Abstract

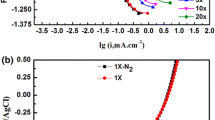

Pitting corrosion of high-strength steel 10Ni8CrMoV under square wave polarization (SWP) in simulated deep-sea environment is investigated and the possible mechanism is proposed. The results show that potential perturbation generates periodic intensification effect on both anodic and cathodic processes by frequently breaking the electrode equilibrium state. The intensity of periodic intensification effect essentially depends on the concentration gradient of Fe2+ cations at the steel/solution interface which acts as the forced electrochemical oscillator. The concentration gradient and the resulting concentration polarization effect increase periodically with the increase in SWP potential range. The morphology observation of the pitting and electric charge calculation indicate that the periodic intensification effect can promote the initiation and growth of pits by enhancing the anodic dissolution even under cathodic protection, but it is ineffective below the hydrogen evolution potential. The decrease in either upper or lower potential can mitigate anodic dissolution. Through the statistical analysis of pitting size, it is found that the wide potential range tends to activate the metastable pitting formed under hydrostatic pressure, forming densely distributed pitting. Meanwhile, it is more favorable to the formation of fully grown pits with high size dispersion degree when the proportion of electric charge in the anodic process is higher.

Similar content being viewed by others

References

W. Mai, S. Soghrati, and R.G. Buchheit, A Phase Field Model for Simulating the Pitting Corrosion, Corros. Sci., 2016, 110, p 157–166

R.E. Melchers, Pitting Corrosion of Mild steel in Marine Immersion Environment. Part 1: Maximum Pit Depth, Corrosion, 2004, 60(9), p 824–836

R.E. Melchers and R. Jeffrey, Early Corrosion of Mild Steel in Seawater, Corros. Sci., 2005, 47(7), p 1678–1693

F. Gan, Z.W. Sun, G. Sabde, and D.T. Chin, Cathodic Protection to Mitigate External Corrosion of Underground Steel Pipe Beneath Disbonded Coating, Corrosion, 1994, 50(10), p 804–816

I.A. Metwally and A.H. Al-Badi, Analysis of Different Factors Affecting Cathodic Protection for Deep Well Casings, Mater. Corros., 2015, 61(3), p 245–251

D.T. Chin and T.W. Fu, Corrosion by Alternating Current: A Study of the Anodic Polarization of Mild Steel in Na2SO4 Solution, Corrosion, 1979, 35(11), p 514–523

D.A. Jones, Effect of Alternating Current on Corrosion of Low Alloy and Carbon Steels, Corrosion, 1978, 34(12), p 428–433

R.W. Bosch and W.F. Bogaerts, A Theoretical Study of AC-Induced Corrosion Considering Diffusion Phenomena, Corros. Sci., 1998, 40(2), p 323–336

S.B. Lalvani and X. Lin, A Revised Model for Predicting Corrosion of Materials Induced by Alternating Voltages, Corros. Sci., 1996, 38(10), p 1709–1719

I.A. Metwally, H.M. Al-Mandhari, A. Gastli, and Z. Nadir, Factors Affecting Cathodic-Protection Interference, Eng. Anal. Bound. Elem., 2007, 31(6), p 485–493

S. Goidanich, L. Lazzari, and M. Ormellese, AC Corrosion—Part 1: Effects on Overpotentials of Anodic and Cathodic Processes, Corros. Sci., 2010, 52(2), p 491–497

L.W. Wang, X.H. Wang, Z.Y. Cui, Z.Y. Liu, C.W. Du, and X.G. Li, Effect of Alternating Voltage on Corrosion of X80 and X100 Steels in A Chloride Containing Solution—Investigated by AC Voltammetry Technique, Corros. Sci., 2014, 86, p 213–222

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Understand the Occurrence of Pitting Corrosion of Pipeline Carbon Steel under Cathodic Polarization, Electrochim. Acta, 2012, 60(1), p 259–263

