Abstract

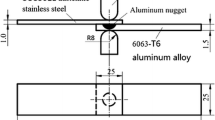

The microstructure and mechanical property of resistance spot-welded joints of steel and aluminum were studied by using process tapes. The steel/aluminum joint consists mainly of aluminum nugget and interface zone. The liquid nugget solidification has an epitaxial growth characteristic, and the interface zone displays a double-layer structure, Fe2Al5 layer at steel side and Fe4Al13 layer at aluminum nugget side. Compared with joints without process tape, the joint nugget diameter and tensile shear load increased by 35.45 and 10.98%, respectively, and its indentation ratio decreased by 56.25% due to the process tapes increasing heat input, producing larger nugget diameter and continuous interface layer, and protecting against deep indentation. The joining area of intermetallic layer and aluminum nugget is weak link in the joint. It is favorable to use the process tapes for improving welding quality, raising joint strength, and energy saving.

Similar content being viewed by others

References

J. Sun, Q. Yan, W. Gao, and J. Huang, Investigation of Laser Welding on Butt Joints of Al/Steel Dissimilar Materials, Mater. Des., 2015, 83, p 120-128

R. Hörhold, M. Müller, M. Merklein, and G. Meschut, Mechanical Properties of an Innovative Shear-Clinching Technology for Ultra-High-Strength Steel and Aluminium in Lightweight Car Body Structures, Weld. World, 2016, 60, p 1-8

A. Bouayad, Ch Gerometta, A. Belkebir, and A. Ambair, Kinetic Interactions Between Solid Iron and Molten Aluminum, Mater. Sci. Eng. A, 2003, 363, p 53-61

G. Sierra, P. Peyre, F.D. Beaume, D. Stuart, and G. Fras, Galvanised Steel to Aluminium Joining by Laser and GTAW Processes, Mater. Charact., 2008, 59(12), p 1705-1715

S.W. Mei, M. Gao, J. Yan, C. Zhang, G. Li, and X.Y. Zeng, Interface Properties and Thermodynamic Analysis of Laser-Arc Hybrid Welded Al/Steel Joint, Sci. Technol. Weld. Join., 2013, 18, p 293-300

M.K. Karfoul, G.J. Tatlock, and R.T. Murray, The Behaviour of Iron and Aluminium During the Diffusion Welding of Carbon Steel to Aluminium, J. Mater. Sci., 2007, 42(14), p 5692-5699

H. Shi, S. Qiao, R. Qiu, and X.Z.H. Yu, Effect of Welding Time on the Joining Phenomena of Diffusion Welded Joint Between Aluminum Alloy and Stainless Steel, Mater. Manuf. Process., 2012, 27(12), p 1366-1369

S. Kundu, D. Roy, R. Bhola, D. Bhattacharjee, and B. Mishra, Microstructure and Tensile Strength of Friction Stir Welded Joints Between Interstitial Free Steel and Commercially Pure Aluminium, Mater. Des., 2013, 50, p 370-375

M. Shakil, N.H. Tariq, M. Ahmad, M.A. Choudhary, J.I. Akhter, and S.S. Babue, Effect of Ultrasonic Welding Parameters on Microstructure and Mechanical Properties of Dissimilar Joints, Mater. Des., 2014, 55(6), p 263-273

T. Watanabe, H. Sakuyama, and A. Yanagisawa, Ultrasonic Welding Between Mild Steel Sheet and Al-Mg Alloy Sheet, J. Mater. Process. Technol., 2009, 209(15-16), p 5475-5480

H. Yu, Z. Xu, Z. Fan, Z. Zhao, and C. Li, Mechanical Property and Microstructure of Aluminum Alloy-Steel Tubes Joint by Magnetic Pulse Welding, Mater. Sci. Eng. A Struct., 2013, 561(3), p 259-265

J.Y. Shim, I.S. Kim, K.J. Lee, and B.Y. Kang, Experimental and Numerical Analysis on Aluminum/Steel Pipe Using Magnetic Pulse Welding, Met. Mater. Int., 2011, 17(6), p 957-961

H. Dong, W. Hu, Y. Duan, X. Wang, and C. Dong, Dissimilar Metal Joining of Aluminum Alloy to Galvanized Steel with Al-Si, Al-Cu, Al-Si-Cu and Zn-Al Filler Wires, J. Mater. Process. Technol., 2012, 212, p 458-464

H. Zhang and J. Liu, Microstructure Characteristics and Mechanical Property of Aluminum Alloy/Stainless Steel Lap Joints Fabricated by MIG Welding-Brazing Process, Mater. Sci. Eng. A, 2011, 528, p 6179-6185

