Abstract

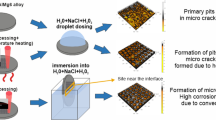

The article deals with the pretreatment technique for preparing the surface of aluminum alloy EN AW 5754 before thermal spray. The surface after different pretreatments, including degreasing with acetone, chemical etching with acidic and alkali solutions, grit-blasting, cathodic cleaning, and some combinations of these techniques, has been studied. The investigation of pre-treated surfaces covered the topographical study (using scanning electron microscopy, atomic force microscopy, and 3D profilometry), the chemical analysis by x-ray photoelectron spectroscopy, the evaluation of surface wettability (sessile drop method), and the assessment of surface free energy. Compared with all the techniques used in present work, the cathodic cleaning and its combination with grit-blasting provide the most preferable chemistry of the surface. Due to the absence of hydroxides at the surface and, possible, due to the diffusion of magnesium to the surface of substrate, the surface wettability and the surface free energy have been significantly improved. No direct correlation between the surface topography and the surface wettability has been established.

Similar content being viewed by others

References

J.R. Davis (ed.), Coating Structure, Properties, and Materials, Handbook of Thermal Spray Technology (ASM International, Materials Park, 2004), pp. 47–53

P.L. Fauchais, J.V.R. Heberlein, and M.I. Boulos, Thermal Spray Fundamentals: From Powder to Part, Springer, New York, 2004

C.C. Berndt and C.K. Lin, Measurement of Adhesion for Thermally Sprayed Materials, Adhesion Measurement of Films and Coatings, K.L. Mittal, Ed., VSP, Leiden, 1995, p 41–70

R.S.C. Paredes, S.C. Amico, and A.S.C.M. d’Oliveira, The Effect of Roughness and Pre-heating of the Substrate on the Morphology of Aluminium Coatings Deposited by Thermal Spraying, Surf. Coat. Technol., 2006, 200(9), p 3049–3055. doi:10.1016/j.surfcoat.2005.02.200

P. Białucki and S. Kozerski, Study of Adhesion of Different Plasma-Sprayed Coatings to Aluminium, Surf. Coat. Technol., 2006, 201(5), p 2061–2064. doi:10.1016/j.surfcoat.2006.04.043

L. Gu, X. Fan, Y. Zhao, B. Zou, Y. Wang, S. Zhao, and X. Cao, Influence of Ceramic Thickness on Residual Stress and Bonding Strength for Plasma Sprayed Duplex Thermal Barrier Coating on Aluminum Alloy, Surf. Coat. Technol., 2012, 206(21), p 4403–4410. doi:10.1016/j.surfcoat.2012.04.070

Y. Tan, L. He, X. Wang, X. Hong, and W. Wang, Tribological Properties and Wear Prediction Model of TiC Particles Reinforced Ni-base Alloy Composite Coatings, Trans. Nonferrous Met. Soc. China, 2014, 24(8), p 2566–2573. doi:10.1016/S1003-6326(14)63384-7

L. He, Y. Tan, H. Tan, C. Zhou, and L. Gao, Tribological Properties of Nanostructured Al2O3-40%TiO2 Multiphase Ceramic Particles Reinforced Ni-based Alloy Composite Coatings, Trans. Nonferrous Met. Soc. China, 2013, 23, p 2618–2627. doi:10.1016/S1003-6326(13)62776-4

L. He, Y. Tan, X. Wang, T. Xu, and X. Hong, Microstructure and Wear Properties of Al2O3-CeO2/Ni-base Alloy Composite Coatings on Aluminum Alloys by Plasma Spray, Appl. Surf. Sci., 2014, 314, p 760–767. doi:10.1016/j.apsusc.2014.07.047

L. He, Y. Tan, H. Tan, Y. Tu, and Z. Zhang, Microstructure and Tribological Properties of WC-CeO2/Ni-base Alloy Composite Coatings, Rare Met. Mater. Eng., 2014, 43(4), p 823–829. doi:10.1016/S1875-5372(14)60092-8