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Electrochemical State Conversion Model for Occurrence of Pitting Corrosion on A Cathodically Polarized Carbon Steel in A Near-Neutral pH Solution, Electrochim. Acta, 2011, 56(11), p 4167–4175

R.K. Gupta, M.Y.J. Tan, J. Esquivel, and M. Forsyth, Occurrence of Anodic Current and Corrosion of Steel in Aqueous Media under Fluctuating Cathodic Protection Potentials, Corrosion, 2016, 72(10), p 1243–1251

Y. Huo, M.Y.J. Tan, and M. Forsyth, Visualising Dynamic Passivation and Localized Corrosion Processes Occurring on Buried Steel Surfaces under the Effect of Anodic Transients, Electrochem. Commun., 2016, 66, p 21–24

R. Cao, W. Feng, Y. Peng, W.S. Du, Z.L. Tian, and J.H. Chen, Investigation of Abnormal High Impact Toughness in Simulated Welding CGHAZ of A 8%Ni 980 MPa High Strength Steel, Mater. Sci. Eng. A, 2010, 528(2), p 631–642

L. Fan, K.K. Ding, W.M. Guo, P.H. Zhang, and L.K. Xu, 静水压力和预应力对新型 Ni-Cr-Mo-V 高强钢腐蚀行为的影响 (Effect of Hydrostatic Pressure and Pre-Stress on Corrosion Behavior of A New Type Ni-Cr-Mo-V High Strength Steel), Acta Metall. Sin., 2016, 52(6), p 679–788 (in Chinese)

L. Fan, K.K. Ding, P.H. Zhang, W.M. Guo, K. Pang, and L.K. Xu, Electrochemical Characterization on the Potential Dependent Stress Corrosion Cracking Mechanism of 10Ni8CrMoV High Strength Steel, ISIJ Int., 2017, 57(5), p 888–894

W.M. Tian, N. Du, S.M. Li, S.B. Chen, and Q.Y. Wu, Metastable Pitting Corrosion of 304 Stainless Steel in 3.5% NaCl Solution, Corros. Sci., 2014, 85(4), p 372–379

D.K. Kim, S. Muralidharan, T.H. Ha, J.H. Bae, Y.C. Ha, H.G. Lee, and J.D. Scantlebury, Electrochemical Studies on the Alternating Current Corrosion of Mild Steel under Cathodic Protection Condition in Marine Environments, Electrochim. Acta, 2006, 51(25), p 5259–5267

Z.Y. Liu, X.G. Li, C.W. Du, and Y.F. Cheng, Local Additional Potential Model for Effect of Strain Rate on SCC of Pipeline Steel in an Acidic Soil Solution, Corros. Sci., 2009, 51(12), p 2863–2871

Y.F. Cheng and J.L. Luo, Statistical Analysis of Metastable Pitting Events on Carbon Steel, Br. Corros. J., 2000, 35(2), p 125–130

R.E. Melchers, Statistical Characterization of Pitting Corrosion. Part 1: Data Analysis, Corrosion, 2005, 61(8), p 766–777

P. Refait, A.M. Grolleau, M. Jeannin, E. François, and R. Sabot, Localized Corrosion of Carbon Steel in Marine Media: Galvanic Coupling and Heterogeneity of the Corrosion Product Layer, Corros. Sci., 2016, 111, p 583–595

R. Jeffrey and R.E. Melchers, Corrosion of Vertical Mild Steel Strips in Seawater, Corros. Sci., 2009, 51(10), p 2291–2297

T. Okstad, Ø. Rannestad, R. Johnsen, and K. Nisancioglu, Significance of Hydrogen Evolution During Cathodic Protection of Carbon Steel in Seawater, Corrosion, 2007, 63(9), p 857–865

C.W. Du, L.W. Wang, Z.Y. Liu, Z.Y. Cui, and X.G. Li, Influence of Alternating Voltages on Passivation and Corrosion Properties of X80 Pipeline Steel in High pH 0.5 mol/L NaHCO3 + 0.25 mol/L Na2CO3 Solution, Br. Corros. J., 2015, 50(3), p 248–255

