Abstract

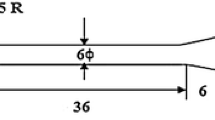

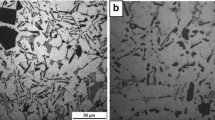

This study aims to evaluate the effects of prolonged thermal exposure on both microstructural evolution and mechanical properties of the EN AW-4032 T6 piston alloy. For the purpose, the experimental activities have been carried out on samples machined from forged and heat-treated automotive pistons. The effects of overaging have been investigated in the temperature range of 140-290 °C, firstly by evaluating the time-temperature-hardness curves and then by carrying out room-temperature tensile tests on overaged samples. The material softening was substantial and extremely rapid when the soaking temperature exceeded 250 °C. During overaging, both the tensile strength and the residual hardness considerably decreased, and a relationship between these parameters has been established. The alloy behavior in the plastic field has been modeled according to the Hollomon’s equation, showing that both the strain hardening exponent and the strength coefficient are a function of the residual hardness. The results were finally related to the corresponding microstructural changes: OM and FEG-SEM metallographic and fractographic analyses on overaged samples gave evidence of coarsened precipitates along the grain boundaries.

Similar content being viewed by others

References

L.F. Mondolfo, Aluminium Alloys: Structure and Properties, Butterwort, London, 1976

Y. Cho, D. Joo, and C. Kim, The Effect of Alloy Addition on the High Temperature Properties of Over-aged Al-Si (CuNiMg) Cast Alloys, Mater. Sci. Forum., 2006, 521, p 461–466. doi:10.4028/www.scientific.net/MSF.519-521.461

Y.H. Cho, Y.-R. Im, S.-W. Kwon, and H.C. Lee, The Effect of Alloying Elements on the Microstructure and Mechanical Properties of Al-12Si Cast Alloys, Mater. Sci. Forum., 2003, 426-432, p 339–344. doi:10.4028/www.scientific.net/MSF.426-432.339

D. Buono, E. Iarrobino, and A. Senatore, Optical Piston Temperature Measurement in an Internal Combustion Engine, SAE Int. J. Engines., 2011, 4, p 482–497. doi:10.4271/2011-01-0407

E. Balducci, A. Morri, L. Ceschini, and A. Morri, Effect of Thermal Exposure on Mechanical Properties of EN AW-2618 and EN AW-4032 Piston Alloys, La Metall. Ital., 2016, 6, p 89–92

G. Cantore, M. Giacopini, R. Rosi, A. Strozzi, P. Pelloni, C. Forte, M. Achilluzzi, G.M. Bianchi, L. Ceschini, A. Morri, Validation of a Combined CFD/FEM Methodology for the Evaluation of Thermal Load Acting on Aluminum Alloy Pistons Through Hardness Measurements in Internal Combustion Engines, Metall. Sci. Technol. 2011, 29

G. Nicoletto, E. Riva, and A. Di Filippo, High Temperature Fatigue Behavior of Eutectic Al-Si-Alloys used for Piston Production, Procedia Eng., 2014, 74, p 157–160. doi:10.1016/j.proeng.2014.06.241

H. Yamagata, The Science and Technology of Materials in Automotive Engines, Woodhead Publishing Limited, Cambridge, 2005

R. Konecna, G. Nicoletto, L. Kunz, and E. Riva, The Role of Elevated Temperature Exposure on Structural Evolution and Fatigue Strength of Eutectic AlSi12 Alloys, Int. J. Fatigue, 2015, 83, p 24–35. doi:10.1016/j.ijfatigue.2015.05.007

M. Rogante, V.T. Lebedev, F. Nicolaie, E. Retfalvi, and L. Rosta, SANS Study of the Precipitates Microstructural Evolution in Al 4032 Car Engine Pistons, Phys. B Condens. Matter, 2005, 358, p 224–231. doi:10.1016/j.physb.2005.01.240

