Abstract

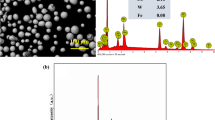

Al2O3 micro-powder was suspended in the basis electrolyte to form micro-arc oxidation (MAO) coatings on 6061 aluminum alloy by MAO. During the stage of micro-arc oxidation, Al2O3 micro-powder with negative surface charge was melted by the micro-arc around the anode and incorporated into the MAO coatings. With the continuous addition of Al2O3 micro-powder, the oxidation voltages rose up firstly and then decreased. The surface and cross-sectional morphologies showed that the size of micropores decreased and the MAO coatings surface got loosened following the variation in Al2O3 micro-powder concentration. As a consequence of the changing coating structure, the corrosion resistance of the coatings decreased apparently. The micro-hardness of the coatings increased firstly and then decreased, opposite to the trend of the average friction coefficient. It revealed the minimum average friction coefficient of MAO coatings and maximum adhesion between the coatings and substrate when 2.0 g/L Al2O3 micro-powder was added into electrolyte. There were visible cracks and peelings on the coating surface merely at 4.0 g/L after thermal shock tests. The x-ray diffraction results indicated that the addition of Al2O3 micro-powder had less effect on the phase composition of MAO coatings.

Similar content being viewed by others

References

V. Shoaei-Rad, M.R. Bayati, H.R. Zargar, J. Javadpour, and F. Golestani-Fard, In situ growth of ZrO2-Al2O3 nano-crystalline ceramic coatings via micro arc oxidation of aluminum substrates, Mater. Res. Bull., 2012, 47(6), p 1494–1499

A. Venugopal, R. Panda, S. Manwatkar, K. Sreekumar, L. Rama Krishna, and G. Sundararajan, Effect of micro arc oxidation treatment on localized corrosion behaviour of AA7075 aluminum alloy in 3.5% NaCl solution, Trans. Nonferrous Met. Soc. China, 2012, 22(3), p 700–710

J. Li, H. Cai, X. Xue, and B. Jiang, The outward-inward growth behavior of microarc oxidation coatings in phosphate and silicate solution, Mater. Lett., 2010, 64(19), p 2102–2104

L. Wen, Y. Wang, Y. Zhou, L. Guo, and J.H. Ouyang, Microstructure and corrosion resistance of modified 2024 Al alloy using surface mechanical attrition treatment combined with microarc oxidation process, Corros. Sci., 2011, 53(1), p 473–480

D.E. Lozano, R.D. Mercado-Solis, A.J. Perez, J. Talamantes, F. Morales, and M.A.L. Hernandez-Rodriguez, Tribological behaviour of cast hypereutectic Al-Si-Cu alloy subjected to sliding wear, Wear, 2013, 301(s1–4), p 434–443

G. Sabatini, L. Ceschini, C. Martini, J.A. Williams, and I.M. Hutchings, Improving sliding and abrasive wear behaviour of cast A356 and wrought AA7075 aluminium alloys by plasma electrolytic oxidation, Mater. Des., 2010, 31(2), p 816–828

D. Shen, G. Li, C. Guo, J. Zou, J. Cai, and D. He, Microstructure and corrosion behavior of micro-arc oxidation coating on 6061 aluminum alloy pre-treated by high-temperature oxidation, Appl. Surf. Sci., 2013, 287, p 451–456

L. Gorjan, G. Blugan, M. Boretius, S. De La Pierre, M. Ferraris, and V. Casalegno, Fracture behavior of soldered Al2O3 ceramic to A356 aluminum alloy and resistance of the joint to low temperatures exposure, Mater. Des., 2015, 88, p 889–896

Y.L. Song, X.Y. Sun, and Y.H. Liu, Effect of TiO2 nanoparticles on the microstructure and corrosion behavior of MAO coatings on magnesium alloy, Mater. Corros., 2012, 63(9), p 813–818

X. Li and B.L. Luan, Discovery of Al2O3 particles incorporation mechanism in plasma electrolytic oxidation of AM60B magnesium alloy, Mater. Lett., 2012, 86, p 88–90

P. Wang, X.Y. Guo, and X.L. Mao, Influences of vanadium doping on structure and performance of aluminum alloy micro-arc oxidation coating, Rare. Met. Mater. Eng., 2014, 43(7), p 1759–1763 ([in Chinese])

D. Shen, G. Li, C. Guo, J. Zou, J. Cai, and D. He, Microstructure and corrosion behavior of micro-arc oxidation coating on 6061 aluminum alloy pre-treated by high-temperature oxidation, Appl. Surf. Sci., 2013, 265, p 431–437

H.X. Li and R.G. Song, Effects of nano-additive TiO2 on performance of micro-arc oxidation coatings formed on 6063 aluminum alloy, Trans. Nonferrous Met. Soc. China, 2013, 23, p 406–412

Y. Zhong, L. Shi, M. Li, F. He, and X. He, Characterization and thermal shock behavior of composite ceramic coating doped with ZrO2 particles on TC4 by micro-arc oxidation, Appl. Surf. Sci., 2014, 311, p 158–163

Z. Jiang, X. Zeng, and Z. Yao, Preparation of micro-arc oxidation coatings on magnesium alloy and its thermal shock resistance property, Rare Met., 2006, 25(3), p 270–273

Acknowledgments

The present work was supported by the Scientific Research Starting Project (2015QHZ020) and Open Fund (X151515KCL16) of Sichuan Province University Key Laboratory of oil and gas field material, Southwest Petroleum University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, P., Wu, T., Xiao, Y.T. et al. Effect of Al2O3 Micro-powder Additives on the Properties of Micro-arc Oxidation Coatings Formed on 6061 Aluminum Alloy. J. of Materi Eng and Perform 25, 3972–3976 (2016). https://doi.org/10.1007/s11665-016-2255-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2255-5