M.F. Morksa, Y. Tsunekawa, N.F. Fahim, and M. Okumiya, Microstructure and Friction Properties of Plasma Sprayed Al-Si Alloyed Cast Iron Coatings, Mater. Chem. Phys., 2006, 96(1), p 170–175. doi:10.1016/j.matchemphys.2005.07.002

K. Nakata and M. Ushio, Wear Resistance of Plasma Sprayed Al-Si Binary Alloy Coatings on A6063 Al Alloy Substrate, Surf. Coat. Technol., 2001, 142–144, p 277–282. doi:10.1016/S0257-8972(01)01088-X

K. Nakata and M. Ushio, Effect of Fe Content on Wear Resistance of Thermal-Sprayed Al-17Si-XFe Alloy Coating on A6063 Al Alloy Substrate, Surf. Coat. Technol., 2003, 169–170, p 443–446. doi:10.1016/S0257-8972(03)00187-7

O. Sarikaya, S. Anik, S. Aslanlar, S.C. Okumus, and E. Celik, Al-Si/B4C Composite Coatings on Al-Si Substrate by Plasma Spray Technique, Mater. Des., 2007, 28(9), p 2443–2449. doi:10.1016/j.matdes.2006.09.007

R.G. Song, C. Wang, Y. Jiang, H. Li, G. Lu, and Z.X. Wang, Microstructure and Properties of Al2O3/TiO2 Nanostructured Ceramic Composite Coatings Prepared by Plasma Spraying, J. Alloys Compd., 2012, 544, p 13-18. doi:10.1016/j.jallcom.2012.07.032

S. Uozato, K. Nakata, and M. Ushio, Evaluation of Ferrous Powder Thermal Spray Coatings on Diesel Engine Cylinder Bores, Surf. Coat. Technol., 2005, 200(7), p 2580–2586. doi:10.1016/j.surfcoat.2005.05.042

S. Brossard, P.R. Munroe, A.T.T. Tran, and M.M. Hyland, Study of the Splat Formation for Plasma Sprayed NiCr on Aluminum Substrate as a Function of Substrate Condition, Surf. Coat. Technol., 2010, 204(16–17), p 2647–2656. doi:10.1016/j.surfcoat.2010.02.013

A.T.T. Tran, M.M. Hyland, K. Shinoda, and S. Sampath, Influence of Substrate Surface Conditions on the Deposition and Spreading of Molten Droplets, Thin Solid Films, 2011, 519(8), p 2445–2456. doi:10.1016/j.tsf.2010.11.047

A.T.T. Tran, M.M. Hyland, K. Shinoda, and S. Sampath, Inhibition of Molten Droplet Deposition by Substrate Surface Hydroxides, Surf. Coat. Technol., 2011, 206(6), p 1283–1292. doi:10.1016/j.surfcoat.2011.08.041

Y. Danlos, S. Costil, H. Liao, and C. Coddet, Combining Effects of Ablation Laser and Laser Preheating on Metallic Substrates Before Thermal Spraying, Surf. Coat. Technol., 2008, 202(18), p 4531–4537. doi:10.1016/j.surfcoat.2008.04.038

Y. Danlos, S. Costil, H. Liao, and C. Coddet, Influence of Ti-6Al-4V and Al 2017 Substrate Morphology on Ni-Al Coating Adhesion—Impacts of Laser Treatments, Surf. Coat. Technol., 2001, 205(8–9), p 2702–2708. doi:10.1016/j.surfcoat.2010.08.147

P. Kruger, R. Knes, and J. Friedrich, Surface Cleaning by Plasma-Enhanced Desorption of Contaminants (PEDC), Surf. Coat. Technol., 1999, 112(1–3), p 240–244. doi:10.1016/S0257-8972(98)00777-4

