Abstract

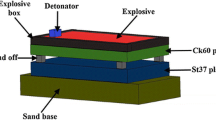

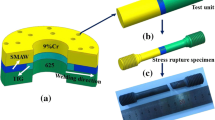

This study explores the effects of heat treatment on the microstructure and mechanical properties of explosively welded Ck60 steel/St37 steel. The objective is to find an economical way for manufacturing bimetallic plates that can be used in the rolling stand of hot rolling mill units. The explosive ratio and stand-off distance are set at 1.7 and 1.5t (t = flyer thickness), respectively. Since explosive welding is accompanied by such undesirable metallurgical effects as remarkable hardening, severe plastic deformation, and even formation of local melted zones near the interface, heat treatment is required to overcome or alleviate these adverse effects. For this purpose, the composites are subjected to heat treatment in a temperature range of 600-700 °C at a rate of 90 °C/h for 1 h. Results demonstrate well-bonded composite plates with a wavy interface. In the as-welded case, vortex zones are formed along the interface; however, they are transformed into fine grains upon heat treatment. Microhardness is also observed to be maximum near the interface in the welded case before it decreases with increasing temperature. Shear strength is the highest in the as-welded specimen, which later decreases as a result of heat treatment. Moreover, the energy absorbed by the heat-treated specimens is observed to increase with increasing temperature so that the lowest value of absorbed energy belongs to the as-welded specimen. Finally, fractography is carried out using the scanning electron microscope to examine the specimens subjected to shear and impact tests. As a result of heat treatment, fracture surfaces exhibit dimpled ruptures and fail in the mixed mode, while failure in the as-welded specimens predominantly occurs in the brittle mode.

Similar content being viewed by others

References

N. Zhang, W. Wang, X. Cao, and J. Wu, The Effect of Annealing on the Interface Microstructure and Mechanical Characteristics of AZ31B/AA6061 Composite Plates Fabricated by Explosive Welding, Mater. Des., 2015, 65, p 1100–1109

M. Acarer, B. Gülenç, and F. Findik, The Influence of Some Factors on Steel/Steel Bonding Quality on Their Characteristics of Explosive Welding Joints, J. Mater. Sci., 2004, 39, p 6457–6466

M. Sedighi and M. Honarpisheh, Experimental Study of Through-Depth Residual Stress in Explosive Welded Al-Cu-Al multilayer, Mater. Des., 2012, 37, p 577–581

M. Honarpisheh, M. Asemabadi, and M. Sedighi, Investigation of Annealing Treatment on the Interfacial Properties of Explosive-Welded Al/Cu/Al Multilayer, Mater. Des., 2012, 37, p 122–127

Z. Dhib, N. Guermazi, M. Gaspérini, and N. Haddar, Cladding of Low-Carbon Steel to Austenitic Stainless Steel by Hot-Roll Bonding: Microstructure and Mechanical Properties Before and After Welding, Mater. Sci. Eng. A, 2016, 656, p 130–141

M. Gloc, M. Wachowski, T. Plocinski, and K.J. Kurzydlowski, Microstructural and Microanalysis Investigations of Bond Titanium Grade1/Low Alloy Steel st52-3N Obtained by Explosive Welding, J. Alloys Compd., 2016, 671, p 446–451

I. Tatsukawa and A. Oda, Some Metallurgical Observations on Heating of Explosive Austenitic Stainless Clad Steel, Trans. Jpn. Weld. Soc., 1972, 3, p 48–58

D.V. Lazurenko, I.A. Bataev, V.I. Mali, A.A. Bataev, I.N. Maliutina, V.S. Lozhkin, M.A. Esikov, and A.M.J. Jorge, Explosively Welded Multilayer Ti-Al Composites: Structure and Transformation During Heat Treatment, Mater. Des., 2016, 102, p 122–130

C. Borchers, M. Lenz, M. Deutges, H. Klein, F. Gärtner, M. Hammerschmidt, and H. Kreye, Microstructure and Mechanical Properties of Medium-Carbon Steel Bonded on Low-Carbon Steel by Explosive Welding, Mater. Des., 2016, 89, p 369–376

F. Findik, R. Yilmaz, and T. Somyurek, The Effects of Heat Treatment on the Microstructure and Microhardness of Explosive Welding, Sci. Res. Essays, 2011, 6, p 4141–4151

Y. Morizono, M. Nishida, A. Chiba, and T. Yamamuro, Effect of Heat Treatment on Formation of Columnar Ferrite Structure in Explosively Welded Titanium/Hypoeutectoid Steel Joints, Mater. Sci. Forum, 2004, 465–466, p 373–378

M. Yazdani, M.R. Toroghinejad, and S.M. Hashemi, Investigation of Microstructure and Mechanical Properties of St37 steel-Ck60 Steel Joints by Explosive Cladding, J. Mater. Eng. Perform., 2015, 24, p 4032–4043

