Abstract

This article offers a unique method for improving the performance of AlGaN/GaN high-electron-mobility transistors (HEMTs) by combining an AlN interfacial passivation layer with a gate-all-around (GAA) structure, known as a GAA-MIS-HEMT. The carrier concentration, electric field dispersion, and current density of the AlGaN/GaN interface are all strategically improved by the GAA approach. To achieve higher device performance, the two-dimensional electron gas is controlled with greater precision. The results of the GAA-MIS-HEMT configuration are carefully compared to those of the traditional planar-MIS-HEMT in this study, which uses an \(\textrm{Al}_{2}\textrm{O}_{3}\) dielectric. The findings unequivocally establish the superiority of the GAA-MIS-HEMT, showing significant gains in ON-state current, OFF-state current, transconductance, cutoff frequency (11 GHz), ON-state to OFF-state current ratio (\(10^{11}\)), ON-state resistance (0.9 \(\Omega \)−\(\textrm{cm}^{2}\)), and subthreshold slope (63 mV/dec). Notably, the constituent layers of the proposed structure are all intended to be doping-free. This study illustrates the potential of the GAA-MIS-HEMT design with AlN passivation for advanced electronic applications, opening up intriguing paths for improving AlGaN/GaN HEMT performance.

Similar content being viewed by others

Introduction

Silicon has long been the main element in many power electronics devices. However, the investigation of alternative materials for power applications is necessary because of the increased demand for higher current, voltage, energy efficiency, and power density. The search for new materials is prompted by the intrinsic constraints of silicon, including its saturation velocity, operating efficiency, voltage management, temperature tolerance, and power capacity.

Given these intrinsic limitations of silicon, wider-bandgap materials with potential to address these issues have emerged, including silicon carbide (SiC), gallium arsenide (GaAs), and gallium nitride (GaN). In light of its extraordinary qualities including high critical field, significant bandgap width, respectable thermal conductivity, and remarkable saturation field, GaN stands out among these materials as a top contender for use in power devices.1 GaN has an advantage over other wide-bandgap semiconductors in that it can be deposited on less expensive silicon substrates, resulting in fewer interfacial defects. This compatibility makes GaN even more alluring. The innate polarization characteristics of the AlGaN/GaN layers causes a heterostructure to emerge. The two-dimensional electron gas (2DEG), a critical element, develops at the interface of these various bandgap materials. Through the use of the 2DEG at the heterojunction, this phenomenon enables high-electron-mobility transistors (HEMTs) to operate at high frequencies.

AlGaN/GaN, with its exceptional features, stands out as the best option for HEMTs designed for high-voltage, high-frequency, and low-noise applications. GaN HEMTs face difficulties such as significant leakage current and dynamic power loss brought on by applying a strong positive voltage across the Schottky barrier gate. To combat this, a metal–insulator–semiconductor HEMT (MIS-HEMT) structure has been found to be successful in reducing leakage current. \(\textrm{Al}_{2}\textrm{O}_{3}\), \(\textrm{HfO}_{2}\), \(\textrm{Si}_{3}\textrm{N}_{4}\), and \(\textrm{SiO}_{2}\) are among the carefully chosen gate dielectric materials, and their selection has accelerated the search for high transconductance and low leakage current. \(\textrm{Al}_{2}\textrm{O}_{3}\) is used as the gate dielectric in this work, and an AlN layer is added to enhance the quality of the interface between \(\textrm{Al}_{2}\textrm{O}_{3}\) and GaN. This decision is supported by the fact that AlN and GaN have a favorable lattice mismatch, making it a great candidate to bridge the GaN–\(\textrm{Al}_{2}\textrm{O}_{3}\) contact and eventually improving device performance and reliability.2,3