N. Anagreh and A. Robaidi, Improvement in Adhesion Behavior of Aluminum Due to Surfaces Treatment with Arc Discharge, Jordan J. Mech. Ind. Eng., 2010, 4(2), p 330–339

G.W. Critchlow and D.M. Brewis, Review of Surface Pretreatments for Aluminium Alloys, Int. J. Adhes. Adhes., 1996, 16(4), p 255–275. doi:10.1016/S0143-7496(96)00014-0

M. Robotti, S. Dosta, M. Gardon, I.G. Cano, J.M. Guilemany, M. Kourasi, B. Mellor, and R. Wills, Enhancing the Performance of Common Electrode Materials by Means of Atmospheric Plasma Spray Coatings, J. Energy Storage, 2016, 5, p 127–133. doi:10.1016/j.est.2015.12.001

M. Winnicki, A. Małachowska, M. Rutkowska-Gorczyca, P. Sokołowski, A. Ambroziak, and L. Pawłowski, Characterization of Cermet Coatings Deposited by Low-Pressure Cold Spraying, Surf. Coat. Technol., 2015, 268, p 108–114. doi:10.1016/j.surfcoat.2014.12.070

M. Couto, S. Dosta, and J.M. Guilemany, Comparison of the Mechanical and Electrochemical Properties of WC-17 and 12Co Coatings onto Al7075-T6 Obtained by High Velocity Oxy-Fuel and Cold Gas Spraying, Surf. Coat. Technol., 2015, 268, p 180–189. doi:10.1016/j.surfcoat.2014.04.034

H. Long, T. Yefa, W. Xiaolong, X. Ting, and H. Xiang, Microstructure and Wear Properties of Al2O3-CeO2/Ni-base Alloy Composite Coatings on Aluminum Alloys by Plasma Spray, Appl. Surf. Sci., 2014, 314, p 760–767. doi:10.1016/j.apsusc.2014.07.047

B. Torres, M. Campo, M. Lieblich, and J. Rams, Oxy-Acetylene Flame Thermal Sprayed Coatings of Aluminium Matrix Composites Reinforced with MoSi2 Intermetallic Particles, Surf. Coat. Technol., 2013, 236, p 274–283. doi:10.1016/j.surfcoat.2013.10.001

L. Gu, X. Fan, Y. Zhao, B. Zou, Y. Wang, S. Zhao, and X. Cao, Influence of Ceramic Thickness on Residual Stress and Bonding Strength for Plasma Sprayed Duplex Thermal Barrier Coating on Aluminum Alloy, Surf. Coat. Technol., 2012, 206(21), p 4403–4410. doi:10.1016/j.surfcoat.2012.04.070

A. Naimi, H. Yousfi, and M. Trari, Microstructure and Corrosion Resistance of Molybdenum and Aluminum Coatings Thermally Sprayed on 7075-T6 Aluminum Alloy, Prot. Met. Phys. Chem. Surf., 2012, 48(5), p 557–562, http://link.springer.com/article/10.1134%2FS2070205112050061.

R.G. Song, C. Wang, Y. Jiang, H. Li, G. Lu, and Z.X. Wang, Microstructure and Properties of Al2O3/TiO2 Nanostructures Ceramic Composite Coatings Prepared by Plasma Spraying, J. Alloys Compd., 2012, 544, p 13–18. doi:10.1016/j.jallcom.2012.07.032

I. Tsangaraki-Kaplanoglou, S. Theohari, Th Dimogerontakis, Y.M. Wang, H.H.H. Kuo, and S. Kia, Effect of Alloy Types on the Anodizing Process of Aluminum, Surf. Coat. Technol., 2006, 200(8), p 2634–2641. doi:10.1016/j.surfcoat.2005.07.065

S.V. Oleynik, Yu.A. Kuzenkov, S.A. Karimova, and T.I. Tararaeva, Non-Chromate Conversion Coatings on A7075 Aluminum Alloy after Various Thermal Treatment, Prot. Met. Phys. Chem. Surf., 2011, 47(7), p 889–894, http://link.springer.com/article/10.1134%2FS2070205111070124

