Abstract

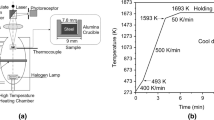

In this study, the dissolution, collision, aggregation, and separation behaviors of nitride inclusions at the melt interface of GH4169 nickel-based superalloy were investigated via thermodynamic calculations combined with in situ observation via high-temperature confocal laser scanning microscope (CLSM). The results showed that the nitride inclusions were able to dissolve completely during the alloy melting process, and boundary layer diffusion was the limiting factor for dissolution. Nitride inclusions from the remelting process were reprecipitated during solidification. As the melt temperature increased, the degree of dissolution of the inclusions increased, and the dissolution rate of the inclusions increased. Second, the results of in situ observation by CLSM showed that nitride inclusions were more likely to aggregate with oxide inclusions, that separation may still occur between nitride inclusions after aggregation. The attraction of nitride–oxide inclusions was greater than that of nitride–nitride inclusions. The ability of the inclusions in the collision zone to aggregate together in contact depends on the interaction forces between the inclusions. The calculation results showed that the cavity bridge force was much greater than the capillary force and van der Waals force, which were the main forces leading to aggregation between the inclusions. Once a stable cavity bridge was formed between the inclusions, the aggregated inclusions no longer separated. In contrast, if cavity bridges formed between inclusions were substable, then fluctuations in the alloy melt would cause the substable structure to rupture, leading to the separation of inclusions.

Similar content being viewed by others

References

T.A. Ivanoff, T.J. Watt, and E.M. Taleff: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 700–15.

J.H. Du, X.D. Lv, J.X. Dong, W.R. Sun, Z.N. Bi, G.P. Zhao, Q. Deng, C.Y. Cui, H.P. Ma, and B.J. Zhang: Acta Metall. Sin., 2019, vol. 55, pp. 1115–32.

K.S. Chan: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 1148–62.

J. Jiang, J. Yang, T. Zhang, J. Zou, Y. Wang, F.P.E. Dunne, and T.B. Britton: Acta Mater., 2016, vol. 117, pp. 333–44.

G.M. Owolabi and H.A. Whitworth: J. Mater. Sci. Technol., 2014, vol. 30, pp. 203–12.

X.C. Chen, C.B. Shi, H.J. Guo, F. Wang, H. Ren, and D. Feng: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 1596–1607.

J. Wang, L.Z. Wang, J.Q. Li, C.Y. Chen, S.F. Yang, and X. Li: J. Alloys Compd., 2022, vol. 906, p. 164281.

L. Yang and G.G. Cheng: Int. J. Miner. Metall. Mater. B, 2017, vol. 24, pp. 869–75.

X.Y. Gao, L. Zhang, Y.F. Luan, X.W. Chen, and X.H. Qu: JOM, 2020, vol. 72, pp. 3247–55.

H.B. Yin, H. Shibata, T. Emi, and M. Suzuki: ISIJ Int., 1997, vol. 37, pp. 936–45.

K. Nakajima and S. Mizoguchi: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 629–41.

J. Wikström, K. Nakajima, H. Shibata, A. Tilliander, and P. Jönsson: Mater. Sci. Eng. A, 2008, vol. 495, pp. 316–19.

S. Kimura, K. Nakajima, and S. Mizoguchi: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 79–85.

C.J. Xuan, A.V. Karasev, P.G. Jönsson, and K. Nakajima: Steel Res. INT., 2017, vol. 88, pp. 132–41.

K. Sasai: ISIJ Int., 2015, vol. 54, pp. 2780–89.

K. Sasai: ISIJ Int., 2016, vol. 56, pp. 1013–22.

Q.R. Tian, G.C. Wang, D.L. Shang, H. Lei, X.H. Yuan, Q. Wang, and J. Li: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 3137–50.

K. Sasai: ISIJ Int., 2020, vol. 60, pp. 409–18.

W.Z. Mu and C.J. Xuan: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2694–2705.

Y.T. Li, L.Z. Wang, J.Q. Li, S.F. Yang, C.Y. Chen, C.G. Li, and X. Li: ISIJ Int., 2020, vol. 61, pp. 753–62.

J.X. Chen: Manual of Chart and Data in Common Use of Steel Making, 2nd ed. Metallurgical Industry Press, Beijing, 2010, pp. 657–846.

B. Ozturk, R. Matway, and R.J. Fruehan: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 563–67.

E.B. Chen, S.J. Wang, Y.C. Dong, B.G. Wu, and Y. Zhou: J. Iron. Steel Res. Int., 2007, vol. 14, pp. 21–24.

X.L. Guo, J.B. Yu, X.F. Li, Y. Hou, and Z.M. Ren: Ironmak. Steelmak., 2018, vol. 45(3), pp. 215–23.

R.F. Abdulrahman and A. Hendry: Metall. Mater. Trans. B, 2001, vol. 32(6), pp. 1103–12.

T. Hong and T. Debroy: Ironmak. Steelmak., 2013, vol. 28, pp. 450–54.

M.J. Whelan: Metal Sci. J., 1969, vol. 3, pp. 95–97.

K.H. Sandhage and G.J. Yurek: J. Am. Ceram. Soc., 1990, vol. 73, pp. 3643–49.

X. Yin, Y. Yang, D. Li, Y. Sun, X. Deng, M. Barati, and A. Mclean: Ironmak. Steelmak., 2017, vol. 44, pp. 140–51.

T. Toh, H. Yamamura, H. Kondo, M. Wakoh, S. Shimasaki, and S. Taniguchi: ISIJ Int., 2007, vol. 47, pp. 1625–32.

V.N. Paunov, P.A. Kralchevsky, N.D. Denkov, and K. Nagayama: J. Colloid Interf. Sci., 1993, vol. 157, pp. 100–12.

D.Y.C. Chan, J.D. Henry, and L.R. White: J. Colloid Interf. Sci., 1981, vol. 79, pp. 410–18.

S. Taniguchi, A. Kikuchi, T. Ise, and N. Shoji: ISIJ Int., 1996, vol. 36, pp. S117–20.

V.V. Yaminsky, V.S. Yushchenko, E.A. Amelina, and E.D. Shchukin: J. Colloid Interf. Sci., 1983, vol. 96, pp. 301–06.

V.S. Yushchenko, V.V. Yaminsky, and E.D. Shchukin: J. Colloid Interf. Sci., 1983, vol. 96, pp. 307–14.

K. Sasai and Y. Mizukami: ISIJ Int., 2001, vol. 41, pp. 1331–39.

K.L. Chen, D.Y. Wang, D. Hou, T.P. Qu, J. Tian, and H.H. Wang: ISIJ Int., 2019, vol. 59, pp. 1735–43.

H.J. Duan, Y. Ren, and L.F. Zhang: Chem. Eng. Sci., 2018, vol. 196, pp. 14–24.

J.J. Wang, L.F. Zhang, Y.X. Zhang, Q. Ren, and H.J. Duan: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2831–36.

S.K. Michelic and C. Bernhard: Scanning, 2017, vol. 2017, p. 2326750.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 52074030 and 52104318).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, T., Yang, S., Liu, W. et al. In Situ Observation of the Dissolution, Collision, and Aggregation Behavior of Nitride Inclusions in GH4169 Nickel-Based Superalloy. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03027-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03027-z