Abstract

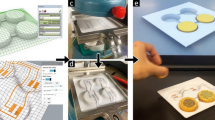

A major challenge in the flexible electronics industry is the inability to quickly and accurately assess the mechanical properties of barrier materials used to encapsulate various devices. The feasibility of using a low-cost approach, digital photoelasticity (DP), to determine stress formation in barrier film is analyzed so that inherent weak areas cannot only be identified, but also reinforced. In this experimental study, ethylene vinyl acetate (EVA) is slot die coated onto untreated polyethylene terephthalate (PET) or onto PET treated with indium tin oxide (ITO) or poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS). An axial stress is imposed on each sample using a universal test machine, and DP was used to obtain the stress and grab profiles. It has been shown that highly concentrated and multilayer EVA coatings withstand higher stress. Also, it has been shown that the locations of delamination happen at the side edge of the encapsulation when EVA was coated on a homogenous surface, but for heterogeneous surfaces, the delamination occurred at the boundary between the PEDOT:PSS and ITO. All these data were depicted using DP in very quick fashion. Therefore, DP is a viable method for quickly and accurately determining stress in barrier films.

Similar content being viewed by others

References

V. Kale and T.J. Riley, IEEE Trans. Parts Hyb. Packag. 13, 3 (1977).

W. Wong and A. Salleo, Flexible Electronics: Materials and Applications (Berlin: Springer, 2009), p. 16.

M. Kempe, Sol. Energy Mater. Sol. Cell 94, 246 (2010).

A.M. Henderson, IEEE Electr. Insul. Mag. 9, 30 (1993).

M. Spalding and A. Chatterjee, Handbook of Industrial Polyethylene and Technology (Hoboken: Wiley, 2017), p. 126.

N. Das, S. Yamazaki, T. Chaki, D. Khastgir, and A. Chakraborty, Polym. Int. 54, 256 (2005).

R. Mizan and A. Islam, Univers. J. Mater. Sci. 6, 49 (2018).

W. Stark, M. Jaunich, W. Bohmeyer, and K. Lange, Polym. Test. 31, 904 (2012).

T. Kinkeldei, N. Munzenrieder, C. Zysset, K. Cherenack, and G. Troster, IEEE Electr. Device Lett. 32, 1743 (2011).

J. Lewis and M. Weaver, IEEE J. Sel. Top. Quant. 10, 45 (2004).

A. Pierre, M. Sadeghi, M.M. Payne, A. Facchetti, J.E. Anthony, and A.C. Arias, Adv. Mater. 26, 5722 (2014).

A. Sandstrom, H. Dam, F. Krebs, and L. Edman, Nat. Commun. 3, 1002 (2012).

D. Perera, Prog. Org. Coat. 28, 21 (1996).

S.T. Shiue, C.H. Yang, R.S. Chu, and T.J. Yang, Thin Solid Films 485, 169 (2005).

O. van der Sluids, R.A.B. Engelen, P.H.M. Timmermans, and G.Q. Zhang, Microelectron. Reliab. 49, 853 (2009).

D. Vella, J. Bico, A. Boudaoud, B. Roman, and P. Reid, Proc. Natl. Acad. Sci. USA 106, 10901 (2009).

U. Welzel, J. Ligot, P. Lamparter, A.C. Vermeulen, and E.J. Mittemeijer, J. Appl. Crystallogr. 38, 1 (2005).

K. Ramesh, Meas. Sci. Technol. 11, 12 (2000).

R.G.R. Prasath, S. Danyluk, and S. Zagarola, Polym. Plast. Technol. Mater. 58, 1802 (2019).

R.G.R. Prasath, T. Newton, and S. Danyluk, Manuf. Lett. 15, 9 (2018).

R.G.R. Prasath, K. Skenes, and S. Danyluk, J. Electron. Mater. 42, 2478 (2013).

Acknowledgments

The authors would like to acknowledge the Department of Defense NextFlex Technology Hub for funding this work, Dr. Steven Danyluk for giving insights on Digital Photoelasticity, and Christine Taylor for setting up and training us to use the digital photoelasticity system.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jeong, TJ., Prasath, R.G.R., Sitaraman, S.K. et al. Visualization of Delamination in Encapsulated Flexible Electronics Fabricated using Slot Die Coating. J. Electron. Mater. 49, 3332–3339 (2020). https://doi.org/10.1007/s11664-020-08065-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08065-2