T. Aerts, I. Graeve, and H. Terryn, Anodizing of Aluminium under Applied Electrode Temperature: Process Evaluation and Elimination of Burning at High Current Densities, Surf. Coat. Technol., 2010, 204, p 2754–2760. doi:10.1016/j.surfcoat.2010.02.031

A. Bjorgum, F. Lapique, J. Walmsley, and K. Redford, Anodising as Pre-Treatment for Structural Bonding, Int. J. Adhes. Adhes., 2003, 23(5), p 401–412. doi:10.1016/S0143-7496(03)00071-X

S.S. Golru, M.M. Attar, and B. Ramezanzadeh, Effects of Different Surface Cleaning Procedures on the Superficial Morphology and the Adhesive Strength of Epoxy Coating on Aluminium Alloy 1050, Prog. Org. Coat., 2015, 87, p 52–60. doi:10.1016/j.porgcoat.2015.05.005

O. Lunder, B. Olsen, and K. Nisancioglu, Pre-treatment of AA6060 Aluminium Alloy for Adhesive Bonding, Int. J. Adhes. Adhes., 2002, 22(2), p 143–150. doi:10.1016/S0143-7496(01)00049-5

P. Erdogan, B. Yuksel, and Y. Birol, Effect of Chemical Etching on the Morphology of Anodic Aluminum Oxides in the Two-Step Anodization Process, Appl. Surf. Sci., 2012, 258(10), p 4544–4550. doi:10.1016/j.apsusc.2012.01.025

R. Lukauskaitė, A.V. Valiulis, and O. Černašėjus, Investigation of Cathodic Cleaning Processes of Aluminum Alloy, Solid State Phenom., 2015, 220–221, p 684–692

C.D. Wagner, W.M. Riggs, L.E. Davis, J.F. Moulder, and G.E. Muilenberg, Handbook of X-ray Photoelectron Spectroscopy, Perkin Elmer Corporation, St. Paul, 1978

NIST X-ray Photoelectron Spectroscopy Database on http://srdata.nist.gov/xps/. Accessed 14 Sept 2015

A. Baldan, Adhesion Phenomena in Bonded Joints, Int. J. Adhes. Adhes., 2012, 38, p 95–116. doi:10.1016/j.ijadhadh.2012.04.007

L. Mazzola, E. Bemporad, and F. Carassiti, An Easy Way to Measure Surface Free Energy by Drop Shape Analysis, Measurement, 2012, 45(3), p 317–324. doi:10.1016/j.measurement.2011.11.016

A. Rudawska and E. Jacniacka, Analysis for Determining Surface Free Energy Uncertainty by the Owen-Wendt Method, Int. J. Adhes. Adhes., 2009, 29(4), p 451–457. doi:10.1016/j.ijadhadh.2008.09.008

Y. Tan and M. Guo, Using Surface Free Energy Method to Study the Cohesion and Adhesion of Asphalt Mastic, Constr. Build. Mater., 2013, 47, p 254–260. doi:10.1016/j.conbuildmat.2013.05.067

W. Pinc, S. Geng, M. O’Keefe, W. Fahrenholtz, and T. O’Keefe, Effects of Acid and Alkaline Based Surface Preparations on Spray Deposited Cerium Based Conversion Coatings on Al 2024-T3, Appl. Surf. Sci., 2009, 255(7), p 4061–4065. doi:10.1016/j.apsusc.2008.10.110

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lukauskaitė, R., Valiulis, A.V., Černašėjus, O. et al. Preparing Al-Mg Substrate for Thermal Spraying: Evaluation of Surface State After Different Pretreatments. J. of Materi Eng and Perform 25, 3493–3505 (2016). https://doi.org/10.1007/s11665-016-2153-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2153-x