GaN-based HEMT performance can be improved by adopting a gate-all-around (GAA) architecture and concentrating on size reduction. GaN HEMTs are used in a variety of industries, most notably satellite and broadband wireless communication.4,5 The difficulty, though, is in reducing device size without sacrificing performance, as doing so may result in negative consequences such as reduced carrier transport efficiency, increased leakage current, and the appearance of short-channel effects (SCEs).6 A variety of solutions may be used to effectively address SCEs and the issues they raise.7,8,9,10,11,12 These include the use of source–drain engineering, gate-all-around (GAA) MOSFET technology, double-material gates, triple-material gates, dual-gate technology, omega field-effect transistors (FET), and FinFETs.13,14,15,16 The GAA FET stands out among them as being particularly promising since it provides a clear benefit in terms of drain current, transconductance, and successfully reducing SCEs that result from scaling down device dimensions.17,18,19 The encircling gate arrangement, a distinguishing feature of the GAA-FET, maintains fine control over the channel’s electrostatic potential and yields notable performance improvements.20,21,22 This strategy is essential for optimizing performance while taking into account the need for shrinking the size of GaN HEMTs.

The main goal of this work is the introduction and analysis of the gate-all-around metal–insulator–semiconductor AlGaN/GaN high-electron-mobility transistor (GAA-MIS-AlGaN/GaN HEMT) design. This is followed by a thorough comparison with the standard planar-MIS-AlGaN/GaN HEMT configuration. Critical factors are highlighted when the analog performance of both devices is painstakingly evaluated. A thorough analysis of the results reveals significant performance differences between the two systems. In comparison to its planar-MIS counterpart, the GAA-AlGaN/GaN HEMT structure outperforms it in terms of drain current, transconductance, cutoff frequency, and ON-state resistance. These differences highlight the potential benefits of the unique GAA-MIS architecture and point to its appropriateness for cutting-edge electronic applications.

Device Structure and Simulation Parameters

In order to create an AlGaN/GaN HEMT, materials with different bandgaps must be strategically arranged: AlGaN, which has a larger bandgap, is grown on top of GaN, which has a smaller bandgap. The AlGaN layer is specifically positioned above the GaN layer as the topmost layer. At the interface of this heterojunction, a two-dimensional electron gas (2DEG) is produced as a result of an offset caused by the different conduction band levels of these two materials.7 A potential well is created by this configuration within the GaN area. A homogeneous lattice arrangement creates a spontaneous polarization field in the GaN area. While this is happening, spontaneous and piezoelectric polarization fields are created inside the AlGaN layer when it is deposited over the GaN layer. The lattice strain in the AlGaN structure is what causes these polarization fields. The 2DEG forms at the interface as a result of the different field patterns between these two materials. The fact that this phenomenon occurs without the need for doping the AlGaN material is significant, since the underlying principles are based on the unique characteristics and configuration of the materials themselves.3 This setup is essential in laying the groundwork for the AlGaN/GaN HEMT’s performance and operation.

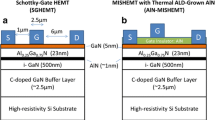

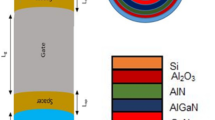

The proposed HEMT design has an AlGaN layer without any doping, and the aluminum (Al) component of the GaN composition is fixed at 0.25. In order to maximize performance, the gate-to-first-source and gate-to-drain spacing are both carefully tuned to 10 nm. To reduce series resistance, the secondary source and drain regions are configured to extend from the device’s edge to the top portion of the GaN layer. The silicon substrate that this design is based on acts as both a mechanical support and the device’s framework. The device’s cross-sectional view is shown in Fig. 1, together with a detailed three-dimensional (3D) schematic and a top view of the GAA-MIS AlGaN/GaN HEMT. The silicon substrate is 0.2 \(\upmu \)m thick.

In the case of MIS-AlGaN/GaN HEMTs, the foundation is a silicon substrate with thickness of 0.4 \(\upmu \)m. A 0.186-\(\upmu \)m-thick intrinsic GaN layer produced on a silicon substrate is among the succeeding layers. A doping-less AlGaN layer with a bandgap that is 20 nm thick is then deposited on top of this. In order to improve the interface between the two dielectric layers—an AlN layer with a thickness of 2 nm and an \(\textrm{Al}_{2}\textrm{O}_{3}\) layer with a thickness of 4 nm—a layer of AlN is positioned above the AlGaN layer. Au/Ni is the metal used for the gate. The entire length of the device is set at 2 \(\upmu \)m.

