Abstract

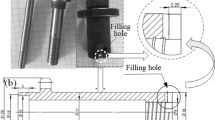

Keyhole left at 316L stainless steel friction stir welding/friction stir processing seam was repaired by filling friction stir welding (FFSW). Both metallurgical and mechanical bonding characteristics were obtained by the combined plastic deformation and flow between the consumable filling tool and the wall of the keyhole. Two ways based on the original conical and modified spherical keyholes, together with corresponding filling tools and process parameters were investigated. Microstructure and mechanical properties of 316L stainless steel FFSW joints were evaluated. The results showed that void defects existed at the bottom of the refilled original conical keyhole, while excellent bonding interface was obtained on the refilled modified spherical keyhole. The FFSW joint with defect-free interface obtained on the modified spherical keyhole fractured at the base metal side during the tensile test due to microstructural refinement and hardness increase in the refilled keyhole. Moreover, no σ phase but few Cr carbides were formed in the refilled zone, which would not result in obvious corrosion resistance degradation of 316L stainless steel.

Similar content being viewed by others

References

K.H. Lo, C.H. Shek, and J.K.L. Lai, Recent Developments in Stainless Steels, Mater. Sci. Eng. R, 2009, 65(4–6), p 39–104

C.W. Sun, R. Hui, W. Qu, and S. Yick, Progress in Corrosion Resistant Materials for Supercritical Water Reactors, Corros. Sci., 2009, 51(11), p 2508–2523

R.S. Mishra, M.W. Mahoney, S.X. McFadden, N.A. Mara, and A.K. Mukherjee, High Strain Rate Superplasticity in a Friction Stir Processed 7075 Al Alloy, Scripta Mater., 1999, 42(2), p 163–168

W.M. Thomas, E.D. Nicholas, J.C. NeedHam, M.G. Murch, P. Templesmith, and C.J. Dawes, Friction Stir Welding, GB Patent 9125978.8, Int Patent PCT/GB92/02203, 1991

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50, p 1–78

Z.Y. Ma, Friction Stir Processing Technology: A Review, Metall. Mater. Trans. A, 2008, 39, p 642–658

Z.Y. Ma, A.L. Pilchak, M.C. Juhas, and J.C. Williams, Microstructural Refinement and Property Enhancement of Cast Light Alloys Via Friction Stir Processing, Scripta Mater., 2008, 58, p 361–366

Y.C. Chen, H. Fujii, T. Tsumura, Y. Kitagawa, K. Nakata, K. Ikeuchi, K. Matsubayashi, Y. Michishita, Y. Fujiya, and J. Katoh, Friction Stir Processing of 316L Stainless Steel Plate, Sci. Technol. Weld. Join., 2009, 14, p 197–201

Y.C. Chen, H. Fujii, T. Tsumura, Y. Kitagawa, K. Nakata, K. Ikeuchi, K. Matsubayashi, Y. Michishita, Y. Fujiya, and J. Katoh, Banded Structure and Its Distribution in Friction Stir Processing of 316L Austenitic Stainless Steel, J. Nucl. Mater., 2012, 420, p 497–500

R.J. Ding, and A. Oelgoetzp, The Hydraulic Controlled Auto-adjustable Pin Tool for Friction Stir Welding, US Patent No. 5893507, 1996

C.D. Allen, and W.J. Arbegast, Evaluation of Friction Spot Welds in Aluminium Alloys, SAE Technical Paper No. 2005-01-1252, SAE International, Warrendale, PA, USA, 2005

Y. Uematsu, K. Tokaji, Y. Tozaki, T. Kutita, and S. Murata, Effect of Re-filling Probe Hole on Tensile Failure and Fatigue Behavior of Friction Stir Spot Welded Joints in Al-Mg-Si Alloy, Int. J. Fatigue, 2008, 30, p 1956–1966

