Abstract

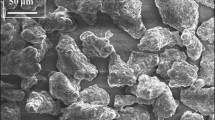

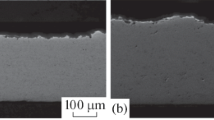

Cyclic oxidation behavior of detonation-gun-sprayed Ni-5Al coating on Inconel-718 is discussed in the present study. Oxidation studies were carried out on both bare and coated superalloy substrates in air at 900 °C for 100 cycles. The thermogravimetric technique was used to establish kinetics of oxidation. X-ray diffraction, FESEM/EDAX, and x-ray mapping techniques were used to analyze the oxidation products of bare and coated samples. The weight gain of bare superalloy was higher than the Ni-5Al-coated superalloy. Both bare and Ni-5Al-coated superalloys followed nearly parabolic oxidation behavior. The Ni-5Al coating was able to reduce the overall weight gain by 26.2% in comparison with bare superalloy in the given environment. The better oxidation resistance of Ni-5Al coating may be due the formation of protective oxides phases such as NiO, Al2O3, and NiAl2O4 on the oxidized coating and Cr2O3 at the coating-substrate interface. The Ni-5Al coatings obtained from detonation-gun-spraying process showed very little porosity and low surface roughness values.

Similar content being viewed by others

References

L. Geng, Y.S. Na, and N.K. Park, Oxidation Behavior of Alloy 718 at a High Temperature, Mater. Des., 2007, 28, p 978–981

H. Singh, D. Puri, and S. Prakash, An Overview of Na2SO4 and/or V2O5 Induced Hot Corrosion of Fe- And Ni-Based Superalloys, Rev. Adv. Mater. Sci., 2007, 16, p 27–50

T.S. Sidhu, A. Malik, S. Prakash, and R.D. Agrawal, Oxidation and Hot Corrosion Resistance of HVOF WC-NiCrFeSiB Coating on Ni- and Fe-Based Superalloys at 800 °C, J. Therm. Spray Technol., 2007, 16(5–6), p 844–849

N. Eliaz, G. Shemesh, and R.M. Latannision, Hot Corrosion in Gas Turbine Components, Eng. Fail. Anal., 2002, 9, p 31–43

H. Singh, S. Prakash, D. Puri, and D.M. Phase, Cyclic Oxidation Behavior of Some Plasma-Sprayed Coatings in Na2SO4-60%V2O5 Environment, J. Mater. Eng. Perform., 2006, 15(6), p 729–741

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Hot Corrosion Resistance of High-Velocity Oxyfuel Sprayed Coatings on a Nickel-Base Superalloy in Molten Salt Environment, J. Therm. Spray Technol., 2006, 15(3), p 387–399

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Performance of High-Velocity Oxyfuel-Sprayed Coatings on an Fe-Based Superalloy in Na2SO4-60%V2O5 Environment at 900 °C, Part I: Characterization of the Coatings, J. Mater. Eng. Perform., 2005, 15(1), p 122–129

G. Sundararajan, K.U.M. Prasad, D.S. Rao, and S.V. Joshi, A Comparative Study of Tribological Behaviour of Plasma and D-Gun Sprayed Coatings under Different Wear Modes, J. Mater. Eng. Perform., 1998, 7(3), p 343–351

P. Saravanan, V. Selvarajan, D.S. Rao, S.V. Joshi, and G. Sundararajan, Influence of Process Variables on the Quality of Detonation Gun Sprayed Alumina Coatings, Surf. Coat. Technol., 2000, 123(1), p 44–54

S. Kamal, R. Jayaganthan, S. Prakash, and S. Kumar, Hot Corrosion Behaviour of Detonation Gun Sprayed Cr3C2-NiCr Coatings on Ni and Fe-Based Superalloys in Na2SO4-60% V2O5 Environment at 900 °C, J. Alloys Compd., 2008, 463, p 358–372

S. Kamal, R. Jayaganthan, and S. Prakash, Hot Corrosion Studies of Detonation-Gun-Sprayed NiCrAlY + 0.4 wt.% CeO2 Coated Superalloys in Molten Salt Environment, J. Mater. Eng. Perform., 2011, 20(6), p 1068–1077

G. Kaushal, H. Singh, and S. Prakash, Performance of Detonation Gun-Sprayed Ni-20Cr Coating on ASTM A213 TP347H Steel in a Boiler Environment, J. Therm. Spray Technol., 2012, 21(5), p 975–986

S. Saladi, J. Menghani, and S. Prakash, High Temperature Oxidation Behaviour of Detonation-Gun-Sprayed Cr3C2-NiCr-CeO2 Coatings on Inconel-718 at 900 °C, ASME Turbo Expo, ASME, 2014

C. Senderowski, D. Zasada, T. Durejko, and Z. Bojar, Characterization of As-Synthesized and Mechanically Milled Fe-Al Powders Produced by the Self-Disintegration Method, Powder Technol., 2014, 263, p 96–103

C. Senderowski and Z. Bojar, Gas Detonation Spray Forming of Fe-Al Coatings in the Presence of Interlayer, Surf. Coat. Technol., 2008, 202(15), p 3538–3548

C. Senderowski and Z. Bojar, Influence of Detonation Gun Spraying Conditions on the Quality of Fe-Al Intermetallic Protective Coatings in the Presence of NiAl and NiCr Interlayers, J. Therm. Spray Technol., 2009, 18(3), p 435–447

