Abstract

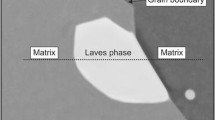

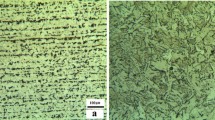

A dissimilar joint of 25Cr-35Ni/30Cr-48Ni (HP/HV) heat-resistant steels was evaluated. The investigations indicated that the as-cast HP alloy contained M7C3, M23C6, and NbC carbides and HV alloy with 5 wt.% tungsten, contained M23C6 and M6C carbides embedded in an austenitic matrix. After 8 years of ex-service aging at 1050 °C, the ductility of HP/HV reformer tubes was decreased dramatically, and thus, the repair welding of the aged HP/HV dissimilar joint was at a risk. In order to repair the aged reformer tubes and increase weldability properties, a new partial solution annealing treatment was designed. Mechanical testing results showed that partial solution annealing at 1200 °C for 6 h increased the elongation and toughness of the aged HP and HV alloys drastically. Also, a mechanism for constitutional liquation cracking in the heat-affected zones (HAZ) of the HP/HV dissimilar joint was proposed. In the HAZ of the aged HP/HV welded joint, the cracks around the locally melted carbides were initiated and propagated during carbides solidification at the cooling cycle of welding associated with the decrease in the ductility of the aged HP and HV alloys. In addition, Varestraint weldability test showed that the susceptibility to hot cracking was decreased with partial solution annealing.

Similar content being viewed by others

References

J.R. Davis, Ed., Heat-Resistant Materials: ASM Specialty Handbook, ASM International, Materials Park, 1999, p 200–205

J.R. Davis, Ed., Alloy Digest Sourcebook: Stainless Steels, ASM International, Materials Park, 2000, p 455–458

J. Laigo, F. Christien, R. Le Gall, F. Tancret, and J. Furtado, SEM, EDS, EPMA-WDS and EBSD Characterization of Carbides in HP Type Heat Resistant Alloys, Mater. Charact., 2008, 59, p 1580–1586

A.F. Ribeiro, L.H. de Almeida, D.S. dos Santos, D. Fruchart, and G.S. Bobrovnitchii, Microstructural Modifications Induced by Hydrogen in a Heat Resistant Steel Type HP-45 with Nb and Ti Additions, J. Alloys. Compd., 2003, 356–357, p 693–696

L.H. de Almeida, A.F. Ribeiro, and I. Le May, Microstructural Characterization of Modified 25Cr-35Ni Centrifugally Cast Steel Furnace Tubes, Mater. Charact., 2002, 49, p 219–229

E. Kenik, Structure and Phase Stability in a Cast Modified-HP Austenite After Long-Term Ageing, Scr. Mater., 2003, 49, p 117–122

M. Mostafaei, M. Shamanian, H. Purmohamad, M. Amini, and A. Saatchi, Microstructural Degradation of Two Cast Heat Resistant Reformer Tubes After Long Term Service Exposure, Eng. Fail. Anal., 2011, 18, p 164–171

S. Shi and J.C. Lippold, Microstructure Evolution During Service Exposure of Two Cast, Heat-Resisting Stainless Steels—HP-Nb Modified and 20-32Nb, Mater. Charact., 2008, 59, p 1029–1040

A.R. Andrade, C. Bolfarini, L.A.M. Ferreira, C.D. Souza Filho, and L.H.C. Bonazzi, Titanium Micro Addition in a Centrifugally Cast HPNb Alloy: High Temperature Mechanical Properties, Mater. Sci. Eng., A, 2015, 636, p 48–52

L. Bonaccorsi, E. Guglielmino, R. Pino, C. Servetto, and A. Sili, Damage Analysis in Fe-Cr-Ni Centrifugally Cast Alloy Tubes for Reforming Furnaces, Eng. Fail. Anal., 2014, 36, p 65–74

D. Klarstorm, Heat Treatment/Property Relationships for Solid-Solution Strengthened Heat Resistant Alloys, Proc. First Int. Conf. Heat-Resist Mater., K. Natesan, D.J. Tillack, Eds., (Wisconsin), ASM International, 1991.