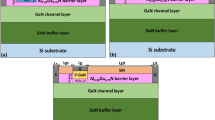

The architectural feature of the single-gate and gate-all-around designs is the fundamental difference between the planar and GAA-HEMT setups as shown in Fig. 2. Notably, the GAA-HEMT architecture efficiently confines electrons within the channel to achieve better transport properties. By improving current density and linearity, the complete 2DEG creation in the GAA-HEMT combination considerably improves device performance. This improvement results in increased output current, transconductance, and output resistance, which improves device performance overall.8 The Silvaco ATLAS-3D device simulator is a key tool for technology computer-aided design (TCAD) simulations.9 Key models, including the Shockley–Read–Hall model and mobility model, are used in these simulations. The physical dimensions of the proposed structure match those described by Soma,10 and the calibration of model parameters is carried out based on the work of Hwang et al.11

Figure 3 displays the model parameters used during the modeling of the AlGaN/GaN HEMT devices. This calibration procedure guarantees dimension and configuration consistency, supporting the accuracy and applicability of the simulations of the proposed structure. The proposed structure and the reference work may be meaningfully compared thanks to this calibration technique, making it easier to evaluate the properties and performance of the device.

AlGaN/GaN HEMT simulated \(I_\textrm{D}\)–\(V_\textrm{GS}\) characteristics calibration with Ref. 11.

Simulation Results and Discussion

Gate voltage and work function parameters are the same for the GAA-MIS-HEMT and planar-MIS-HEMT architectures. Figure 4a shows the production of the 2DEG in the ON state at the interface of two different bandgap materials, AlGaN and GaN. Notably, the 2DEG creation mechanism, which takes place at the heterojunction’s interface, is the same for both the GAA-MIS-HEMT and planar-MIS-HEMT designs. The depth of the 2DEG is significantly greater in the GAA-MIS-HEMT design, though, as a result of more exact control of the gate voltage. The increased depth and increased current density at the AlGaN/GaN contact are correlated. The energy band diagrams spanning the device length for the GAA-MIS-HEMT and planar-MIS-HEMT designs are shown in Fig. 4b and c in both the OFF and ON modes. The work function of the gate electrode causes the conduction band of the channel area to move upward in the OFF state. The conduction band underneath the channel area shifts lower in this condition as a result of the drain side receiving the proper biasing. As a result of the applied gate voltage, the ON state is distinguished by a higher electron density within the channel area. This increased electron density causes the conduction band in the channel area to move downward, which finally permits conduction. Due to the increased electron density in the channel area, the GAA-MIS-HEMT structure stands out for its lower conduction band in the ON state. This distinction highlights the positive effects of the GAA-MIS-HEMT architecture on the conduction properties of the device.

The distribution of current density throughout the device width is shown in Fig. 4d. Notably, the interface between the AlGaN and GaN materials shows a peak in electron current density. There is a decrease in electron density when the contact is crossed. When the device is in the ON state, current flow is only caused by moving electrons; throughout the device’s width, the hole current density is relatively low. It is crucial to stress that this unidirectional charge carrier behavior supports the device’s dominant electron-driven current. Additionally, the hole concentration profile of the GAA-MIS-HEMT design exhibits a distinguishing feature. Specifically, compared to the planar-MIS-HEMT design, the interface hole concentration is smaller. Due to this discrepancy, the hole current’s overall contribution to the drain current in both proposed devices is noticeably decreased. This finding emphasizes the minimal impact of hole current on the overall drain current, highlighting how the current behavior in both device topologies is mostly driven by electrons.

At a drain–source voltage (\(V_\textrm{ds}\)) of 10 V, Fig. 5a and b show the channel potential distribution over the device length in both the ON and the OFF modes. Interesting potential distribution patterns appear for both the GAA-MIS-HEMT and planar-MIS-HEMT designs. The Fermi level shifts upward in the OFF state as a result of the polarization field within the AlGaN layer, and the potential in the source and drain zones is increased. As a result, the channel potential increases to greater than 0 V and greater than 10 V, respectively, at the source–drain interface. When switching to the ON state, the potential distribution between the two configurations is preserved. The channel potential of the GAA-MIS-HEMT is noticeably higher, however, in the source and gate areas. The larger concentration of minority carriers is the cause of this increase in potential. The potential in the channel area moves higher by appropriate gate biasing. Importantly, the potential change from source to channel is less than the potential change from drain to source. Because of this mismatch in potential variation, the electric field shift at the source–channel interface is less in the OFF state. The GAA-MIS-HEMT design is notable for having a greater channel potential, which results in a stronger electric field at the source, drain, and channel interfaces during the ON state. Due to the greater mobility of the carriers, the higher electric field inherent to the GAA-MIS-HEMT architecture corresponds with improved carrier conduction.

