Abstract

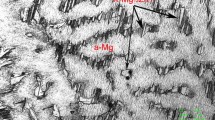

The wear properties of Mg97Zn1Y2 alloy were investigated using the pin-on-disk wear machine within a load range of 20-380 N and a sliding speed range of 0.2-4.0 m/s. Analysis of worn surfaces using scanning electron microscope and energy-dispersive x-ray spectrometer revealed that wear mechanisms including abrasion + oxidation, delamination accompanied by heavy surface oxidation and delamination operated in mild wear regime, while wear mechanisms such as severe plastic deformation, severe plastic deformation accompanied by spallation of oxidation layer and surface melting prevailed in severe wear regime. The microstructural evolution and hardness change in subsurfaces were examined by optical microscopy and hardness tester. The transformation of surface material from the deformed into dynamic recrystallization (DRX) microstructure was observed before and after mild-to-severe transition. The reason for mild-to-severe wear transition was identified as the transformation of strain hardening to DRX softening in subsurface. Mg97Zn1Y2 alloy has a superior mild-to-severe wear transition resistance to AZ alloys because of its higher recrystallization temperature. A novel model for evaluating the critical surface temperature of mild-to-severe wear transition was established using DRX kinetics.

Similar content being viewed by others

References

Y. Kawamura, K. Hayashi, A. Inoue, and T. Masumoto, Rapidly Solidified Powder Metallurgy Mg97Zn1Y2 Alloys with Excellent Tensile Yield Strength Above 600 MPa, Mater. Trans. JIM, 2001, 42, p 1172–1176

R.G. Li, H.J. Zhang, and G.Y. Fu, Microstructure and Mechanical Properties of Extruded Mg96Zn1Y3 Alloy, Mater. Charact., 2014, 98, p 107–112

H. Gao, K. Ikeda, T. Morikawa, K. Higashida, and H. Nakashima, Analysis of Kink Boundaries in Deformed Synchronized Long-Period Stacking Ordered Magnesium Alloys, Mater. Lett., 2015, 146, p 30–33

Y. Mine, H. Yoshimura, M. Matsuda, K. Takashima, and Y. Kawamura, Microfracture Behaviour of Extruded Mg-Zn-Y Alloys Containing Long-Period Stacking Ordered Structure at Room and Elevated Temperatures, Mater. Sci. Eng. A, 2013, 570, p 63–69

M. Matsuda, S. Ii, Y. Kawamura, Y. Ikuhara, and M. Nishida, Interaction Between Long Period Stacking Order Phase and Deformation Twin in Rapidly Solidified Mg97Zn1Y2 Alloy, Mater. Sci. Eng. A, 2004, 386, p 447–452

Y. Kawamura and M. Yamasaki, Formation and Mechanical Properties of Mg97Zn1RE2 Alloys with Long-Period Stacking Ordered Structure, Mater. Trans. JIM, 2007, 48, p 2986–2992

K. Hagihara, A. Kinoshita, Y. Fukusumi, M. Yamasaki, and Y. Kawamura, High-Temperature Compressive Deformation Behavior of Mg97Zn1Y2 Extruded Alloy Containing a Long-Period Stacking Ordered (LPSO) Phase, Mater. Sci. Eng. A, 2013, 560, p 71–79

H. Chen and A.T. Alpas, Sliding Wear Map for the Magnesium Alloy Mg-9Al-0.9Zn (AZ91), Wear, 2000, 246, p 106–116

C. Liang, X.X. Lv, and J. An, Correlation Between Friction-Induced Microstructural Evolution, Strain Hardening in Subsurface and Tribological Properties of AZ31 Magnesium Alloy, Wear, 2014, 312, p 29–39

T.F. Su, X. Han, Y.B. Wang, M.L. Yin, C. Liang, and J. An, An Investigation on Subsurface Microstructural Evolution and Mild to Severe Wear Transition in AZ51 Magnesium Alloy, Tribol. Trans., 2015, 58, p 549–559

A. Zafari, H.M. Ghasemi, and R. Mahmudi, Tribological Behavior of AZ91D Magnesium Alloy at Elevated Temperatures, Wear, 2012, 292–293, p 33–40

