Abstract

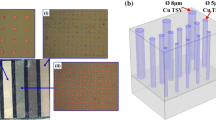

Through-silicon vias (TSV) are facing unexpected thermo-mechanical reliability problems due to the coefficient of thermal expansion (CTE) mismatch between various materials in TSVs. During applications, thermal stresses induced by CTE mismatch will have a negative impact on other devices connecting with TSVs, even leading to failure. Therefore, it is essential to investigate the stress distribution evolution in the TSV structure under thermal loads. In this report, TSVs were heated to 450°C at different heating rates, then cooled down to room temperature after a 30-min dwelling. After heating treatment, TSV samples exhibited different Cu deformation behaviors, including Cu intrusion and protrusion. Based on the different Cu deformation behaviors, stress in Si around Cu vias of these samples was measured and analyzed. Results analyzed by Raman spectrums showed that the stress distribution changes were associated with Cu deformation behaviors. In the area near the Cu via, Cu protrusion behavior might aggravate the stress in Si obtained from the Raman measurement, while Cu intrusion might alleviate the stress. The possible reason was that in this area, the compressive stress \( \sigma_{\theta }\) induced by thermal loads might be the dominant stress. In the area far from the Cu via, thermal loads tended to result in a tensile stress state in Si.

Similar content being viewed by others

References

I. Dutta, P. Kumar, and M.S. Bakir, Jom-Us 63, 70 (2011).

K. Kondo, in Proceedings of Electronic Components and Technology Conference (2016), pp. 1265–1270.

P. Kumar, I. Dutta, Z. Huang, and P. Conway, in 3D Microelectronic Packaging, ed. By Y. Li and D. Goyal (Springer, Cham, 2017), pp. 71–99.

C. Si, Q. Fei, A. Tong, and C. Pei, in Proceedings of Electronic Components and Technology Conference (2016), pp. 1599–1604.

Q. Zeng, W. Meng, Y. Guan, J. Chen, and Y. Jin, in Proceedings of Electronic Components and Technology Conference (2016), pp. 1797–1802.

A.S. Budiman, H.A.S. Shin, B.J. Kim, S.H. Hwang, H.Y. Son, M.S. Suh, Q.H. Chung, K.Y. Byun, N. Tamura, M. Kunz, and Y.C. Joo, Microelectron. Reliab. 52, 530 (2012).

T.F. Jiang, C.L. Wu, N. Tamura, M. Kunz, B.G. Kim, H.Y. Son, M.S. Suh, J. Im, R. Huang, and P.S. Ho, IEEE Trans. Device Mater. Reliab. 14, 698 (2014).

C. Okoro, P. Kabos, J. Obrzut, K. Hummler, and Y.S. Obeng, IEEE Trans. Electron Device 60, 2015 (2013).

C. Okoro, L.E. Levine, R.Q. Xu, K. Hummler, and Y.S. Obeng, IEEE Trans. Electron Device 61, 2473 (2014).

M. Song, K.R. Mundboth, J.A. Szpunar, L. Chen, and R.F. Feng, J. Micromech. Microeng. 25, 085002 (2015).

C. Okoro, L.E. Levine, R.Q. Xu, and Y. Obeng, J. Mater. Sci. 50, 6236 (2015).

I. De Wolf, in AIP Conference Proceedings (2011). pp. 138–149.

P. Bayat, D. Vogel, R.D. Rodriguez, E. Sheremet, D.R.T. Zahn, S. Rzepka, and B. Michel, Microelectron. Eng. 137, 101 (2015).

I. De Wolf, V. Simons, V. Cherman, R. Labie, B. Vandevelde, and E. Beyne, in Proceedings of Electronic Components and Technology Conference (2012), pp. 331–337.

W.S. Kwon, D.T. Alastair, K.H. Teo, S. Gao, T. Ueda, T. Ishigaki, K.T. Kang, and W.S. Yoo, Appl. Phys. Lett. 98, 232106 (2011).

C. Okoro, Y. Yang, B. Vandevelde, B. Swinnen, D. Vandepitte, B. Verlinden, and I. De Wolf, in Proceedings of the IEEE 2008 International Intercon nect Technology Conference (2008), pp. 16–18.

P. Saettler, M. Hecker, M. Boettcher, C. Rudolph, and K.J. Wolter, Microelectron. Eng. 137, 105 (2015).

T.F. Jiang, S.K. Ryu, Q. Zhao, J. Im, R. Huang, and P.S. Ho, Microelectron. Reliab. 53, 53 (2013).

W. Jiang and L. Wang, in Proceedings of International Conference on Electronic Packaging Technology (2015), pp. 226–230.

A.D. Trigg, L.H. Yu, C.K. Cheng, R. Kumar, D.L. Kwong, T. Ueda, T. Ishigaki, K. Kang, and W.S. Yoo, Appl. Phys. Express 3, 086601 (2010).

P. Kumar, I. Dutta, and M.S. Bakir, J. Electron. Mater. 41, 322 (2012).

I. De Wolf, K. Croes, O.V. Pedreira, R. Labie, A. Redolfi, M. Van De Peer, K. Vanstreels, C. Okoro, B. Vandevelde, and E. Beynea, Microelectron. Reliab. 51, 1856 (2011).

C. Okoro, C. Huyghebaert, J. V. Olmen, R. Labie, K. Lambrinou, B. Vandevelde, E. Beyne, and D. Vandepitte, in AIP Conference Proceedings (2010), pp. 214–220.

S.K. Ryu, Q. Zhao, M. Hecker, H.Y. Son, K.Y. Byun, J. Im, P.S. Ho, and R. Huang, J. Appl. Phys. 111, 063513 (2012).

M. Hecker, L. Zhu, C. Georgi, I. Zienert, J. Rinderknecht, H. Geisler, and E. Zschech, Front. Charact. Metrol. Nanoelectron. 931, 435 (2007).

Acknowledgements

The authors thank the support of Beijing Nova Program (Z161100004916155) and General program of science and technology of Beijing Municipal Education Commission (SQKM201610005024).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, X., Ma, L., Wang, Y. et al. Effect of Thermal Mechanical Behaviors of Cu on Stress Distribution in Cu-Filled Through-Silicon Vias Under Heat Treatment. J. Electron. Mater. 47, 142–147 (2018). https://doi.org/10.1007/s11664-017-5885-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5885-y