Abstract

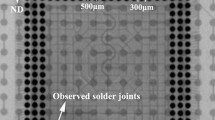

In order to investigate subgrain rotation behavior in the recrystallized region of lead-free solder joints, a ball grid array (BGA) specimen with a cross-sectioned edge row was thermally shocked. Electron backscattered diffraction (EBSD) was used to obtain the microstructure and orientations of Sn grains or subgrains in as-reflowed and thermally shocked conditions. Orientation imaging microscopy (OIM) showed that several subgrains were formed at the tilted twin grain boundaries, near the chip side and near the printed circuit board (PCB) side after 200 thermal shocks due to a highly mismatched coefficient of thermal expansion (CTE) of twin grains. Also, subgrains formed at the chip side and PCB side in the solder joint were selected to research the grain rotation behavior in lead-free solder joints. The analysis of subgrain rotation also indicated that the rotation behavior of subgrains was different between the chip side and PCB side. It was closely related with the large different crystal orientations between the chip side and PCB side. Furthermore, electron backscattered patterns (EBSPs) at several parts of the joint were not obtained after 300 thermal shocks due to the serious deformation caused by mismatched CTE during thermal shock. But 4 subgrains were selected and compared with that of the initial state and 200-thermal shock conditions. The results showed that the subgrains at the chip side were also rotated around the Sn [101] and [001] axes and the subgrains at the PCB side were also rotated around the Sn [100] axis, which indicated a continuous process of subgrain rotation.

Similar content being viewed by others

References

Y.S. Lai, H.M. Tong, and K.N. Tu, Microelectron. Reliab. 49, 3 (2009).

L. Qu, N. Zhao, H.T. Ma, and H.J. Zhao, J. Appl. Phys. 115, 20 (2014).

H.T. Ma and T.K. Lee, IEEE Trans. Compon. Packag. Manuf. Technol. 3, 1 (2013).

T.T. Mattila, J. Hokka, and M. Paulasto-Krockel, J. Electron. Mater. 43, 11 (2014).

L. Yin, L. Wentlent, and L.L. Yang, J. Electron. Mater. 41, 2 (2012).

A.U. Telang, T.R. Bieler, J.P. Lucas, K.N. Subramanian, L.R. Lehman, and Y. Xing, J. Electron. Mater. 33, 12 (2004).

S. Terashima, K. Takahama, M. Nozaki, and M. Tanaka, Mater. Trans. 45, 1383 (2004).

T.K. Lee, C.U. Kim, and T.R. Bieler, J. Electron. Mater. 43, 69 (2014).

P. Lall, S. Shantaram, J. Suhling, and D. Locker, J. Electron. Packag. 137, 011010–011011 (2015).

M.A. Matin, W.P. Vellinga, and M.G.D. Geers, Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 445, 73 (2007).

B.T. Zhou, T.R. Bieler, T.K. Lee, and W.J. Liu, J. Electron. Mater. 42, 319 (2013).

J. Shen, D.J. Zhai, Z.M. Cao, M.L. Zhao, and Y.Y. Pu, J. Electron. Mater. 43, 2 (2014).

B.T. Zhou, G. Muralidharan, K. Kurumadalli, C.M. Parish, S. Leslie, and T.R. Bieler, J. Electron. Mater. 43, 1 (2014).

R.T. Gao, X.Y. Li, and Y.X. Zhu, J. Mater. Sci. Mater. Electron. 26, 4 (2015).

B.T. Zhou, Q. Zhou, T.R. Bieler, and T.K. Lee, J. Electron. Mater. 44, 895 (2015).

A. Mayyas, A. Qasaimeh, P. Borgesen, and M. Meilunas, Microelectron. Reliab. 54, 2 (2014).

B. Zhou, T.R. Bieler, T.K. Lee, and K.C. Liu, J. Electron. Mater. 38, 2702 (2009).

T.R. Bieler and A.U. Telang, J. Electron. Mater. 38, 2712 (2009).

H. Shen, W. Zhu, Y. Li, N. Tamura, and K. Chen, Sci. Rep. 6, 24418 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, J., Tan, S. & Guo, F. Study on Subgrain Rotation Behavior at Different Interfaces of a Solder Joint During Thermal Shock. J. Electron. Mater. 45, 6086–6094 (2016). https://doi.org/10.1007/s11664-016-4965-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4965-8