The electron concentration distribution for the GAA-MIS-HEMT and planar-MIS-HEMT configurations in both the OFF and ON states are shown graphically in Fig. 6a and b. When compared to the planar-MIS-HEMT arrangement, the GAA-MIS-HEMT design displays a lower hole concentration in the channel area during the OFF state, resulting in a proportionally lower OFF-state current. Due to the application of the proper gate bias in the ON state, the electron concentration in the channel area shifts higher. Further amplifying the ON-state current is the increased electric field at the drain–channel contacts. Notably, the electron concentration in the channel region hovers around \(10^{19}\) \(\textrm{cm}^{-3}\). The importance of electron concentration dynamics in affecting both OFF-state and ON-state current is shown by this investigation. Additionally, the capacity of the GAA-MIS-HEMT design to control hole concentration leads to its particular performance benefits over the planar-MIS-HEMT configuration, eventually influencing how the device behaves in both the ON and OFF states.

At a drain–source voltage (\(V_{\textrm{ds}}\)) of 10 V, Fig. 7 shows the transfer characteristics for both the planar-MIS-HEMT and GAA-MIS-HEMT topologies on a logarithmic scale. It is clear from the graph analysis that the GAA-MIS-HEMT configuration’s drain current (\(I_{\textrm{ds}}\)) is greater than that of the planar-MIS-HEMT configuration. The GAA-MIS-HEMT’s enhanced control over the gate and the magnified electric field it experiences are responsible for this performance distinction. Specifically, compared to the planar-MIS-HEMT, the GAA-MIS-HEMT has a much higher ON-state current thanks to enhanced gate control and a wider electric field. The improved design of the GAA-MIS-HEMT and the resulting optimization of electron flow leads to this increased ON-state current. The GAA-MIS-HEMT architecture also exhibits decreased hole current density at the AlGaN and GaN contact. When compared to the planar-MIS-HEMT, this reduction results in a decreased OFF-state current for the GAA-MIS-HEMT. The GAA-MIS-HEMT arrangement consistently outperforms other configurations, and the transfer characteristics graph highlights this as well as the possibility for increased device capability.

With a larger ON-state current and a lower OFF-state current, the GAA-MIS-HEMT design exhibits a better performance ratio. When compared to the planar-MIS-HEMT design, the GAA-MIS-HEMT has a higher Ion/Ioff ratio thanks to this beneficial combination. For both the GAA-MIS-HEMT and planar-MIS-HEMT devices, the drain current (\(I_{\textrm{ds}}\)) is shown in Fig. 8 in response to the change of the drain–source voltage (\(V_{\textrm{ds}}\)) at a fixed gate–source voltage (\(V_{\textrm{gs}}\)) of 5 V. The graph clearly shows that the drain current of the GAA-MIS-HEMT configuration is higher than that of the planar-MIS-HEMT. The GAA-MIS-HEMT’s greater electron density, which leads to improved electron flow and, as a consequence, a larger drain current, is to blame for this performance disparity. The benefits provided by the GAA-MIS-HEMT’s particular architecture and design characteristics are highlighted by these findings, which confirm the device’s superiority in terms of current-carrying capacity and overall device performance.

The graph in Fig. 9 shows the relationship between the drain current (\(I_{\textrm{ds}}\)) and transconductance (\(g_\textrm{m}\)) in relation to the gate–source voltage (\(V_{\textrm{gs}}\)). The drain current (\(I_{\textrm{ds}}\)) for both of the proposed devices is shown in this graph as a solid line with a milliampere (mA) value. Notably, the GAA-MIS-HEMT greatly surpasses the planar-MIS-HEMT with a drain current of 910 mA/mm, whereas the planar-MIS-HEMT displays a drain current of 430 mA/mm.

