Abstract

Inclusions in metallurgical grade silicon (MG-Si) can significantly degrade the quality and performance of silicon materials. Thus, it is essential to implement effective measures to control and minimize their presence. This study investigates the morphology, distribution, and microstructural evolution of inclusions in silicon by introducing varying amounts of Sn. The changes in Fe content at different positions in silicon ingots before and after Sn refining were examined. The study demonstrates that Sn refining can reduce the number of inclusions at the bottom of silicon ingots by up to 71.3 pct. The morphology of inclusions undergoes a transition from fine filaments and sporadic dots to block-like formations, ordered short rods, and dots. There is an upward migration of Fe in the vertical direction, leading to a reduction in Fe content at the bottom from 0.61 to 0.25 pct, representing a significant decrease of 59.03 pct. These findings suggest that the addition of Sn to silicon can effectively remove Fe impurities. Additionally, the incorporation of Sn refining enables a reduction in the formation of the Si7Al8Fe5 phase and enhances the selectivity of the organosilicon monomer synthesis process. Remarkably, the partial substitution of Ti by Al leads to the formation of the FeSi2Ti(Al) phase. However, Ca tends to concentrate in Sn and remains unaffected by the Sn content. These empirical findings offer experimental evidence for effectively reducing and controlling the quantity and morphology of inclusions in MG-Si, thereby significantly enhancing the quality of MG-Si production.

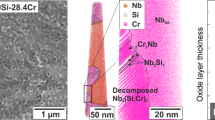

Graphical Abstract

Similar content being viewed by others

References

C. Ramírez-Márquez, M.V. Otero, J.A. Vázquez-Castillo, M. Martín, and J.G. Segovia-Hernández: J. Clean. Prod., 2018, vol. 170, pp. 1579–93.

W.O. Filtvedt, M. Javidi, A. Holt, M.C. Melaaen, E. Marstein, H. Tathgar, and P.A. Ramachandran: Sol. Energy Mater. Sol. Cells, 2010, vol. 94, pp. 1980–95.

H. Sasaki, Y. Kobashi, T. Nagai, and M. Maeda: Adv. Mater. Sci. Eng., 2013, vol. 2013, pp. 1–8.

H. Chen, K. Morita, X. Ma, Z. Chen, and Y. Wang: Sol. Energy Mater. Sol. Cells, 2019, vol. 203, 110169.

X. Yang, W. Ma, G. Lv, K. Wei, D. Chen, S. Li, D. Zheng, and Z. Chen: Appl. Therm. Eng., 2016, vol. 106, pp. 890–98.

S. Wen, Y. Tan, T. Yuan, P. Li, M. Forzan, D. Jiang, and F. Dughiero: Vacuum, 2017, vol. 145, pp. 251–57.

X. Deng, L. Zhou, K. Wei, and W. Ma: Vacuum, 2023, vol. 207, 111581.

A. Hoseinpur and J. Safarian: Vacuum, 2021, vol. 184, 109924.

J. Wu, Y. Li, W. Ma, K. Liu, K. Wei, K. Xie, B. Yang, and Y. Dai: Silicon, 2014, vol. 6, pp. 79–85.

J. Wu, D. Yang, M. Xu, W. Ma, Q. Zhou, Z. Xia, Y. Lei, K. Wei, S. Li, Z. Chen, and K. Xie: Sep. Purif. Rev., 2020, vol. 49, pp. 68–88.

Z. Xia, J. Wu, W. Ma, Y. Lei, K. Wei, and Y. Dai: Sep. Purif. Technol., 2017, vol. 187, pp. 25–33.

Q. He, J. Wen, G. Yang, F. Xu, M. Xu, Z. Chen, J. Wu, and W. Ma: Silicon, 2023, https://doi.org/10.1007/s12633-023-02453-z.

Y. Lei, W. Ma, J. Wu, K. Wei, G. Lv, S. Li, and K. Morita: Mater. Sci. Semicond. Process., 2018, vol. 88, pp. 97–102.

W. Yu, Y. Xue, J. Mei, X. Zhou, M. Xiong, and S. Zhang: J. Alloy Compd., 2019, vol. 805, pp. 198–204.

Z. Ding, W. Ma, K. Wei, J. Wu, Y. Zhou, and K. Xie: J. Non-Cryst. Solids, 2012, vol. 358, pp. 2708–12.

L. Huang, H. Lai, C. Lu, M. Fang, W. Ma, P. Xing, J. Li, and X. Luo: Hydrometallurgy, 2016, vol. 161, pp. 14–21.

H. Lu, K. Wei, W. Ma, K. Xie, J. Wu, and Y. Lei: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2768–80.

Margaria T J, Anglezio C, and Servant C: Proc. 6th Int. Ferroalloys Congr. INFACON, 1992, vol. 6, pp. 209–14.

J.C. Anglézio, C. Servant, and F. Dubrous: J. Mater. Res., 1990, vol. 5, pp. 1894–99.

S. Li, X. Long, L. Chen, and W. Qiu: J. Mater. Res. Technol., 2023, vol. 22, pp. 1911–23.

S. Li, X. Deng, J. Wen, K. Wei, and W. Ma: Intermetallics, 2021, vol. 128, 106987.

Y.V. Meteleva-Fischer, Y. Yang, R. Boom, B. Kraaijveld, and H. Kuntzel: Intermetallics, 2012, vol. 25, pp. 9–17.

Z. Shan, J. Wen, G. Yang, F. Xu, J. Wu, K. Wei, and W. Ma: Silicon, 2023, vol. 15, pp. 4889–96.

Y. Li, Y. Tan, P. Cao, J. Li, P. Jia, and Y. Liu: Mater. Res. Innov., 2015, vol. 19, pp. 81–85.

Y. Ren, S. Ueda, and K. Morita: ACS Sustain. Chem. Eng., 2019, vol. 7, pp. 20107–13.

Y. Liu, S. Wang, S. Jiang, X. Wang, J. Kong, P. Xing, Y. Zhuang, and X. Luo: J. Mater. Res. Technol., 2019, vol. 8, pp. 4470–76.

R.H. Hopkins and A. Rohatgi: J. Cryst. Growth, 1986, vol. 75, pp. 67–79.

L. Huang, H. Lai, C. Lu, C. Gan, M. Fang, P. Xing, J. Li, and X. Luo: Vacuum, 2016, vol. 129, pp. 38–44.

C.A. Schneider, W.S. Rasband, and K.W. Eliceiri: Nat. Methods, 2012, vol. 9, pp. 671–75.

Y. Zhou, J. Wu, W. Ma, Y. Lei, and Y. Dai: J. Alloy Compd., 2018, vol. 751, pp. 257–65.

Q. He, J. Wu, F. Yang, Y. Zhou, K. Liu, and W. Ma: Sep. Purif. Rev., 2022, vol. 51, pp. 452–67.

F. Yang, J. Wu, and W. Ma: JOM, 2020, vol. 72, pp. 2663–69.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 22078140), the Talent Training Program of Yunnan of China (Nos. 202005AC160041 and KKXY202252002), and the major R&D project of Yunnan of China (No. 202202AG050012).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shan, Z., Wu, J., Wei, K. et al. Effect of Sn Addition on the Evolution of Inclusions in Metallurgical Grade Silicon. Metall Mater Trans B 55, 1014–1026 (2024). https://doi.org/10.1007/s11663-024-03012-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-024-03012-6