S. Borjali, S.R. Allahkaram, and H. Khosravi, Effects of Working Temperature and Carbon Diffusion on the Microstructure of High Pressure Heat-Resistant Stainless Steel Tubes Used in Pyrolysis Furnaces During Service Condition, Mater. Design., 2012, 34, p 65–74

J.R. Davis, Ed., Nickel, Cobalt, and Their Alloys: ASM Specialty Handbook, ASM International, Materials Park, 2000, p 66–67

C.M. Schillmoller, Alloys for Ethylene Cracking Furnace Tubes, Proc. First Int. Conf. Heat-Resist Mater., K. Natesan, D.J. Tillack, Eds., (Wisconsin), ASM International, 1991.

I. Aydin, H.E. Buehler, and A. Rahmel, Precipitation in the Heat Resistant Nickel-Base Cast Alloy G-NiCr 28W and G-NiCr 50 Nb, Arch. Eisenhuettenwesen., 1983, 54, p 461–466 ((in German))

I.A. Sustaita-Torres, S. Haro-Rodríguez, M.P. Guerrero-Mata, M. de la Garza, E. Valdés, F. Deschaux-Beaume, and R. Colás, Aging of a Cast 35Cr-45Ni Heat Resistant Alloy, Mater. Chem. Phys., 2012, 133, p 1018–1023

T. Branza, F. Deschaux-Beaume, G. Sierra, and P. Lours, Study and Prevention of Cracking During Weld-Repair of Heat-Resistant Cast Steels, J. Mater. Process. Tech., 2009, 209, p 536–547

S.R. Allahkaram, S. Borjali, and H. Khosravi, Investigation of Weldability and Property Changes Of High Pressure Heat-Resistant Cast Stainless Steel Tubes Used in Pyrolysis Furnaces After a Five-Year Service, Mater. Design., 2012, 33, p 476–484

ASTM E8, E8M-15, Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, 2015

ANSI/AWS B 4.0., Standard Methods for Mechanical Testing of Welds, American Welding Society, Miami, 2007

C.D. Lundin and W.F. Savage, Application of the Varestraint Technique to the Study of Weldability, Weld. J., 1966, 45, p 497–503

W.F. Savage and C.D. Lundin, The Varestraint Test, Weld. J., 1965, 44, p 433–442

J.N. DuPont, J.C. Lippold, and S.D. Kiser, Welding Metallurgy and Weldability of Nickel-base Alloys, Wiley, Hoboken, 2009, p 217–223

M. Bergström, The Eta-Carbides in the Quaternary System Fe-W-C-Cr at 1250°C, Mater. Sci. Eng., 1977, 27, p 271–286

http://www.schmidt-clemens.com/company/infos-downloads/brochures.html.

A. Duchosal, F. Deschaux-Beaume, C. Bordreuil, G. Fras, and P. Lours, Method for Predicting Risk of Cracking During Weld Repair of Heat Resistant Cast Steels, Sci. Technol. Weld. Join., 2008, 13, p 126–135

R. Dehmolaei, M. Shamanian, and A. Kermanpur, Improving Weldability of Aged 25Cr-35Ni Heat Resistant Steel/Alloy 800 Dissimilar Welds, Sci. Technol. Weld. Join., 2007, 12, p 586–592

R.S. Haro, L.D. López, T.A. Velasco, and B.R. Viramontes, Microstructural Factors That Determine the Weldability of a High Cr-High Si HK 40 Alloy, Mater. Chem. Phys., 2000, 66, p 90–96

K. Shinozaki, H. Kuroki, Y. Nakao, K. Nishimoto, M. Inui, and M. Takahashi, Deterioration of Weldability of Long-Term Aged HP Heat-Resistant Cast Steel Containing Nb, Mo, and W, Weld. Int., 1999, 13, p 39–48

A. Inoue, S. Arakawa, and T. Masumoto, Effect of Alloying Elements on Defect Structure and Hardness of M23C6 Type Carbides, T. Jpn. I. Met., 1979, 20, p 585–592

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mostafaei, M., Shamanian, M., Purmohamad, H. et al. Increasing Weldability of Service-Aged Reformer Tubes by Partial Solution Annealing. J. of Materi Eng and Perform 25, 1291–1303 (2016). https://doi.org/10.1007/s11665-016-1973-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1973-z