Abstract

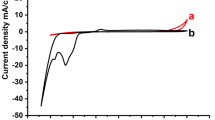

In this paper, titanium oxide (TiO2) films were prepared by cathodic electrodeposition using titanium oxysulfate (TiOSO4), potassium nitrate (KNO3), citric acid, and hydrogen peroxide (H2O2) as reactants. The article investigated the effect of citric acid and deposition temperature on the structure and electrochemical properties of TiO2 films. The results indicated that hydrous TiO2 thin films were prepared at 60°C when no citric acid was added, while thin films containing hydrous TiO2 and anatase phase were fabricated at 60–75°C when citric acid was added. It was found that adding citric acid and raising the reaction temperature (60–75°C) were beneficial to reduce crack width until cracks disappeared. Adding citric acid facilitated phase transition from hydrous TiO2 to anatase. Continuous and uniform TiO2 thin film was prepared at 75°C, which was found to have ideal capacitive behavior with a rectangular cyclic voltammogram and high photocurrent performance with photocurrent 2.89 μA, which is several times higher than that of cracked samples.

Similar content being viewed by others

References

T. Raguram and K.S. Rajni, J Sol-Gel Sci Tech. (2020). https://doi.org/10.1007/s10971-019-05180-3.

A.M. Peiró, J. Peral, C. Domingo, X. Domènech, and J.A. Ayllón, Chem. Mater. (2001). https://doi.org/10.1021/cm0012419.

L. Henrik, S. Sven, S. Anita, R. Haakan, H. Johan, H. Anders, and L. Sten-Eric, J Phys Chem B. (1997). https://doi.org/10.1021/jp970490q.

P. Parastoo Agharezaei, H. Hossein Abdizadeh, and M.R. Mohammad Golobostanfard, Ceram Inter. (2018). https://doi.org/10.1016/j.ceramint.2017.11.214.

C.M. Wang and S.Y. Lin, J. Solid State Electrochem. (2006). https://doi.org/10.1007/s10008-005-0690-6.

C. Esparza-Contro, G. Berthomé, G. Renou, F. Robaut, S. Coindeau, C. Vachey, J. Cambin, M. Mantel, and L. Latu-Romain, Surf. Coat. Technol. (2020). https://doi.org/10.1016/j.surfcoat.2020.125643.

A. Watanabe and Y. Imai, Thin Solid Films (1999). https://doi.org/10.1016/S0040-6090(99)00012-7.

K. Kamada, M. Mukai, and Y. Matsumoto, Electrochim. Acta (2002). https://doi.org/10.1016/S0013-4686(02)00251-7.

M. Chigane, T. Shinagawa, and J. Tani, Thin Solid Films (2017). https://doi.org/10.1016/j.tsf.2017.03.031.

I. Zhitomirsky, Adv. Colloid Interface Sci. (2002). https://doi.org/10.1016/S0001-8686(01)00068-9.

S. Patra, C. Andriamiadamanana, M. Tulodziecki, C. Davoisne, P.L. Taberna, and F. Frédéric Sauvage, Sci Rep. (2016). https://doi.org/10.1038/srep21588.

H. Chettah, D. Abdi, H. Amardjia, and H. Haffar, Ionics (2009). https://doi.org/10.1007/s11581-008-0246-8.

H. Liu, Z. Zheng, D. Yang, E. Waclawik, X. Ke, H. Zhu, S. Palmer, and R.L. Frost, J. Raman Spectrosc. (2010). https://doi.org/10.1002/jrs.2632.

C. Liu, X.H. Lu, G. Yu, X. Feng, Q. Zhang, and Z.Z. Xua, Mater. Chem. Phys. (2005). https://doi.org/10.1016/j.matchemphys.2005.05.022.

M. Vishwas, K.N. Rao, and R.P.S. Chakradhar, Spectrochim Acta A Mol. Biomol. Spectrosc. (2012). https://doi.org/10.1016/j.saa.2012.09.009.

O. Frank, M. Zukalova, B. Laskova, J. Ku¨rti, J. Koltai, and L. Kavan, Phys. Chem. Chem. Phys. (2012). https://doi.org/10.1039/c2cp42763j.

P.C.T. D’Ajello, M.A. Fiori, A.A. Pasa, and Z.G. Kipervaser, J. Electrochem. Soc. 147, 4562 (2000).

C. Natarajan and G. Nogami, J. Electrochem. Soc. 143, 1547 (1996).

X.L. Sui, Z.B. Wang, C.Z. Li, J.J. Zhang, L. Zhao, and D.M. Gu, J Power Sour. (2014). https://doi.org/10.1016/j.jpowsour.2014.08.074.

F. Cverna, Thermal properties of metals (Ohio: Materials Park, 2002), p. 9.

S.S. Jiang and K.F. Zhang, Mater. Des. (2009). https://doi.org/10.1016/j.matdes.2009.03.023.

A. Kraemer, C. Kunz, S. Graef, and F.A. Müller, Appl. Surf. Sci. (2015). https://doi.org/10.1016/j.apsusc.2015.07.055.

H. Zhu, Q. Li, Y. Ren, L. Fan, J. Chen, J. Deng, and X. Xing, Adv. Mater. (2016). https://doi.org/10.1002/adma.201600973.

X. Lu, G. Wang, T. Zhai, M. Yu, J. Gan, Y. Tong, and Y. Li, Nano Lett. (2012). https://doi.org/10.1021/nl300173j.

V.H. Pham, T.D. Nguyen-Phan, X. Tong, B. Rajagopalan, J.S. Chung, and J.D. Dickerson, Carbon (2018). https://doi.org/10.1016/j.carbon.2017.

X.Y. Cao, X. Xing, N. Zhang, H. Gao, M.Y. Zhang, Y.C. Shang, and X.T. Zhang, J. Mater. Chem. (2015). https://doi.org/10.1039/c4ta06138a.

L.H. Cui, Y. Wang, X. Shu, J.F. Zhang, C.P. Yu, J.W. Cui, H.M. Zheng, Y. Zhang, and Y.Y. Wu, RSC Adv. (2016). https://doi.org/10.1039/c5ra25581c.

X. Dong, J. Tao, Y. Li, and H. Zhu, Appl. Surf. Sci. (2010). https://doi.org/10.1016/j.apsusc.2009.10.100.

K.K. Supriyono, K.K. Yuni, and G. Jarnuzi, AIP Conference Proceed. (2016). https://doi.org/10.1063/1.4946952.

H. Chettah, D. Abdi, H. Amardjia, and H. Haffar, Ionics (2009). https://doi.org/10.1007/s11581-008-0246-8.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tao, Y., Zhu, B. Titanium Oxide Films Prepared by Cathodic Electrodeposition Method. J. Electron. Mater. 49, 7526–7531 (2020). https://doi.org/10.1007/s11664-020-08513-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08513-z