The transconductance of the GAA-MIS-HEMT configuration is greater than that of the planar-MIS-HEMT because the GAA-MIS-HEMT exhibits a noticeably larger drain current (Ids). The GAA-MIS-HEMT’s improved performance in terms of its capacity to magnify the current response to fluctuations in the gate–source voltage, a critical feature of its functioning, is shown by this divergence in transconductance values.

The transconductance (\(g_\textrm{m}\)) is displayed against the gate voltage (\(V_{\textrm{gs}}\)) in Fig. 9 by the dotted line. The device’s driving effectiveness is directly impacted by the transconductance. Notably, increased drive efficiency is shown by a greater transconductance. The GAA-MIS-HEMT design provides a more effective driving capability, as seen in the graph, where the GAA-MIS-HEMT configuration demonstrates greater transconductance over the planar-MIS-HEMT. The performance of the device in various operational settings can be greatly improved by virtue of this feature. In Fig. 10, the total capacitance (\(C_{\textrm{gg}}\)), which is represented for both devices at a drain–source voltage (\(V_{\textrm{ds}}\)) of 10 V, is shown as the sum of the gate-to-drain capacitance (\(C_{\textrm{gd}}\)) and the gate-to-source capacitance (\(C_{\textrm{gs}}\)). It is vital to remember that the GAA-MIS-HEMT configuration has a significantly greater value of \(C_{\textrm{gg}}\) than the planar-MIS-HEMT configuration. The device’s switching behavior, which is essential to its operating features, is strongly influenced by total capacitance. The greater overall capacitance of the GAA-MIS-HEMT further emphasizes its potential for effective and efficient switching operations, increasing its usefulness in a variety of applications.

Equation 1 proves that a device’s cutoff frequency (\(f_\textrm{T}\)) depends on both its total capacitance (\(C_{\textrm{gg}}\)) and transconductance (\(g_\textrm{m}\)). In particular, the total capacitance is inversely proportional to the cutoff frequency and directly proportional to the transconductance. As a result, the cutoff frequency acts as a key sign of how well the device performs at high frequencies. In Fig. 11, the drain–source voltage (\(V_{\textrm{ds}}\)) at a fixed cutoff frequency (\(f_\textrm{T}\)) of 10 V is shown versus the gate voltage (\(V_{\textrm{gs}}\)). This graph demonstrates how the cutoff frequency responds to variations in gate voltage. The device’s operating frequency range’s top limit is indicated by the cutoff frequency, a crucial parameter. It shows how well a device can switch or amplify higher-frequency signals. This graph’s information makes it easier to comprehend how the cutoff frequency fluctuates with gate voltage and allows for a thorough evaluation of the device’s high-frequency performance. For the device to be used as efficiently as possible in high-frequency applications like wireless transmission and signal processing, this information is essential.

The cutoff frequency of a semiconductor device such as the GAA-AlGaN/GaN HEMT crucially depends on its physical dimensions. In the context of radio-frequency (RF) applications, the device’s cutoff frequency is significantly influenced by key geometric parameters like gate length, gate width, and gate oxide thickness. As the gate length decreases, the device exhibits improved high-frequency performance due to reduced transit times and improved carrier mobility. A smaller gate length translates to faster electron transit across the channel, effectively enhancing the device’s cutoff frequency. Moreover, minimizing the gate width and gate oxide thickness further aids in reducing parasitic capacitance and resistance, contributing to higher cutoff frequencies. Therefore, optimizing these dimensions in the GAA-AlGaN/GaN HEMT structure is essential for achieving superior high-frequency characteristics, ultimately enhancing its suitability for RF applications.

Transconductance (\(g_\textrm{m}\)) and total capacitance (\(C_{\textrm{gg}}\)) are two variables that affect a transistor’s cutoff frequency (\(f_\textrm{T}\)). The current density in the channel area is often lower when the gate bias voltage is lower than the threshold voltage. As a result, there is a decrease in transconductance, which has an impact on the cutoff frequency and lowers its value.