C. Senderowski, A. Pawłowski, Z. Bojar, W. Wołczyński, M. Faryna, J. Morgiel, and Ł. Major, TEM Microstructure of Fe-Al Coatings Detonation Sprayed onto Steel Substrate, Arch. Metall. Mater., 2010, 55(2), p 373–381

C. Senderowski, Z. Bojar, W. Wołczyński, and A. Pawłowski, Microstructure Characterization of D-Gun Sprayed Fe-Al Intermetallic Coatings, Intermetallics, 2010, 18(7), p 1405–1409

C. Senderowski, Nanocomposite Fe-Al Intermetallic Coating Obtained by Gas Detonation Spraying of Milled Self-Decomposing Powder, J. Therm. Spray Technol., 2014, 23(7), p 1124–1134

S. Kamal, R. Jayaganthan, and S. Prakash, High Temperature Oxidation Studies of Detonation-Gun-Sprayed Cr3C2-NiCr Coating on Fe- and Ni-Based Superalloys in Air Under Cyclic Condition at 900 °C, J. Alloys Compd., 2009, 472, p 378–389

J.T. Chang, A. Davison, J.L. He, and A. Matthews, Deposition of Ni-Al-Y Alloy Films Using a Hybrid Arc Ion Plating and Magnetron Sputtering System, Surf. Coat. Technol., 2006, 200(20–21), p 5877–5883

D. Zhong, J.J. Moore, T.R. Ohno, J. Disam, S. Thiel, and I. Dahan, Deposition and Characterization of NiAl and Ni-Al-N Thin Films from a NiAl Compound Target, Surf. Coat. Technol., 2000, 130(1), p 33–38

R.D. Noebe, R.R. Bowman, and M.V. Nathal, Physical and Mechanical Properties of the B2 Compound NiAl, Int. Mater. Rev., 1993, 38(4), p 193–232

D.B. Miracle, Overview No. 104 The Physical and Mechanical Properties of NiAl, Acta Metall. Mater., 1993, 41(3), p 649–684

R.A. Mahesh, R. Jayaganthan, and S. Prakash, Oxidation Behavior of HVOF Sprayed Ni-5Al Coatings Deposited on Ni- and Fe-Based Superalloys Under Cyclic Condition, Mater. Sci. Eng. A, 2008, 475(1–2), p 327–335

R. Rajendran, Gas Turbine Coatings: An Overview, Eng. Fail. Anal., 2012, 26, p 355–369

R.A. Mahesh, R. Jayaganthan, and S. Prakash, A Study on Hot Corrosion Behaviour of Ni-5Al Coatings on Ni- and Fe-Based Superalloys in an Aggressive Environment at 900 °C, J. Alloys Compd., 2008, 460(1–2), p 220–231

B.S. Sidhu and S. Prakash, Evaluation of the Corrosion Behaviour of Plasma-Sprayed Ni3Al Coatings on Steel in Oxidation and Molten Salt Environments at 900 °C, Surf. Coat. Technol., 2003, 166(1), p 89–100

B.S. Sidhu and S. Prakash, Degradation Behavior of Ni3Al Plasma-Sprayed Boiler Tube Steels in an Energy Generation System, J. Mater. Eng. Perform., 2005, 14(3), p 356–362

R.A. Mahesh, R. Jayaganthan, and S. Prakash, Microstructural Characterization and Hardness Evaluation of HVOF Sprayed Ni-5Al Coatings on Ni- and Fe-Based Superalloys, J. Mater. Process. Technol., 2009, 209(7), p 3501–3510

B.S. Sidhu, D. Puri, and S. Prakash, Characterisations of Plasma Sprayed and Laser Remelted NiCrAlY Bond Coats and Ni3Al Coatings on Boiler Tube Steels, Mater. Sci. Eng. A, 2004, 368(1–2), p 149–158

S.B. Mishra, S. Prakash, and K. Chandra, Studies on Erosion Behaviour of Plasma Sprayed Coatings on a Ni-Based Superalloy, Wear, 2006, 260(4–5), p 422–432

H. Choi, B. Yoon, H. Kim, and C. Lee, Isothermal Oxidation of Air Plasma Spray NiCrAlY Bond Coatings, Surf. Coat. Technol., 2002, 150(2–3), p 297–308

S. Saladi, J. Menghani, and S. Prakash, Hot Corrosion Behaviour of Detonation-Gun Sprayed Cr3C2-NiCr Coating on Inconel-718 in Molten Salt Environment at 900 °C., Trans Indian Inst Met., 2014. DOI: 10.1007/s12666-014-0383-x

W.H. Lee and R.Y. Lin, Hot Corrosion Mechanism of Intermetallic Compound Ni3Al, Mater. Chem. Phys., 2002, 77, p 86–96

Z. Chen, N.Q. Wu, J. Singh, and S.X. Mao, Effect of Al2O3 Overlay on Hot-Corrosion Behavior of Yttria-Stabilized Zirconia Coating in Molten Sulfate-Vanadate Salt, Thin Solid Films, 2003, 443(1–2), p 46–52

Acknowledgments

The authors would like to thank Dr. Mukul Gupta of UGC-DAE Consortium for Scientific Research, Indore for performing XRD analysis. The authors also wish to thank Mr. Hiren Upadhyay of SIC, NIT Surat for performing SEM/EDAX analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saladi, S., Menghani, J. & Prakash, S. A Study on the Cyclic Oxidation Behavior of Detonation-Gun-Sprayed Ni-5Al Coatings on Inconel-718 at 900 °C. J. of Materi Eng and Perform 23, 4394–4403 (2014). https://doi.org/10.1007/s11665-014-1240-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1240-0