A.W. El-Morsy, Dry Sliding Wear Behavior of Hot Deformed Magnesium AZ61 Alloy as Influenced by the Sliding Conditions, Mater. Sci. Eng. A, 2008, 473, p 330–335

C. Taltavull, B. Torres, A.J. Lopez, and J. Rams, Dry Sliding Wear Behavior of AM60 Magnesium Alloy, Wear, 2013, 301, p 615–625

S. Ambu Selvan and S. Ramanathan, Dry Sliding Wear Behavior of Hot Extruded ZE41A Magnesium Alloy, Mater. Sci. Eng. A, 2010, 527, p 1815–1820

J. An, R.G. Li, Y. Lu, C.M. Chen, Y. Xu, X. Chen, and L.M. Wang, Dry Sliding Wear Behavior of Magnesium Alloys, Wear, 2008, 265, p 97–104

L.J. Cao, Y.J. Wu, L.M. Peng, Q.D. Wang, and W.J. Ding, Microstructure and Tribological Behavior of Mg-Gd-Zn-Zr Alloy with LPSO Structure, Trans. Nonferrous Met. Soc. China, 2014, 24, p 3785–3791

K. Hagihara, N. Yokotani, and Y. Umakoshi, Plastic Deformation Behavior of Mg12YZn with 18R Long-Period Stacking Ordered Structure, Intermetallics, 2010, 18, p 267–276

H.Y. Gao, K. Ikeda, T. Morikawa, K. Higashida, and H. Nakashima, Microstructure of Long-Period Stacking Ordered Phase of Mg-Zn-Y Alloy, Mater. Trans. JIM, 2013, 54, p 632–635

C. Liang, X. Han, T.F. Su, X.X. Lv, and J. An, Roles of Friction-Induced Strain Hardening and Recrystallization in Dry Sliding Wear of AZ31 Magnesium Alloy, Trans. Indian Inst. Met., 2015, 68, p 89–98

C. Liang, T.F. Su, Y.B. Wang, X. Han, M.L. Yin, and J. An, An Investigation on Transition Between Mild and Severe Wear in Mg-5Al-0.8Zn Magnesium Alloy Using Recrystallization Kinetics Modeling, J. Tribol., 2015, 137, p 031602-1-12

H. Somekawa, S. Meada, T. Hirayama, T. Mitsuoka, T. Inoue, and T. Mukai, Microstructural Evolution During Dry Wear Test in Magnesium and Mg-Y Alloy, Mater. Sci. Eng. A, 2013, 561, p 371–377

B. Yao, Z. Han, and K. Lu, Correlation Between Wear Resistance and Subsurface Recrystallization Structure in Copper, Wear, 2012, 294–295, p 438–445

H. Watanabe, T. Mukai, K. Ishikawa, and K. Higashi, High-Strain-Rate Superplasticity in an AZ91 Magnesium Alloy Processed by Ingot Metallurgy Route, Mater. Trans., 2002, 43, p 78–80

H. Watanabe, H. Somekawa, and K. Higashi, Fine-Grain Process by Equal Channel Angular Extrusion of Rapidly Quenched Bulk Mg-Y-Zn Alloy, J. Mater. Res., 2005, 20, p 93–101

X. Yang, Y. Okabe, H. Miura, and T. Sakai, Effect of Pass Strain and Temperature on Recrystallisation in Magnesium Alloy AZ31 After Interrupted Cold Deformation, J. Mater. Sci., 2012, 47, p 2823–2830

C. Sellars and W.M. Tegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14, p 1136–1138

Acknowledgments

The authors wish to express their gratitude for the support under the Project 985-Automotive Engineering of Jilin University, National Foundation of Doctoral Station (Grant No. 20110061110031) and Project 2016180 Supported by Graduate Innovation Fund of Jilin University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

An, J., Xuan, X.H., Zhao, J. et al. Dry Sliding Wear Behavior and Subsurface Microstructure Evolution of Mg97Zn1Y2 Alloy in a Wide Sliding Speed Range. J. of Materi Eng and Perform 25, 5363–5373 (2016). https://doi.org/10.1007/s11665-016-2381-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2381-0