A crucial factor in high-frequency and RF applications is ON-state resistance (\(R_{\textrm{ON}}\)). It has a substantial impact on a device’s effectiveness and performance in certain situations. ON-state resistance (\(R_{\textrm{ON}}\)) and output transconductance (\(g_{\textrm{ds}}\)) at a fixed gate–source voltage (\(V_{\textrm{gs}}\)) of 5 V are displayed in Fig. 12 against the fluctuation in drain voltage (\(V_{\textrm{ds}}\)). The graph offers insightful information on how output transconductance and ON-state resistance respond to variations in drain voltage. In RF applications in particular, these metrics serve as important performance indicators for a device. To maximize the device’s performance in high-frequency situations, it is crucial to understand how they behave under various operating settings.

With a constant gate–source voltage (\(V_{\textrm{gs}}\)) of 5 V, Fig. 13 shows the subthreshold slope (SS) in relation to the applied drain voltage (\(V_{\textrm{ds}}\)). The change in the slope of the gate voltage with respect to the drain current is represented by the subthreshold slope. It offers insightful information regarding the device’s subthreshold performance, which is critical for low-power and analog applications. The device can switch between various current levels in the subthreshold region more smoothly if the subthreshold slope is smaller. This characteristic can lead to better performance in analog applications and is desirable for effective low-power operation.

Design Parameter Effects on Performance

Through the adjustment of different design parameters, the optimization of the GAA-AlGaN/GaN HEMT structure is followed in this section. These parameters range from 0.3 \(\upmu \)m to 1.2 \(\upmu \)m in gate length and gate work function, which ranges from 3.9 eV to 5.4 eV. Exploring these design factors seeks to improve the HEMT structure’s performance and features while ensuring that it complies with specific operating needs and intended results.

Gate Length \(L_\textrm{G}\) Variation and Its Effect

The effect of changing the gate length (\(L_\textrm{G}\)) is illustrated in Fig. 14, where (a) the change in \(I_{\textrm{ds}}\) with respect to \(V_{\textrm{gs}}\), (b) the change in the \(I_{\textrm{ON}}/I_{\textrm{OFF}}\) ratio with respect to gate length, (c) the change in threshold voltage (\(V_\textrm{TH}\)) with respect to gate length, and (d) the change in subthreshold slope (SS) with respect to gate length are all shown. It is clear from Fig. 14a and b that as gate length increases, ON-current fluctuation tends to be less pronounced than OFF-current variation. This phenomenon is related to the effect of positive ions in the channel area, which through correct work function application deplete the majority of charge carriers. As the gate length increases, this process slows the passage of majority carriers, resulting in a decrease in OFF-state current.

Due to the relatively greater change in \(I_{\textrm{ON}}\) compared to \(I_\textrm{OFF}\), the \(I_\textrm{ON}/I_\textrm{OFF}\) ratio increases as the gate length increases. The \(I_\textrm{ON}/I_\textrm{OFF}\) ratio reaches a value of \(10^{11}\) at a gate length of 1.2 \(\upmu \)m, where this trend is most prominent. When gate length is increased, there are very little variations in ON-state current due to the small fluctuation in carrier concentration inside the two-dimensional electron gas (2DEG). As shown in Fig. 14c, an increase in gate length results in an increase in threshold voltage. When there is no gate biasing, the extension of the gate depletes the bulk of the charge carriers in the channel area, making a larger gate bias necessary to invert the channel and generate an ON-state operation. This increase in threshold voltage results from a significant decrease in majority charge carriers, which necessitates stronger channel gating.

According to Fig. 14d, the subthreshold slope decreases as the gate length increases. This decrease is explained by the rising \(I_\textrm{ON}/I_\textrm{OFF}\) ratio as gate length increases. The increased ratio demonstrates a positive reaction to the longer gate length, which results in a lower subthreshold slope value.

The intricate connection between gate length variation and device performance is highlighted in this thorough examination, in particular with regard to ON-current, OFF-current, \(I_\textrm{ON}/I_\textrm{OFF}\) ratio, threshold voltage, and subthreshold slope.

