Abstract

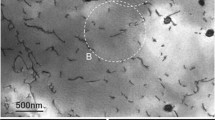

The fatigue crack growth rates for nickel-based superalloy Haynes 282 were measured at temperatures of 550, 650, and 750 °C using compact tension specimens with a load ratio of 0.1 and cyclic loading frequencies of 25 Hz and 0.25 Hz. Increasing the temperature from 550 to 750 °C caused the fatigue crack growth rates to increase from ~20 to 60% depending upon the applied stress intensity level. The effect of reducing the applied loading frequency increased the fatigue crack growth rates from ~20 to 70%, also depending upon the applied stress intensity range. The crack path was observed to be transgranular for the temperatures and frequencies used during fatigue crack growth rate testing. At 750 °C, there were some indications of limited intergranular cracking excursions at both loading frequencies; however, the extent of intergranular crack growth was limited and the cause is not understood at this time.

Similar content being viewed by others

Abbreviations

- R :

-

Load ratio

- P min :

-

Minimum load

- P max :

-

Maximum load

- ΔK :

-

Stress intensity range

- a :

-

Crack length

- W :

-

Specimen width

- B :

-

Specimen thickness

- C p :

-

Paris constant

- m :

-

Paris slope constant

- σ:

-

Yield strength

- E :

-

Young’s modulus

- T :

-

Temperature

- F :

-

Frequency

- da/dN :

-

The crack growth rate per cycle

References

R. Viswanathan, J.F. Henry, J. Tanzosh, G. Stanko, J. Shingledecker, B. Vitalis, and R. Purgert, U.S. Program on Materials Technology for Ultra-Supercritical Coal Power Plants, J. Mater. Eng. Perfor., 2013, 22(10), p 2904–2915. doi:10.1007/s11665-013-0717-6

R. Viswanathan, J.A. Hawk, R.C. Schwant, D. Saha, T. Totemeier, S. Goodstine, M. Mcnally, and D.B. Allen, Steam Turbine Materials for Ultrasupercritical Coal Power Plants, Final Technical Report, DOE DE-FC26- 05NT42442/OAQDA-OCDO 05-02(B), 2009, 535 p

L.M. Pike, Long Term Thermal Exposure of HAYNES 282 Alloy. Superalloy 718 and Derivatives, 2012, p 645–660. Retrieved from http://onlinelibrary.wiley.com/doi/10.1002/9781118495223.ch50/summary

L.M. Pike and S.K. Srivastava Oxidation Behavior of Wrought Gamma-Prime Strengthened Alloys. Materials Science Forum. 595–598, 2008, p 661–671. doi:10.4028/www.scientific.net/MSF.595-598.661

L.M. Pike, Low-Cycle Fatigue Behavior of HAYNES, in Turbo Expo 2007, Vol. 5, 2007, p 161–169. doi:10.1115/GT2007-28267

Haynes® International Haynes® 282® Alloy, 2006. Retrieved from http://www.haynesintl.com/pdf/h3173.pdf. Accessed 1 Jan 2015.

R.A. Buckson and O.A. Ojo, Cyclic Deformation Characteristics and Fatigue Crack Growth Behaviour of a Newly Developed Aerospace Superalloy Haynes 282, Mater. Sci. Eng. A, 2012, 555, p 63–70. doi:10.1016/j.msea.2012.06.034

C.J. Boehlert and S.C. Longanbach, A Comparison of the Microstructure and Creep Behavior of Cold Rolled HAYNES® 230 alloytm and HAYNES® 282 alloytm, Mater. Sci. Eng. A, 2011, 528(15), p 4888–4898. doi:10.1016/j.msea.2011.03.019

L.M. Pike, ASME Turbo Expo 2006: Power for Land, Sea and Air, in Haynes 282 Alloy—A New Wrought Superalloy Designed for Improved Creep Strength and Fabricabilty, GT2006-91204, Barcelona, 2006, p 1–9.

S. Ismonov, A. Loghin, T. Hanlon, and C. Shen, Application of Crack Tip Plasticity Based Fatigue Model on High Temperature Alloy HAYNES® 282®, Int. J. Fatigue, 2015, 70, p 146–153. doi:10.1016/j.ijfatigue.2014.08.015

S. Everitt, R. Jiang, N. Gao, M.J. Starink, J.W. Brooks, and P.A. Reed, Comparison of Fatigue Crack Propagation Behaviour in Two Gas Turbine Disc Alloys Under Creep–Fatigue Conditions: Evaluating Microstructure, Environment and Temperature Effects, Mater. Sci. Technol., 2013, 29(7), p 781–787. doi:10.1179/1743284713Y.0000000229

B.S. Adair, W.S. Johnson, S.D. Antolovich, and A. Staroselsky, Identification of Fatigue Crack Growth Mechanisms in IN100 Superalloy as a Function of Temperature and Frequency, Fatigue Fract. Eng. Mater. Struct., 2013, 36(3), p 217–227. doi:10.1111/j.1460-2695.2012.01715.x

G. Onofrio, G.A. Osinkolu, and M. Marchionni, Effects of Loading Waveform on Fatigue Crack Growth of Udimet 720 Li Superalloy, Int. J. Fatigue, 2004, 26(3), p 203–209. doi:10.1016/S0142-1123(03)00170-1

K.A. Rozman Characterization of High Temperature Fatigue Mechanisms in Haynes 282 Nickel Based Superalloy. Doctoral dissertation, Oregon State University, Corvallis, 2014

ASTM Standard E647 – 11: Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM International, West Conshohocken, PA, 2011. doi:10.1520/E0647-13AE01, www.astm.org.

P. Paris and F. Erdogan, A Critical Analysis of Crack Propagation Laws, J. Fluids Eng., 1963, 85(4), p 528–533. doi:10.1115/1.3656900

S. Suresh, Fatigue of Materials, 2nd ed., Cambridge University Press, Cambridge, 2004

Acknowledgment

This research was supported in part by an appointment to the U.S. Department of Energy (DOE) Postgraduate Research Program at the National Energy Technology Laboratory administered by the Oak Ridge Institute for Science and Education. The authors would also like to thank Dr. Rawley Greene for experimental support and technical programming.

Disclaimer

This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rozman, K.A., Kruzic, J.J. & Hawk, J.A. Fatigue Crack Growth Behavior of Nickel-base Superalloy Haynes 282 at 550-750 °C. J. of Materi Eng and Perform 24, 2841–2846 (2015). https://doi.org/10.1007/s11665-015-1588-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1588-9