Abstract

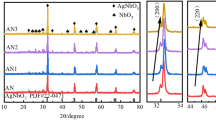

Sintered foils are currently being considered as a promising material for anode foils in capacitors due to their high specific capacitance and anti-buckling performance, which meet the requirements for capacitor winding. In this article, sintered foils with added starch were produced using a protective atmosphere sintering process. The effect of starch addition in the range of 0–50 vol% on the specific capacitance and anti-buckling performance of the sintered foils was evaluated. Scanning electron microscope (SEM) analysis confirmed the formation of the pores in the sintered foils due to the addition of starch. These pores play a crucial role in improving the specific capacitance and enhancing the anti-buckling performance of the sintered foils. However, excessive amounts of starch can have a negative impact on the specific capacitance of the sintered foils which initially decreased, then increased, and finally decreased with increasing starch content. On the other hand, the anti-buckling performance increased with increasing starch content. At 30 vol% starch addition, a high specific capacitance of 0.886 μF/cm2 and an anti-buckling performance of more than 120 times were obtained, meeting the requirements for anode foils in aluminum electrolytic capacitors. The specific capacitance of the sintered foils was predicted using the close-packed packing model, which can help establish a powder metallurgy method for preparing anode foil materials with high specific capacitance and anti-buckling performance for aluminum electrolytic capacitors.

Graphical Abstract

Similar content being viewed by others

References

J. Both, The modern era of aluminum electrolytic capacitors. IEEE Electr. Insul. M. 31, 24–34 (2015).

X.Q. Du, D.M. Cai, Q.X. Ou, D.C. Chen, Z. Zhang, and P. Liang, Fabrication and characterization of the hierarchical AAO film and AAO-MnO2 composite as the anode foil of aluminum electrolytic capacitor. Surf. Coat. Tech. 419, 127286 (2021).

H. Niu, S. Wang, X. Ye, H. Wang, and F. Blaabjerg, Lifetime prediction of aluminum electrolytic capacitors in LED drivers considering parameter shifts. Microelectron. Reliab. 88, 453 (2018).

T. Zednicek, M. Bárta, F. Corbett, and J. Frodl, Capacitor Trends and Challenges.

X.F. Du and Y.L. Xu, Formation of Al2O3-BaTiO3 composite thin film to increase the specific capacitance of aluminum electrolytic capacitor. Thin Solid Films 516, 8436 (2008).

Z. Liu, J. Wang, J. Chen, X. Liu, Y. Yin, and C. Ban, DC etching anode aluminum foil to form branch tunnels by electroless depositing Cu. Anti-Corr. Methods Mater. 66(6), 697–703 (2019).

S.Q. Zhu, C.L. Ban, X.Q. Tao, W.Y. Chen, and L.J. Jiang, Modelling specific capacitance of DC etched aluminium foil for aluminium electrolytic capacitor. J. Mater. Sci. Mater. El. 26, 6750 (2015).

C.L. Ban, Y.D. He, S. Xin, J. Du, and L.Q. Wang, Effect of chemical plating Zn on DC-etching behavior of Al foil in HCl-H2SO4. T. Nonferr. Metal. Soc. 23, 3650 (2013).

C.L. Ban, J.H. Chen, F.R. Wang, S.Q. Zhu, and Z.Q. Liu, Etching anode foil with branch tunnels for aluminum electrolytic capacitors. J. Nanosci. Nanotechno. 19, 7471 (2019).

N. Osawa and K. Fukuoka, Pit nucleation behavior of aluminium foil for electrolytic capacitors during early stage of DC etching. Corros. Sci. 42, 585 (2000).

L. Sun, J.F. Bu, W.X. Guo, Y.Y. Wang, M.Y. Wang, and C.J. Lin, Electrophoresis deposition of TiO2 nanoparticles on etched aluminum foil for enhanced specific capacitance. Electrochem. Solid-State Lett. 15, E1 (2011).

T. Balaji, R. Govindaiah, M.K. Sharma, Y. Purushotham, A. Kumar, and T.L. Prakash, Sintering and electrical properties of tantalum anodes for capacitor applications. Mater. Lett. 56, 560 (2002).

S. Sone, T. Taira, and M. Mehata, (2012) Electrode material for aluminum electrolytic capacitor and production method therefor, U.S. Patent Application: US20120231262A1

T. Taira, K. and Muramatsu, (2014) Method for producing electrode material for aluminum electrolytic capacitors, and electrode material for aluminum electrolytic capacitors, U.S. Patent Application: US10079111B2

T. Taira, K. Muramatsu, and M. Mehata, Electrode material for aluminum electrolytic capacitor, and method for producing same, U.S. Patent Application: US9330851B2; 2012.

T. Taira and M. Mehata, (2010) Electrode material for aluminum electrolytic capacitor and method for manufacturing the material, U.S. Patent Application: US20120094016A1

T. Taira and M. Mehata, (2021) Electrode material for aluminum electrolytic capacitor, and process for producing same, U.S. Patent Application: US20140098460A1

T. Taira and M. Mehata, (2013) Method for manufacturing electrode material for aluminum electrolytic capacitor, U.S. Patent Application: US20140368975A1

T. Taira and M. Mehata, (2006) Electrode material for aluminum electrolytic capacitor and method for producing the same, J.P. Patent Application: JP4958510B2

H.S. Liu, L. Yu, G. Simon, K. Dean, and L. Chen, Effects of annealing on gelatinization and microstructures of corn starches with different amylose/amylopectin ratios. Carbohyd. Polym. 77, 662 (2009).

X.X. Liu, Y.F. Wang, L. Yu, Z. Tong, L. Chen, H.S. Liu, and X.X. Li, Thermal degradation and stability of starch under different processing conditions. Starch-Stärke 65, 48 (2013).

J. Zhi, Y.F. Wang, S. Deng, and A. Hu, Study on the relation between pore size and supercapacitance in mesoporous carbon electrodes with silica-supported carbon nanomembranes. RSC Adv. 4, 40296 (2014).

Japanese Industrial Standard Committee. For folding endurance test. JIS P 8115.

Acknowledgments

This work was financially supported by the Key Research and Development Program of Shaanxi (No. 2023-YBGY-463).

Funding

Key Research and Development Program of Shaanxi, 2023-YBGY-463, Guangzhu Bai.

Author information

Authors and Affiliations

Contributions

GB: Investigation, Methodology, Validation, Conceptualization, Writing-Review & Editing, Funding acquisition, Project administration. ZC: Investigation, Validation, Formal analysis, Writing draft. JL: Methodology, Investigation. FW: Writing-Review & Editing. YZ: Methodology, Validation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bai, G., Chen, Z., Liu, J. et al. Microstructure Evolution and Performance Enhancement of Sintered Aluminum Foils for Aluminum Electrolytic Capacitors. J. Electron. Mater. 53, 2026–2039 (2024). https://doi.org/10.1007/s11664-024-10947-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-024-10947-8