Work Function Variation and Its Effect

Figure 15 provides a clear illustration of the impact of gate work function by showing the variation in Ids, the behavior of the \(I_\textrm{ON}/I_\textrm{OFF}\) ratio, the shift in threshold voltage, and the change in subthreshold slope, all in relation to the gate work function. Figure 15a and b reveals a trend where, as the gate work function increases, the variance in the OFF-state current exceeds that of the ON-state current. The interaction between the gate work function and the level of negative ions in the channel area is responsible for this tendency. More n-type behavior is produced when the gate work function is reduced because an increase in the population of negative ions follows. On the other hand, the result of increasing gate work function is the reverse. As a result, there is little difference in ON-state current.

Additionally, the lower carrier concentration linked to greater gate work function values results in a decrease in the OFF-state current. As a result, Fig. 15b illustrates an increase in the \(I_\textrm{ON}/I_\textrm{OFF}\) ratio. Notably, the \(I_\textrm{ON}/I_\textrm{OFF}\) ratio achieves a phenomenal value of \(10^{11}\) at a gate work function of 5.1 eV. The threshold voltage (Vth), as shown in Fig. 15c, increases with the increase in gate work function. This phenomenon is explained by the fact that when the gate work function increases, the channel becomes increasingly exhausted. Greater depletion necessitates stronger biasing in order to switch the device from OFF to ON state. Additionally, a significant decrease in ON-state current is a result of the increase in gate work function. This impact makes it easier to transition smoothly from OFF-state to ON-state operation, which improves the \(I_\textrm{ON}/I_\textrm{OFF}\) ratio. The lower subthreshold slope, shown in Fig. 15d, likewise shows this change.

Conclusion

In conclusion, the research and analysis in this work have shown the complex interaction of design factors and their influence on the functionality of the proposed GAA-AlGaN/GaN HEMT structure. The device’s ability to be used in high-frequency and RF applications has been made possible by the use of the gate-all-around (GAA) design, which was found to be crucial in improving many key characteristics of the device. The effective control of the majority carriers is shown by the decline in OFF-state current as the gate length increases, which dramatically improves the \(I_\textrm{ON}/I_\textrm{OFF}\) ratio. The modification of channel carrier concentration was further reflected in a direct link between threshold voltage and gate length. The device’s positive performance in switching applications was demonstrated by the decline in subthreshold slope with longer gates. The investigation of gate work function variation also demonstrated how crucial this factor is in determining the device behavior. The significant influence of shifting work function values on OFF-state current, together with the resulting fluctuations in carrier concentration and \(I_\textrm{ON}/I_\textrm{OFF}\) ratio, highlighted the significance of this parameter. Greater depletion caused by higher gate work functions affected the threshold voltage and facilitated smoother switching behavior. The GAA-HEMT, with improved characteristics, is suitable for high-frequency communication systems, including next-generation wireless communication technologies, facilitating faster data transmission and higher bandwidth.

References

Y.Y. Wong, Y.S. Chiu, T.T. Luong, T.M. Lin, Y.T. Ho, Y.C. Lin, and E.Y. Chang, Growth and fabrication of AlGaN/GaN HEMT on SiC substrate, in 2012 10th IEEE International Conference on Semiconductor Electronics (ICSE) (IEEE, 2012), pp. 729–732.

P.D. Ye, B. Yang, K.K. Ng, J. Bude, G.D. Wilk, S. Halder, and J.C.M. Hwang, GaN metal-oxide-semiconductor high-electron-mobility transistor with atomic layer deposited Al2O3 as gate dielectric. Appl. Phys. Lett. 86(6), 063501 (2005).

F. Roccaforte, G. Greco, P. Fiorenza, and F. Iucolano, An overview of normally-of GaN-based high electron mobility transistors. Materials 12(10), 1599 (2019).

Y. Ohno and M. Kuzuhara, Application of GaN-based heterojunction FETs for advanced wireless communication. IEEE Trans. Electron Devices 48(3), 517 (2001).

T. Palacios, A. Chakraborty, S. Heikman, S. Keller, S.P. DenBaars, and U.K. Mishra, AlGaN/GaN high electron mobility transistors with InGaN back-barriers. IEEE Electron Device Lett. 27(1), 13 (2005).

