Abstract

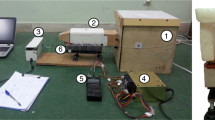

The optimization of thermoelectric air conditioners (TEAC) has been a challenging topic due to the multitude of variables that must be considered. The present work discusses an experimental validation of the optimum design for an automotive air-to-air TEAC. The TEAC optimum design was obtained by using a new optimal design method with dimensional analysis that has been recently developed. The design constraints were obtained through a previous analytical study on the same topic. To simplify the problem, a unit cell representing the entire TEAC system was analytically simulated and experimentally tested. Moreover, commercial TEC modules and heat sinks were selected and tested based on the analytical optimum design results.

Similar content being viewed by others

Abbreviations

- A e :

-

Cross-sectional area of thermoelement (mm2)

- A b :

-

Total base area of thermoelectric air conditioner (mm2)

- A c :

-

Total fin surface area of cold-side heat sink (mm2)

- A h :

-

Total fin surface area of hot-side heat sink (mm2)

- A UC :

-

Unit cell base area (mm2)

- COP:

-

Coefficient of performance

- c p :

-

Specific heat (J/kg K)

- G e :

-

Thermocouple geometric ratio

- H :

-

Total height of thermoelectric air conditioner (mm)

- h :

-

Heat transfer coefficient of the fluid (W/m2 K)

- I :

-

Electric current (A)

- L :

-

Total length of thermoelectric air conditioner (mm)

- L c :

-

Unit cell cold-side length (mm)

- L e :

-

Length of thermoelement (mm)

- L h :

-

Unit cell hot-side length (mm)

- k :

-

Thermoelement thermal conductivity (W/m K), k = k p + k n

- n :

-

Number of thermocouples

- \( n_{\rm{c}} \) :

-

Number of fins for the cold-side heat sink

- \( n_{\rm{h}} \) :

-

Number of fins for the hot-side heat sink

- N k :

-

Dimensionless thermal conductance, N k = n(A e k/L e)/η h h h A h

- N h :

-

Dimensionless convection, N h = η c h c A c/η h h h A h

- N I :

-

Dimensionless current, N I = αI/(A e k/L e)

- Q c :

-

Total cooling power from thermoelectric air conditioner (W)

- P in :

-

Total input power for thermoelectric air conditioner (W)

- \( {\hbox{PD}} \) :

-

Power density (W/cm2)

- R :

-

Electrical resistance of a thermocouple (Ω)

- Re:

-

Fluid Reynolds number

- T c :

-

Cold-junction temperature (°C)

- T h :

-

Hot-junction temperature (°C)

- T ∞c :

-

Cold-fluid temperature (°C)

- T ∞h :

-

Hot-fluid temperature (°C)

- ΔT :

-

Thermoelectric temperature different (°C)

- ΔT cooling :

-

Cold air temperature inlet–outlet (°C)

- t c :

-

Cold-side air fin thickness

- t h :

-

Hot-side air fin thickness

- V h :

-

Hot fluid volume flow rate (L/min for liquid, CFM for air)

- W :

-

Total width of thermoelectric air conditioner (mm)

- Z :

-

Figure of merit (1/K) = α 2/ρk

- z c :

-

Fin spacing for the cold-side air (mm)

- z h :

-

Fin spacing for the hot-side air (mm)

- α :

-

Seebeck coefficient (V/K), α = α p − α n

- ρ :

-

Electrical resistivity (Ω cm), ρ = ρ p + ρ n

- φ :

-

Aluminum block thermal resistance (K/W)

- η c :

-

Fin efficiency of cold-side heat sink

- η h :

-

Fin efficiency of hot-side heat sink

- c:

-

Cold

- e:

-

Thermoelement

- h:

-

Hot

- p :

-

p-Type element

- n :

-

n-Type element

- m:

-

Measured

- opt.:

-

Optimal quantity

- UC:

-

Unit cell

- *:

-

Dimensionless

References

C.B. Vining, Nat. Mater. 8, 83 (2009).

J. Fairbanks, Vehicular thermoelectric applications session DEER 2009, U.S. Department of Energy, 05 08 2009. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/deer_2009/session7/deer09_fairbanks.pdf. Accessed 06 Nov 2013.

R. Gonzalez, Automotive thermoelectric HVAC development and demonstration project, California Energy Commission, 10 2010. http://www.energy.ca.gov/2010publications/CEC-500-2010-FS/CEC-500-2010-FS-018.PDF. Accessed 06 Nov 2013.

C.W. Maranville, Thermoelectric HVAC and Thermal Comfort Enablers for Light-Duty Vehicle Applications, United States Department of Energy, 18 05 2012. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2012/adv_combustion/ace047_maranville_2012_o.pdf. Accessed 06 Nov 2013.

N.C. Strupp, N.C. Lemke, J. Koehler, and C.S. Junior, J. Electron. Mater. 38, 1093 (2009).

D. Crane, J. LaGrandeur, D. Wang, Design and analysis of a thermoelectric hvac system for passenger vehicles, SAE Int., Vols. 2010-01-0807, 2010.

M.S. Raut and D.V. Walke, IJEST 4, 2381 (2012).

C.-Y. Hsu, S.-L. Li, C.-K. Liu, R.-M. Tain, H.-C. Chien, S.-F. Hsu, C.-M. Tzeng, M.-J. Dai, H.-S. Chu, J.-D. Hwang, Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), 2011 6th International (Taipei, 2011).

J. Schneider, L. Chaney, T. Barnhart, J.P. Heremans, C.W. Maranville, Improving efficiency of a vehicle HVAC system with comfort modeling, zonal design, and thermoelectric devices, United States Department of Energy, 18 10 2012. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/deer_2012/Thursday/presentations/deer12_maranville.pdf. Accessed 06 Nov 2013.

D. Thomas, G. Roumayah, T. Barnhart, Development of a Thermoelectric Device for an Automotive Zonal HVAC System, United States Department of Energy, 20 03 2011. https://www1.eere.energy.gov/vehiclesandfuels/pdfs/thermoelectrics_app_2012/Tuesday/barnhart.pdf. Accessed 06 Nov 2013.

A. Attar, H. Lee, and S. Weera, J. Electron. Mater. 43, 2179 (2014).

H. Lee, Appl. Energy, 115 (2013).

H. Lee, Thermal Design: Heat Sinks, Thermoelectrics, Heat Pipes, Compact Heat Exchangers, and Solar Cells (Hoboken: Wiley, 2010).

C. Fah and W. Zhimin, Electronic Packaging Technology Conference (1997).

S.L.L. Weera and H. Lee (Master’s thesis, Western Michigan University, Kalamazoo, MI, 2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Attar, A., Lee, H. & Weera, S. Experimental Validation of the Optimum Design of an Automotive Air-to-Air Thermoelectric Air Conditioner (TEAC). J. Electron. Mater. 44, 2177–2185 (2015). https://doi.org/10.1007/s11664-015-3750-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3750-4