Abstract

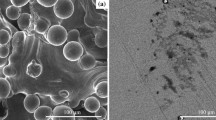

Haemocompatibility of Nitinol implantable devices and their corrosion resistance as well as resistance to fracture are very important features of advanced medical implants. The authors of the paper present some novel methods capable to improve Nitinol implantable devices to some marked degree beyond currently used electropolishing (EP) processes. Instead, a magnetoelectropolishing process should be advised. The polarization study shows that magnetoelectropolished Nitinol surface is more corrosion resistant than that obtained after a standard EP and has a unique ability to repassivate the surface. Currently used sterilization processes of Nitinol implantable devices can dramatically change physicochemical properties of medical device and by this influence its biocompatibility. The Authors’ experimental results clearly show the way to improve biocompatibility of NiTi alloy surface. The final sodium hypochlorite treatment should replace currently used Nitinol implantable devices sterilization methods which rationale was also given in our previous study.

Similar content being viewed by others

References

T. Hryniewicz, K. Rokosz, R. Rokicki, Surface Investigation of NiTi Rotary Endodontic Instruments After Magnetoelectropolishing. Mater Res Soc Symp Proc. Vol. 1244E © 2009 Materials Research Society, p 21–32, Symposium 9. Biomaterials (of XVIII International Materials Research Congress, Cancun, Mexico), 2009, ISBN 978-1-60511-221-3. http://www.mrs.org/s_mrs/sec_subscribe.asp?CID=24949&DID=280254

R. Rokicki, T. Hryniewicz, and K. Rokosz, Modifying Metallic Implants with Magnetoelectropolishing, Med. Device Diagn. Ind., 2008, 30(1), p 102–111

T. Hryniewicz and K. Rokosz, On the Wear Inspection and Endurance Recovery of Nitinol Endodontic Files, PAK Meas. Autom. Monit., 2009, 55(4), p 247–250

R.J. Van Geuns, C. Tamburino, J. Fajadet, M. Vrolix, B. Witzenbichler, E. Eeckhout et al., Self-expanding Versus Balloon-Expandable Stents in Acute Myocardial Infarction: Results from the Apposition II, Study: Self-expanding Stents in ST-Segment Elevation Myocardial Infarction, JACC Cardiovasc. Interv., 2012, 5(12), p 1209–1219. doi:10.1016/j.jcin.2012.08.016

D. Stoeckel, Nitinol—A Material with Unusual Properties. CORDIS Endovascular Update, Issue 1, Johnson & Johnson Co, 1998. http://www.nitinol.com/media/reference-library/031.pdf

A. Schuessler, J. Salgues, M. Strobel, and G. Siekmeyer, Effect of Surface Quality and Microstructure on Fatigue Behavior of Nitinol Stent Components. Proceeding of the International Conference on Shape Memory and Superelastic Technologies. 2006, Pacific Grove, CA. http://www.admedes.com/sites/files/admedes/files/Effect_of_Surface_Quality_and_Microstructures_on_Fatigue_Behaviour_of_Nitinol_Stent_Components.pdf

R. Steegmueller, T. Fleckenstain, A. Schuessler, Is Electropolishing Equal Electropolishing? A Comparison Study for Nitinol Stents. Proceeding of the Materials & Processes for Medical Devices Conference, 2005, Boston, MA. http://www.admedes.com/electropolishing-equal-electropolishing-comparison-study-nitinol-stents

R. Rokicki and T. Hryniewicz, Nitinol Surface Finishing by Magnetoelectropolishing, Trans. Inst. Met. Finish., 2008, 86(5), p 280–285

R. Rokicki, W. Haider, and T. Hryniewicz, Influence of Sodium Hypochlorite Treatment of Electropolished and Magnetoelectropolished Nitinol Surfaces on Adhesion and Proliferation of MC3T3 Pre-osteoblast Cells, J. Mater. Sci. Mater. Med., 2012, 23(9), p 2127–2139. doi:10.1007/s10856-012-4696-1

D.W. Norwich and A. Fasching, A Study of the Effect of Diameter on the Fatigue Properties of NiTi Wire, J. Mater. Eng. Perform., 2009, 18(5–6), p 558–562

S.A. Shabalovskaya, G. Rondelli, and M. Rettenmayer, Nitinol Surfaces for Implantation, J. Mater. Eng. Perform., 2009, 18(5–6), p 470–474

R. Rokicki, Detecting Nitinol Surface Inclusions, Med. Device Diagn. Ind., 2010, 32(2), p 44–48

J.G. Marks, Jr., D.V. Belsito, V.A. DeLeo, J.F. Fawler, A.F. Fransway, H.I. Maibach, et al., North American Contact Dermatitis Group. 2003. North American Contact Dermatitis Group Patch-Test Results, 1998 to 2000. Am. J Contact Dermat., 2003, 14(2), p 59–62

M. Jain, S. Singh, and M. Cadeiras, A Case of Nitinol Allergy Causing Pericardial Tamponade, J. Invasive Cardiol., 2013, 25(9), p 180–182

Nitinol Devices & Components Inc. http://www.qmed.com/supplier/nitinol-devices-components

K.K. Das, S.N. Das, S.A. Dhundasi, Nickel, Its Adverse Health Effects and Oxidative Stress. Indian J. Med. Res., 2008, 128, p 412–425. http://icmr.nic.in/ijmr/2008/october/1005.pdf

T. Zhao, Y. Li, X. Zhao, H. Chen, and T. Zhang, Ni Ion Release, Osteoblast-Material Interactions, and Hemocompatibility of Hafnium-Implanted NiTi Alloy, J. Biomed. Mater. Res. B, 2012, 100B, p 646–659

S.A. Shabalovskaya, J. Anderegg, and J. van Humbeeck, Critical Overview of Nitinol Surfaces and Their Modifications for Medical Applications, Acta Biomater., 2008, 4, p 447–467

D. Starosvetsky and I. Gotman, Corrosion Behavior of Titanium Nitride Coated Ni-Ti Shape Memory Surgical Alloy, Biomaterials, 2001, 22, p 1853–1859

D.L.L. Madamba, The Effect of Surface Treatment on Nickel Leaching from Nitinol. SJSU Scholar Works, Master’s Theses. Paper 4287, San Jose State University, CA, 2013. http://scholarworks.sjsu.edu/cgi/viewcontent.cgi?article=7834&context=etd_theses

J. Galante, J. Lemons, M. Spector, P. Wilson, and T. Wright, The Biological Effect of Implants Material, J. Orthop. Res., 1999, 9, p 760–775

E. Evans, Cell Damage In Vitro Following Direct Contact with Fine Particles of Titanium, Titanium Alloys and Cobalt-Chromium-Molybdenum Alloy, Biomaterials, 1994, 15, p 713–717

R. Rokicki, Method for Surface Inclusions Detection in Nitinol Which are Primary Corrosion and Fatigue Initiation Sites and Indicators of Overall Quality of Nitinol Material. US Patent 8377237, 2013

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rokicki, R., Hryniewicz, T., Pulletikurthi, C. et al. Towards a Better Corrosion Resistance and Biocompatibility Improvement of Nitinol Medical Devices. J. of Materi Eng and Perform 24, 1634–1640 (2015). https://doi.org/10.1007/s11665-015-1429-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1429-x