Abstract

Copper slag is a residue from the copper smelting process that not only takes up large amounts of space, but also contains harmful elements that can cause environmental pollution. In this paper, zinc in copper slag is sulfide-roasted using pyrite as a vulcanizing agent and anthracite and K2CO3 as additives, thus leaving zinc in the slag mainly in the form of ZnS. After sulfurization roasting, the slag can be stripped of Zn by flotation, and the remaining iron can be further applied in the blast furnace ironmaking process. The effects of temperature, holding time, pyrite addition, and K2CO3 addition on the Zn sulfation rate were investigated. The results showed that when pyrite, anthracite, and K2CO3 were added to the slag in amounts of 35, 2, and 10 pct of the slag’s original mass, respectively, the total Zn in the slag was 3.16 pct, and its sulfuration rate was 83.5 pct. When pyrite was used to sulfide and dezincify copper bottom-blown smelting slag, the ZnO content in the slag was effectively reduced in preparation for subsequent ironmaking after flotation. This approach not only solves the problem of large piles of copper slag that cannot be fully utilized, but also alleviates the current shortage of iron ore in China.

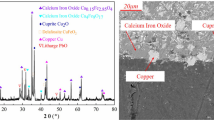

Graphical Abstract

Similar content being viewed by others

References

A. Potysz, E.D. van Hullebusch, J. Kierczak, M. Grybos, P.N.L. Lens, and G. Guibaud: Crit. Rev. Environ. Sci. Technol., 2015, vol. 45, pp. 2424–88.

B. Zhang, L. Niu, T. Zhang, Z. Li, D. Zhang, and C. Zheng: ISIJ Int., 2017, vol. 57, pp. 775–81.

S. Çoruh, O.N. Ergun, and T.-W. Cheng: Waste Manag. Res., 2006, vol. 24, pp. 234–41.

I. Alp, H. Deveci, and H. Süngün: J. Hazard. Mater., 2008, vol. 159, pp. 390–95.

D. Durinck, F. Engström, S. Arnout, J. Heulens, P.T. Jones, B. Björkman, B. Blanpain, and P. Wollants: Resour. Conserv. Recycl., 2008, vol. 52, pp. 1121–31.

Y. Li, I. Perederiy, and V.G. Papangelakis: J. Hazard. Mater., 2008, vol. 152, pp. 607–15.

B. Zhang, T. Zhang, and Z. Dou: Minerals, 2022, vol. 12, p. 496. https://doi.org/10.3390/min12050496.

A.D. Chandio, I.A. Channa, A.A. Shaikh, S. Madad, S.B.H. Rizvi, A.A. Shah, J. Ashfaq, M. Ali Shar, and A. Alhazaa: Metals (Basel), 2023, vol. 13, p. 296.

G. Shi, Y. Liao, B. Su, Y. Zhang, W. Wang, and J. Xi: Purif. Technol., 2020, vol. 241, p. 116699. https://doi.org/10.1016/j.seppur.2020.116699.

R. Mao, F. Wang, Y. Xu, K. Ren, and G. Wang: Metall. Res. Technol., 2021, vol. 118, p. 602.

D. Zhu, S. Li, J. Pan, C. Yang, and B. Shi: Powder Technol., 2019, vol. 342, pp. 864–72.

L. Xu, J.-G. Ku, C.-J. Lin, and X.-Y. Liu: Progress in Iron Recovery from Copper Slags.

X. K. Shang, Z. Y. Lan, Q. F. Zhang, and T.T. Li: in Advanced Materials Research, vol. 926–930, Trans Tech Publications, 2014, pp. 4197–4200.

A.A. Lykasov, G.M. Ryss, D.G. Sharafutdinov, and AYu. Pogodin: Steel Transl., 2016, vol. 46, pp. 609–13.

K.Q. Li, S. Ping, H.Y. Wang, and W. Ni: Int. J. Miner. Metall. Mater., 2013, vol. 20, pp. 1035–41.

Y.X. Zheng, J.F. Lv, H. Wang, S.M. Wen, and J. Pang: Sci. Rep., 2018, vol. 2, p. 89. https://doi.org/10.1038/s41598-018-26229-3.

Y. Li, J. Wang, C. Wei, C.X. Liu, J.B. Jiang, and F. Wang: Miner. Eng., 2010, vol. 23, pp. 563–66.

W. Liu, L. Zhu, J. Han, F. Jiao, and W. Qin: Sci. Rep., 2018, https://doi.org/10.1038/s41598-018-27968-z.

X. Min, B. Zhou, Y. Ke, L. Chai, K. Xue, C. Zhang, Z. Zhao, and C. Shen: Appl. Surf. Sci., 2016, vol. 371, pp. 67–73.

C. Pickles: Sep. Purif. Technol., 2008, vol. 59, pp. 115–28.

A. Badarau and C. Dennison: Proc. Natl. Acad. Sci., 2011, vol. 108, pp. 13007–12.

M. Shevchenko and E. Jak: Calphad, 2020, https://doi.org/10.1016/j.calphad.2020.101800.

J. Jeon and D. Lindberg: Ceram. Int., 2023, vol. 49, pp. 12736–44.

P.-C. Lin, C.C. Hua, and T.-C. Lee: J. Solid State Chem., 2012, vol. 194, pp. 282–85.

K. Han, I. Ohnuma, K. Okuda, and R. Kainuma: J. Alloys Compd., 2018, vol. 737, pp. 490–504.

S. Kumar, M. Kumar, and A. Singh: Contemp. Phys., 2021, vol. 62, pp. 144–64.

X. Guo, B. Zhang, Q. Wang, Z. Li, and Q. Tian: JOM, 2021, vol. 73, pp. 1861–70.

Q. Zhao, J. Lin, H. Huang, Z. Xie, and Y. Xiao: Energy Rep., 2022, vol. 8, pp. 129–36.

D. Sergeev, E. Yazhenskikh, P. Haseli, M. Liu, M. Ziegner, F. Bruno, and M. Müller: Calphad, 2020, vol. 71, p. 101992.

Acknowledgments

Financial support for this study was supplied from the National Natural Science Foundation of China (Project Nos. 51764035) and the Natural Science Foundation of Yunnan province (Project Nos. 2018FB089).

Conflict of interest

The authors declare that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Zhang, H., Li, B. et al. Sulfurization Roasting of Copper Bottom-Blown Slag for Zinc Removal Using Pyrite. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03093-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03093-3