Abstract

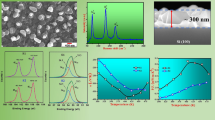

A simple, efficient and rapid brush-printing method has been developed for preparation of n-type Bi2Te2.7Se0.3 films approximately 100–150 μm thick. X-ray diffraction, scanning electron microscopy, electron probe microanalysis, and four-point probe measurements were used to characterize the crystal structure, composition, microstructure, and electrical properties of the films. The results showed that all the n-type Bi2Te2.7Se0.3 thick films were composed of single-phase Bi2Te2.7Se0.3; the grains in the films were randomly distributed in the low-temperature-annealed samples and predominantly oriented along the (00l) plane in samples annealed at temperatures >673 K. σ and the absolute value of α first increased substantially with increasing the annealing temperature in the range 573–673 K then decreased when the annealing temperature was increased further. The dependence of σ and α on annealing temperature may be reasonably explained on the basis of the change in the microstructure induced by annealing. The performance of a prototype cooling device containing n-type Bi2Te2.7Se0.3 thick films was evaluated for temperature differences produced by use of different DC currents.

Similar content being viewed by others

References

J.H. Yang and T. Caillat, MRS Bull. 31, 224 (2006).

L.E. Bell, Science 321, 1457 (2008).

D. Madan, A. Chen, P.K. Wright, and J.W. Evans, J. Appl. Phys. 109, 034904 (2011).

B.C. Sales, Science 295, 1248 (2002).

L.M. Goncalves, P. Alpuim, G. Min, D.M. Rowe, C. Couto, and J.H. Correia, Vacuum 82, 1499 (2008).

M. Takashiri, T. Shirakawa, K. Miyazaki, and H. Tsukamoto, Sen. Actuators A 138, 329 (2007).

H.L. Zou, D.M. Rowe, and G. Min, J. Cryst. Growth 222, 82 (2001).

H. Huang, W.L. Luan, and S.T. Tu, Thin Solid Films 517, 3731 (2009).

M. Tan, Y. Deng, Y. Wang, Z.W. Zhang, B.W. Luo, and Z. Lin, Thin Solid Films 548, 526 (2013).

A. Bailini, F. Donati, M. Zamboni, V. Russo, M. Passoni, C.S. Casari, A.L. Bassi, and C.E. Bottani, Appl. Surf. Sci. 254, 1249 (2007).

T. Sun, M.K. Samani, N. Khosravian, K.M. Ang, Q.Y. Yan, B.K. Tay, and H.H. Hng, Nano Energy 8, 223 (2014).

N. Peranio, M. Winkler, D. Bessas, Z. Aabdin, J. König, H. Böttner, R.P. Hermann, and O. Eibl, J. Alloy Compd. 521, 163 (2012).

Z. Aabdin, N. Peranio, M. Winkler, D. Bessas, J. König, R.P. Hermann, H. Böttner, and O. Eibl, J. Electron. Mater. 41, 1493 (2012).

S.H. Li, H.M.A. Soliman, J. Zhou, M.S. Toprak, M. Muhammed, D. Platzek, P. Ziolkowski, and E. Müller, Chem. Mater. 20, 4403 (2008).

H.M.A. Soliman and A.B. Kashyout, Engineering 3, 659 (2011).

D. Madan, Z.Q. Wang, A. Chen, R. Winslow, P.K. Wright, and J.W. Evans, Appl. Phys. Lett. 104, 013902 (2014).

K.T. Kim and G.H. Ha, J. Nanosci. Nanotechnol. 12, 1577 (2012).

J. Weber, K. Potje-Kamloth, F. Haase, P. Detemple, F. Volklein, and T. Doll, Sens. Actuators A 132, 325 (2006).

G. Liu, W.Y. Zhao, H.Y. Zhou, P. Wei, J. Yu, D.G. Tang, and Q.J. Zhang, J. Electron. Mater. 41, 1376 (2011).

H.Y. Zhou, W.Y. Zhao, G. Liu, H. Cheng, and Q.J. Zhang, J. Electron. Mater. 41, 1436 (2013).

X.A. Fan, J.Y. Yang, R.G. Chen, H.S. Yun, W. Zhu, S.Q. Bao, and X.K. Duan, J. Phys. D 39, 740 (2006).

J. Jiang, L. Chen, S. Bai, Q. Yao, and Q. Wang, Mater. Sci. Eng. B 117, 334 (2005).

W.S. Liu, Q.Y. Zhang, Y.C. Lan, S. Chen, X. Yan, Q. Zhang, H. Wang, D.Z. Wang, G. Chen, and Z.F. Ren, Adv. Energy Mater. 1, 577 (2011).

L.P. Hu, T.J. Zhu, X.H. Liu, and X.B. Zhao, Adv. Funct. Mater. 24, 5211 (2014).

D. Li, R.R. Sun, and X.Y. Qin, Intermetallics 19, 2002 (2011).

D.H. Kim, C. Kim, K. Je, G.H. Ha, and H. Kim, Acta. Mater. 59, 4957 (2011).

D.B. Hyun, J.S. Hwang, and J.D. Shim, J. Mater. Sci. 36, 1285 (2001).

W.E. Bies, R.J. Radtke, H. Ehrenreich, and E. Runge, Phys. Rev. B 65, 085208 (2002).

J.R. Sootsman, D.Y. Chung, and M.G. Kanatzidis, Angew. Chem. Int. Ed. 48, 8616 (2009).

Z. Zhang, Y. Wang, Y. Deng, and Y. Xu, Solid State Commun. 151, 1520 (2011).

Z.Y. Lu, M. Layani, X.X. Zhao, L.P. Tan, T. Sun, S.F. Fan, Q.Y. Yan, S. Magdassi, and H.H. Hng, Small 10, 3551 (2014).

W. Seifert, M. Ueltzen, and E. Müller, Phys. Status Solidi A 194, 277 (2002).

M.J. Huang, P.K. Chou, and M.C. Lin, Sens. Actuators A 126, 122 (2006).

Acknowledgements

This work was supported by the National Basic Research Program of China (973-program) under Project No. 2013CB632505 and the National Natural Science Foundation of China (No. 11274248).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, X., Zhao, Wy., Zhou, Hy. et al. Fabrication and Optimization of Brush-Printed n-type Bi2Te3 Thick Films for Thermoelectric Cooling Devices. J. Electron. Mater. 45, 1328–1335 (2016). https://doi.org/10.1007/s11664-015-4027-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-4027-7