R. Kaçar and M. Acarer, Microstructure-Property Relationship in Explosively Welded Duplex Stainless Steel-Steel, Mater. Sci. Eng., A, 2003, 363, p 290–296

NC 501 General Specification, Explosion Bonded Clad Metals, Dynamic Materials Corporation (DMC), USA, December 1999

A.S. Bahrani, T.J. Black, and B. Crossland, The Mechanics of Wave Formation in Explosive Welding, Proc. R. Soc. Lond. Ser. A Math. Phys. Sci., 1967, 296, p 123–136

Y. Kaya and N. Kahraman, An Investigation Into the Explosive Welding/Cladding of Grade A Ship Steel/AISI, 316L Austenitic Stainless Steel, Mater. Des., 2013, 52, p 367–372

S.H. Ghaderi, A. Mori, and K. Hokamoto, Analysis of Explosively Welded Aluminum-AZ31 Magnesium Alloy Joints, Mater. Trans., 2008, 49, p 1142–1147

P. Manikandan, K. Hokamoto, A.A. Deribas, K. Raghukandan, and R. Tomoshige, Explosive Welding of Titanium/Stainless Steel by Controlling Energetic Conditions, Mater. Trans., 2006, 47, p 2049–2055

I.A. Bataev, A.A. Bataev, V.I. Mali, V.G. Burov, and E.A. Prikhod’ko, Formation and Structure of Vortex Zones Arising Upon Explosion Welding of Carbon Steels, Phys. Met. Metallogr., 2012, 113, p 233–240

A. Kurek, M. Wachowski, A. Niesłony, T. Płocinski, and K.J. Kurzydłowski, Fatigue Tests and Metallographic of Explosively Cladded Steel-Titanium Bimetal, Arch. Metall. Mater., 2014, 59, p 1565–1570

S.A.A. Akbari Mousavi and P. Farhadi Sartangi, Experimental Investigation of Explosive Welding of cp-Titanium/AISI, 304 Stainless Steel, Mater. Des., 2009, 30, p 459–468

M.H. Bina, F. Dehghani, and M. Salimi, Effect of Heat Treatment on Bonding Interface in Explosive Welded Copper/Stainless Steel, Mater. Des., 2013, 45, p 504–509

H.R. Zareie Rajani and S.A.A. Akbari Mousavi, The Effect of Explosive Welding Parameters on Metallurgical and Mechanical Interfacial Features of Inconel 625/Plain Carbon Steel Bimetal Plate, Mater. Sci. Eng. A, 2012, 556, p 454–464

N. Venkateswara Rao, G.M. Reddy, and S. Nagarjuna, Weld Overlay Cladding of High Strength Low Alloy Steel with Austenitic Stainless Steel—Structure and Properties, Mater. Des., 2011, 32, p 2496–2506

H. Jiang, X. Yan, J. Liu, and X. Duan, Effect of Heat Treatment on Microstructure and Mechanical Property of Ti-Steel Explosive-Rolling Clad Plate, Trans. Nonferrous Met. Soc. China, 2014, 24, p 697–704

N. Venkateswara Rao, D.S. Sarma, S. Nagarjuna, and G.M. Reddy, Influence of Hot Rolling and Heat Treatment on Structure and Properties of HSLA Steel Explosively Clad with Austenitic Stainless Steel, Mater. Sci Technol., 2009, 25, p 1387–1396

S.D. Norris, The Degradation of Dissimilar Explosively Welded Joints Due to Thermal Ageing, Int. J. Press. Vessels Pip., 1998, 75, p 735–748

M. Acarer, B. Gülenç, and F. Findik, Investigation of Explosive Welding Parameters and Their Effects on Microhardness and Shear Strength, Mater. Des., 2003, 24, p 659–664

R. Kacar and M. Acarer, An Investigation on the Explosive Cladding of 316L Stainless Steel-din-P355GH Steel, J. Mater. Process. Technol., 2004, 152, p 91–96

J.H. Chen, G.Z. Wang, and S.H. Hu, Mechanism of Detrimental Effects of Carbon Content on Cleavage Fracture Toughness of Low-Alloy Steel, Metall. Mater. Trans. A, 2001, 32, p 1081–1091

F.B. Pickering, Structure-Property Relationships in Steels, Constitution and Properties of Steels, F.B. Pickering, Ed., VCH, Weinheim, 1992,

B.H. Tao, Q. Li, Y.H. Zhang, T.C. Zhang, and Y. Liu, Effects of Post-Weld Heat Treatment on Fracture Toughness of Linear Friction Welded Joint for Dissimilar Titanium Alloys, Mater. Sci. Eng. A, 2015, 634, p 141–146

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yazdani, M., Toroghinejad, M.R. & Hashemi, S.M. Effects of Heat Treatment on Interface Microstructure and Mechanical Properties of Explosively Welded Ck60/St37 Plates. J. of Materi Eng and Perform 25, 5330–5342 (2016). https://doi.org/10.1007/s11665-016-2399-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2399-3