Q. Chang, D. Sun, X. Gu, and H. Li, Microstructures and Mechanical Properties of Metal Inert-Gas Arc Welded Joints of Aluminum Alloy and Ultrahigh Strength Steel Using Al-Mg and Al-Cu Fillers, J. Mater. Res., 2017, 32(3), p 666-676

A. Kouadri-David, Study of Metallurgic and Mechanical Properties of Laser Welded Heterogeneous Joints Between DP600 Galvanised Steel and Aluminium 6082, Mater. Des., 2014, 54(54), p 184-195

R. Cao, J.H. Sun, J.H. Chen, and P.C. Wang, Cold Metal Transfer Joining of Aluminum AA6061-T6-to-Galvanized Boron Steel, J. Manuf. Sci. E, 2014, 136(5), p 351-373

Y.B. Liu, Q.J. Sun, J.P. Liu, S.J. Wang, and J.C. Feng, Effect of Axial External Magnetic Field on Cold Metal Transfer Welds of Aluminum Alloy and Stainless Steel, Mater. Lett., 2015, 152, p 29-31

Z. Lei, X. Wang, A. You, G. Qin, W. Wang, and S.Y. Lin, Research on Fusion-Brazing Joining Between Aluminum and Steel by Laser-MIG Hybrid Welding, Rare Met. Mater. Eng., 2009, 38(12), p 229-233

C. Thomy and F. Vollertsen, Laser-Mig Hybrid Welding of Aluminium to Steel—Effect of Process Parameters on Joint Properties, Weld. World, 2012, 56(5-6), p 124-132

J. Yan, M. Gao, and X.Y. Zeng, Study on Microstructure and Mechanical Properties of 304 Stainless Steel Joints by TIG, Laser and Laser-TIG Hybrid Welding, Opt. Lasers Eng., 2010, 48(4), p 512-517

X. Sun, E.V. Stephens, M.A. Khaleel, H. Shao, and M. Kimchi, Resistance Spot Welding of Aluminum Alloy to Steel with Transition Material-From Process to Performance, Weld. J., 2004, 83, p 188s-195s

S. Satonaka, C. Iwamoto, R. Qui, and T. Fujioka, Trends and New Applications of Spot Welding for Aluminium Alloy Sheets, Weld. Int., 2006, 20(11), p 858-864

R. Qiu, C. Iwamoto, and S. Satonaka, Interfacial Microstructure and Strength of Steel/Al Alloy Joints Welded by RSW with Cover Plate, J. Mater. Process. Technol., 2009, 209(8), p 4186-4193

J.S. Kim, I.J. Kim, and Y.G. Kim, Optimization of Welding Current Waveform for Dissimilar Material with DP590 and Al5052 by Delta-Spot Welding Process, J. Mech. Sci. Technol., 2016, 30(6), p 2713-2721

W. Zhang, D. Sun, L. Hana, and Y. Li, Optimised Design of Electrode Morphology for Novel Dissimilar Resistance Spot Welding of Aluminium Alloy and Galvanised High Strength Steel, Mater. Des., 2015, 85, p 461-470

D. Sun, Y. Zhang, Y. Liu, G. Xiaoyan, and H. Li, Microstructures and Mechanical Properties of Resistance Spot Welded Joints of 16 Mn Steel and 6063-T6 Aluminum Alloy with Different Electrodes, Mater. Des., 2016, 109, p 596-608

L.Z. Cheng and Y.H. Zhang, Physical Chemistry, Shanghai Science & Technology Press, Shanghai, 2007, p 3

K. Bouché, F. Barbier, and A. Coulet, Intermetallic Compound Layer Growth Between Solid Iron and Molten Aluminium, Mater. Sci. Eng. A, 1998, 249(1-2), p 167-175

W. Zhang, D. Sun, L. Han et al., Characterization of Intermetallic Compounds in Dissimilar Material Resistance Spot Welded Joint of High Strength Steel and Aluminum Alloy, Trans. Iron Steel Inst. Jpn., 2011, 51(11), p 1870-1877

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China [Grant Number 51275204]. The authors would like to thank Changchun Automobile Industry Institute for the support of welding experiment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Che, Y., Wang, L., Sun, D. et al. Microstructures and Mechanical Properties of Resistance Spot-Welded Steel/Aluminum Alloy Joints with Process Tapes. J. of Materi Eng and Perform 27, 5532–5544 (2018). https://doi.org/10.1007/s11665-018-3595-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3595-0