L. Ceschini, A. Morri, A. Morri, and M. Di Sabatino, Effect of Thermal Exposure on the Residual Hardness and Tensile Properties of the EN AW-2618A Piston Alloy, Mater. Sci. Eng. A, 2015, 639, p 288–297. doi:10.1016/j.msea.2015.04.080

MAHLE GmbH, Pistons and Engine Testing, 2012. doi:10.1017/CBO9781107415324.004

E. Alonso, T.M. Lee, C. Bjelkengren, R. Roth, and R.E. Kirchain, Evaluating the Potential for Secondary Mass Savings in Vehicle Lightweighting, Environ. Sci. Technol., 2012, 46, p 2893–2901. doi:10.1021/es202938m

T. Luedeke and M. Vielhaber, Holistic Approach for Secondary Weight Improvements, Procedia CIRP., 2014, 21, p 218–223. doi:10.1016/j.procir.2014.03.139

G. Biroli, G. Caglioti, L. Martini, and G. Riontino, Precipitation Kinetics of AA4032 and AA6082: A Comparison Based on DSC and TEM, Scr. Mater., 1998, 39, p 197–203. doi:10.1016/S1359-6462(98)00140-7

F. Stadler, H. Antrekowitsch, W. Fragner, H. Kaufmann, E.R. Pinatel, and P.J. Uggowitzer, The Effect of Main Alloying Elements on the Physical Properties of Al-Si Foundry Alloys, Mater. Sci. Eng. A., 2013, 560, p 481–491. doi:10.1016/j.msea.2012.09.093

P. Krishnankutty, A. Kanjirathinkal, M.A. Joseph, and M. Ravi, Effect of Aging Time on Mechanical Properties and Wear Characteristics of Near Eutectic Al – Si – Cu – Mg – Ni Piston Alloy, Trans. Indian Inst. Met., 2015, 68, p 25–30. doi:10.1007/s12666-015-0584-y

F. Stadler, H. Antrekowitsch, W. Fragner, H. Kaufmann, and P.J. Uggowitzer, Effect of Main Alloying Elements on Strength of Al-Si Foundry Alloys at Elevated Temperatures, Int. J. Cast Met. Res., 2012, doi:10.1179/1743133612Y.0000000004

F. Stadler, H. Antrekowitsch, W. Fragner, H. Kaufmann, and P.J. Uggowitzer, The Effect of Ni on the High-Temperature Strength of Al-Si Cast Alloys, Mater. Sci. Forum., 2011, 690, p 274–277. doi:10.4028/www.scientific.net/MSF.690.274

Z. Asghar, G. Requena, H.P. Degischer, and P. Cloetens, Three-Dimensional Study of Ni Aluminides in an AlSi12 Alloy by Means of Light Optical and Synchrotron Microtomography, Acta Mater., 2009, 57, p 4125–4132. doi:10.1016/j.actamat.2009.05.010

J.H. Hollomon, Tensile Deformation, Trans. AIME., 1945, 162, p 268–290

G.E. Dieter, Mechanical Metallurgy, McGraw-Hil, New York, 1986

R.E. Reed-Hill, Physical Metallurgy Principles, D. Van Nostran Company, Litton Edu, 1973

R. Konečná, G. Nicoletto, L. Kunz, and M. Svoboda, a Bača, Fatigue Strength Degradation of AlSi12CuNiMg Alloy Due to High Temperature Exposure: A Structural Investigation, Procedia Eng., 2014, 74, p 43–46. doi:10.1016/j.proeng.2014.06.221

F. Novy, M. Janecek, and R. Král, Microstructure Changes in a 2618 Aluminium Alloy During Ageing and Creep, J. Alloy. Compd., 2009, 487, p 146–151

Acknowledgments

The authors gratefully acknowledge the National Council of Research (CNR), Dr. Boromei and Dr. Tarterini for their technical support for SEM-FEG investigations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balducci, E., Ceschini, L., Morri, A. et al. EN AW-4032 T6 Piston Alloy After High-Temperature Exposure: Residual Strength and Microstructural Features. J. of Materi Eng and Perform 26, 3802–3812 (2017). https://doi.org/10.1007/s11665-017-2835-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2835-z