T.V. Kumar and N.B. Balamurugan, Analytical modeling of InSb/ AlInSbheterostructure dual gate high electron mobility transistors. AEU - Int. J. Electron. Commun. 94, 19 (2018).

M. Kumar, S. Haldar, M. Gupta, and R.S. Gupta, Impact of gate material engineering (GME) on analog/RF performance of nanowire Schottky-barrier gate all around (GAA) MOSFET for low power wireless applications: 3D T-CAD simulation. Microelectron. J. 45(11), 1508–1514 (2014).

J.T. Park and J.P. Colinge, Multiple-gate SOI MOSFETs: device design guidelines. IEEE Trans. Electron Devices 49(12), 2222 (2002).

P. Ghosh, S. Haldar, R.S. Gupta, and M. Gupta, Analytical modelling and simulation for dual metal gate stack architecture (DMGSA) cylindrical/surrounding gate MOSFET. J. Semicond. Technol. Sci. 12(4), 458 (2012).

U. Soma, A dual gate junctionless FinFET for biosensing applications. Silicon 14, 8881 (2022). https://doi.org/10.1007/s12633-021-01603-5.

I.H. Hwang, S.K. Eom, G.H. Choi, M.J. Kang, J.G. Lee, H.Y. Cha, and K.S. Seo, High-performance E-mode AlGaN/GaN MIS-HEMT with dual gate insulator employing SiON and HfON. Phys. Status Solidi (A) 215(10), 1700650 (2018).

H. Xiao-Guang, Z. De-Gang, and J. De-Sheng, Formation of two dimensional electron gas at AlGaN/GaN heterostructure and the derivation of its sheet density expression. Chin. Phys. B 24(6), 067301 (2015).

T.E. Hsieh, E.Y. Chang, Y.Z. Song, Y.C. Lin, H.C. Wang, S.C. Liu, S. Salahuddin, and C.C. Hu, Gate recessed quasi-normally OFF Al2O3/AlGaN/GaN MIS-HEMT with low threshold voltage hysteresis using PEALD AlN interfacial passivation layer. IEEE Electron Device Lett. 35(7), 732 (2014).

S. Panchanan, R. Maity, S. Baishya, and N.P. Maity, Modeling, simulation and analysis of surface potential and threshold voltage: application to high-K material HfO2 based FinFET. Silicon 13, 3271–3289 (2020).

Atlas user’s manual. (Silvaco, Santa Clara, 2016).

J.-P. Colinge, FinFETs and Other Multi-gate Transistors (Springer, New York, 2008).

R. Kumar and M. Panchore, Impact of back gate bias on analog performance of dopingless transistor. Trans. Electr. Electron. Mater. 24, 115 (2023).

S.S. Mohanty, S. Mishra, M. Mohapatra, and G. Prasad Mishra, Dielectrically modulated hetero channel double gate MOSFET as a label free biosensor. Trans. Electr. Electron. Mater. 23, 156 (2022).

A. Bhardwaj, P. Kumar, B. Raj, and S. Anand, Design and performance analysis of a GAA electrostatic doped negative capacitance vertical nanowire tunnel FET. J. Electron. Mater. 52, 3103 (2023).

D. Ghai, S.P. Mohanty, and G. Thakral, Comparative analysis of double gate FinFET configurations for analog circuit design, in 2013 IEEE 56th International Midwest Symposium on Circuits and Systems (MWSCAS) (Columbus, 2013), pp. 809–812.

S. Cho, K.R. Kim, B.G. Park, and I.M. Kang, RF performance and small-signal parameter extraction of junctionless silicon nanowire MOSFETs. IEEE Trans. Electron Devices 58(5), 1388 (2011).

U.K. Mishra, P. Parikh, and Y.F. Wu, AlGaN/GaN HEMTs-an overview of device operation and applications. Proc. IEEE 90(6), 1022 (2002).

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Ethics Approval

The author declares that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Soma, U. Enhancing AlGaN/GaN HEMT Performance through Gate-All-Around AlN Passivation: A Comparative Study with a Planar MIS-HEMT. J. Electron. Mater. 53, 2477–2487 (2024). https://doi.org/10.1007/s11664-024-10940-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-024-10940-1