S.B. Dunkerton, D.E. Nicholas, and P.D. Sketchley, Repairing Defective Metal Workpiece—By Friction Welding with a Metal Plug, Great Britain Patent Application No. 9125978, 1991

W.M. Thomas, and P. Temple-Smith, Friction Plug Extrusion for Solid-phase Welding Thick Plates—By Relatively Moving Consumable Member and Bore in Substrate while Urging Them Together to Generate Frictional Heat to Plasticize Member, Great Britain Patent Application No. 2306365, 1997

S.J. Unfried, M.T.P. Paes, T.F.C. Hermenegildo, F.L. Bastian, and A.J. Ramirez, Study of Microstructural Evolution of Friction Taper Plug Welded Joints of C-Mn Steels, Sci. Technol. Weld. Join., 2010, 15, p 506–513

P.J. Hartley, Friction Plug Weld Repair for the Space Shuttle External Tank, Weld. Met. Fabr., 2002, 9, p 6–8

Y.X. Huang, B. Han, Y. Tian, H.J. Liu, S.X. Lv, J.C. Feng, J.S. Leng, and Y. Li, New Technique of Filling Friction Stir Welding, Sci. Technol. Weld. Join., 2011, 16, p 497–501

Y.X. Huang, B. Han, S.X. Lv, J.C. Feng, H.J. Liu, J.S. Leng, and Y. Li, Interface Behaviors and Mechanical Properties of Filling Friction Stir Weld Joining AA 2219, Sci. Technol. Weld. Join., 2012, 17, p 225–230

Japanese Standards Association, Tensile Pieces for Tensile Test for Metallic Materials, JIS Z2201, 2004

ASTM International, Standard Test Methods for Determining Average Grain Size, ASTM E112-96, 2004

I. Woo, M. Aritoshi, and Y. Kikuchi, Metallurgical and Mechanical Properties of High Nitrogen Austenitic Stainless Steel Friction Welds, ISIJ Int., 2002, 42, p 401–406

L. Zhou, D. Liu, K. Nakata, T. Tsumura, H. Fujii, K. Ikeuchi, Y. Michishita, Y. Fujiya, and M. Morimoto, New Technique of Self-Refilling Friction Stir Welding to Repair Keyhole, Sci. Technol. Weld. Join., 2012, 17, p 649–655

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley Inc., Hoboken, 2005

M. Schwind, J. Kallqvist, J.O. Nilsson, J. Agren, and H.O. Andren, σ-Phase Precipitation in Stabilised Austenitic Stainless Steels, Acta Mater., 2000, 48, p 2473–2481

R.A. Farrar, Microstructure and Phase Transformations in Duplex 316 Submerged Arc Weld Metal, an Ageing Study at 700 °C, J. Mater. Sci., 1985, 20, p 4215–4231

Y.S. Sato and H. Kokawa, Preferential Precipitation Site of Sigma Phase in Duplex Stainless Steel Weld Metal, Scripta Mater., 1999, 40, p 659–663

S.H.C. Park, Y.S. Sato, H. Kokawa, K. Okamoto, S. Hirano, and M. Inagaki, Rapid Formation of the Sigma Phase in 304 Stainless Steel During Friction Stir Welding, Scripta Mater., 2003, 49, p 1175–1180

Y.S. Sato, N. Harayama, H. Kokawa, H. Inoue, Y. Tadokoro, and S. Tsuge, Evaluation of Microstructure and Properties in Friction Stir Welded Superaustenitic Stainless Steel, Sci. Technol. Weld. Join., 2009, 14, p 202–209

Acknowledgments

The work was funded by the “Innovative Nuclear Research and Development Program” of the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, L., Nakata, K., Tsumura, T. et al. Microstructure and Mechanical Properties of 316L Stainless Steel Filling Friction Stir-Welded Joints. J. of Materi Eng and Perform 23, 3718–3726 (2014). https://doi.org/10.1007/s11665-014-1124-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1124-3