Abstract

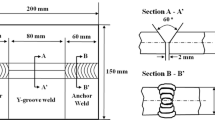

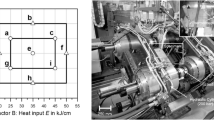

Cold cracking susceptibility of the newly developed 9Cr2WVTa steel plate welded with the corresponding gas tungsten arc welding wire has been evaluated using the implant test and the Y-groove cracking test. Measurement of diffusible hydrogen content shows that the welding wire is ultra-low welding consumables (0.40 mL/100 g). Results of the implant test show that the fracture critical stress without pre-heating is only 300 MPa and increases up to the yield strength with pre-heating to 150 °C. The fracture critical stress under high heat input decreases to 250 MPa owing to the formation of quenched microstructure. Fractographies show ductile dimple fracture under higher loads and quasi-cleavage fracture under lower loads. Results of Y-groove cracking tests show that the minimum pre-heating temperature is 150 °C and the maximum transverse residual stress is located at the root of the weld metal. Therefore, the heat input should be chosen in a proper range and the pre-heating temperature is no less than 150 °C.

Similar content being viewed by others

References

D. Gorse, T. Auger, J.B. Vogt, I. Serre, A. Weisenburger, A. Gessi, P. Agostini, C. Fazio, A. Hojna, F. Di Gabriele, J. Van Den Bosch, G. Coen, A. Almazouzi, and M. Serrano, Influence of liquid lead and lead-bismuth eutectic on tensile, fatigue and creep properties of ferritic/martensitic and austenitic steels for transmutation systems, J. Nucl. Mater., 2011, 415(3), p 284–292

S. Albert, M.V. Ramasubbu, M.S.S. Raj, and A. Bhaduri, Hydrogen-assisted cracking susceptibility of modified 9Cr-1 Mo steel and its weld metal, Weld World, 2011, 55(7–8), p 66–74

J. Vanaja, K. Laha, R. Mythili, K.S. Chandravathi, S. Saroja, and M.D. Mathew, Creep deformation and rupture behaviour of 9Cr-1W-0.2V-0.06Ta reduced activation ferritic-martensitic steel, Mater. Sci. Eng. A, 2012, 533, p 17–25

J. Wang, S. Lu, W. Dong, D. Li, and L. Rong, Microstructural evolution and mechanical properties of heat affected zones for 9Cr2WVTa steels with different carbon contents, Mater. Des., 2014, 64, p 550–558

J. Wang, S. Lu, L. Rong, and D. Li, Thermal cycling, microstructure and mechanical properties of 9Cr2WVTa steel welds, J. Mater. Process. Technol., 2015, 222, p 434–443

P. Hua, S. Moronov, C.Z. Nie, Y.S. Sato, H. Kokawa, S.H.C. Park, and S. Hirano, Microstructure and properties in friction stir weld of 12Cr steel, Sci. Technol. Weld. Join., 2014, 19(1), p 76–81 (English)

H.-J. Yi, Y.-J. Lee, J.-Y. Kim, and S.-S. Kang, Effect of microstructure and chemical composition on cold crack susceptibility of high-strength weld metal, J. Mech. Sci. Technol., 2011, 25(9), p 2185–2193

S. Manimozhi, S. Suresh, and V. Muthupandi, HAZ hydrogen cracking of 9Cr-0.5 Mo-1.7 W steels, Int. J. Adv. Manuf. Technol., 2010, 51(1-4), p 217–223

J. Wu, Study on microstructure and property of the welding joint of T92 steel tube. Shandong University, 2008 (in chinese)

J. Zhao, M. Chi, J. Li, G. Wang, P. Zhu, J. Zhang, and J. Zhao, Research on the cold crack sensitivity of P92 steel and its welding material, Electr. Equip., 2007, 8(2), p 45–49 (in chinese)

Hui X. Study of weldability and impact test for butt welds of domestic F92, heat resistant steel for boiler. Shanghai Jiao Tong University, 2008 (in chinese)

T. Kasuya and N. Yurioka, Determination of necessary preheat temperature to avoid cold cracking under varying ambient temperature, ISIJ Int., 1995, 35(10), p 1183–1189

G.M. Reddy, T. Mohandas, and D. Sarma, Cold cracking studies on low alloy steel weldments: effect of filler metal composition, Sci. Technol. Weld. Join., 2003, 8(6), p 407–414

J. Goldak, A. Chakravarti, and M. Bibby, A new finite element model for welding heat sources, Metall. Trans. B, 1984, 15(2), p 299–305

D. Deng and H. Murakawa, Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements, Comp. Mater. Sci., 2006, 37(3), p 269–277

D. Radaj, Welding residual stresses and distortion calculation and measurement-DVS, Verlag, 2003, ISBN 3-87155-791-9

H. Kim and B. Kang, Effect of microstructural variation on weld metal cold cracking of HSLA-100 steel, ISIJ Int., 2003, 43(5), p 706–713

Y. Huang, X. Chen, Z. Shen, B. Madigan, L. Yucheng, and J. Zhou, Measurement and analysis of SHCCT diagram for CLAM steel, J. Nucl. Mater., 2013, 432(1-3), p 460–465

B. Alexandrov, K. Theis, M. Streitenberger, H. Herold, and I. Martinek, Cold cracking in weldments of steel S 690 QT, Weld World, 2005, 49(5–6), p 64–73

Q. Gao, Y. Liu, X. Di, Z. Dong, and Z. Yan, The isochronal δ→γ transformation of high Cr ferritic heat-resistant steel during cooling, J. Mater. Sci., 2011, 46(21), p 6910–6915

X. Chen, Y. Huang, Z. Shen, J. Chen, Y. Lei, and J. Zhou, Effect of thermal cycle on microstructure and mechanical properties of CLAM steel weld CGHAZ, Sci. Technol. Weld. Join., 2013, 18(4), p 272–278

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 91226204) and the Chinese Academy of Science Strategic Pilot Project (The future of advanced nuclear energy-ADS evolution system) under Grant NO: XDA03010304. The authors acknowledge the valuable discussions with Dr. Xiangjun Chen in IMR, CAS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Lu, S., Li, Y. et al. Cold Cracking Sensitivity of a Newly Developed 9Cr2WVTa Steel. J. of Materi Eng and Perform 26, 258–267 (2017). https://doi.org/10.1007/s11665-016-2432-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2432-6