloy in Hydrogen Peroxide Solution, Metall. Mater. Trans. A, 2014, 45(1), p 201–207

S. Singh, N. Wanderka, B.S. Murty, U. Glatzel, and J. Banhart, Decomposition in Multi-component AlCoCrCuFeNi High-Entropy Alloy, Acta Mater., 2011, 59(1), p 182–190

X. Yang and Y. Zhang, Prediction of High-Entropy Stabilized Solid-Solution in Multi-component Alloys, Mater. Chem. Phys., 2012, 132(2–3), p 233–238

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys, J. Appl. Phys., 2011, 109(10), p 213

K.J. Huang, X. Lin, Y.Y. Wang, C.S. Xie, and T.M. Yue, Microstructure and Corrosion Resistance of Cu0.9NiAlCoCrFe High Entropy Alloy Coating on AZ91D Magnesium Alloys by Laser Cladding, Mater. Res. Innov., 2014, 18(S2), p 1008–1011

X.W. Qiu, Y.P. Zhang, L. He, and C.G. Liu, Microstructure and Corrosion Resistance of AlCrFeCuCo High Entropy Alloy, J. Alloys Compd., 2013, 549(2), p 195–199

Acknowledgments

The authors acknowledge the Fundamental Research Funds for the Central Universities (2017QNA18) and the Project Funded by Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, H., Liu, J., Chen, P. et al. Microstructure and Properties of AlCoCrFeNiTi High-Entropy Alloy Coating on AISI1045 Steel Fabricated by Laser Cladding. J. of Materi Eng and Perform 28, 1544–1552 (2019). https://doi.org/10.1007/s11665-019-03949-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03949-9