A.M. Beccaria and G. Poggi, Influence of Hydrostatic Pressure on Pitting of Aluminum in Sea Water, Br. Corros. J., 1985, 20(4), p 183–186

L.W. Wang, L.J. Cheng, J.R. Li, Z.F. Zhu, S.W. Bai, and Z.Y. Cui, Combined Effect of Alternating Current Interference and Cathodic Protection on Pitting Corrosion and Stress Corrosion Cracking Behavior of X70 Pipeline Steel in Near-Neutral pH Environment, Materials, 2018, 11(4), p 465

L. Ramaley and M.S.K. Jr., Theory of Square Wave Voltammetry, Anal. Chem., 1969, 41(11), p 1362–1365

Z. Nagy, P.J. Hernes, M. Minkoff, G.K. Leaf, and R.H. Land, Effect of Diffusion Layer Structure on the Determination of Corrosion Rates from DC Transient Measurements, J. Electrochem. Soc., 1989, 136(10), p 2816–2820

M. Zhu, C.W. Du, X.G. Li, Z.Y. Liu, S.R. Wang, J.K. Li, and D.W. Zhang, Effect of AC Current Density on Stress Corrosion Cracking Behavior of X80 Pipeline Steel in High pH Carbonate/Bicarbonate Solution, Electrochim. Acta, 2014, 117(4), p 351–359

M. Pagitsas and D. Sazou, The Effect of a Sinusoidal Potential Perturbation on the Active–Passive Transition Region of Cobalt in A Phosphoric Acid Solution, J. Electroanal. Chem., 1995, 386(1–2), p 89–99

Z.Y. Liu, Z.Y. Cui, X.G. Li, C.W. Du, and Y.Y. Xing, Mechanistic Aspect of Stress Corrosion Cracking of X80 Pipeline Steel under Non-Stable Cathodic Polarization, Electrochem. Commun., 2014, 48, p 127–129

Z.Y. Liu, L.J. Lu, Y.Z. Huang, and X.G. Li, Mechanistic Aspect of Non-steady Electrochemical Characteristic during Stress Corrosion Cracking of An X70 Pipeline Steel in Simulated Underground Water, Corrosion, 2014, 70(7), p 678–685

B. Gu, J. Luo, and X. Mao, Hydrogen-Facilitated Anodic Dissolution-Type Stress Corrosion Cracking of Pipeline Steels in Near-Neutral pH Solution, Corrosion, 2012, 55(1), p 96–106

Z.Y. Cui, Z.Y. Liu, L.W. Wang, H.C. Ma, C.W. Du, X.G. Li, and X. Wang, Effect of pH Value on the Electrochemical and Stress Corrosion Cracking Behavior of X70 Pipeline Steel in the Dilute Bicarbonate Solutions, J. Mater. Eng. Perform., 2015, 24(11), p 4400–4408

Z.Y. Cui, Z.Y. Liu, L.W. Wang, C.W. Du, and X. Wang, Effect of Plastic Deformation on the Electrochemical and Stress Corrosion Cracking Behavior of X70 Steel in Near-Neutral pH Environment, Mater. Sci. Eng. A, 2016, 677, p 259–273

S.Y. Paredes-Dugarte and B. Hidalgo-Prada, Statistical Analysis of the Optical Interferometry of Pitting Process in Aluminum 3003 Sheets Exposed to Saline Environment, Proc. Mater. Sci., 2015, 8, p 82–90

Acknowledgments

This work was financially supported by the Chinese Defense Technical Basis Program of Science, Technology and Industry (Grant No.: JSHS2017207C001) and Qingdao Basic Application Research Program (Grant No.: 16-5-1-14-jch).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Fan, L., Ding, K., Zhang, P. et al. Pitting Corrosion of 10Ni8CrMoV High-Strength Steel Induced by a Potential Perturbation. J. of Materi Eng and Perform 27, 5794–5802 (2018). https://doi.org/10.1007/s11665-018-3660-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3660-8