Abstract

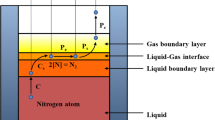

Impurity and non-metallic inclusions control are imperative for the metallurgical quality of superalloys. In this paper, the effect of revert addition on the nitrogen removal and inclusion characteristics of GH4738 superalloy has been investigated. And a multiscale transient model for describing and predicting nitrogen removal from liquid superalloy during the refining process is developed by coupling macroscopic phenomena (including electromagnetic, fluid flow, heat, and mass transfer). A series of experimental data validate the reliability of the model. Results demonstrated that revert addition significantly suppressed the nitrogen removal efficiency and led to more nitrogen residue in the liquid superalloy, contributing to more nitrides or carbonitrides precipitation. The transient model shows that the residual nitrogen in the molten bath is spatially inhomogeneous distributed, in which the mass transfer of nitrogen between the gas–liquid interface is synergistically controlled by chamber pressure, bath temperature, and melt flow pattern. Increasing the refining power enhances the stirring intensity, which accelerates solute transport and facilitates nitrogen removal, but it also leads to a higher refining temperature that thermodynamically inhibits the denitrification reaction. Simulation results show that vacuum refining of revert superalloys by reducing the chamber pressure and increasing the metal bath stirring intensity is beneficial to obtain alloys with low nitrogen content. Considering the inhibitory effect of high temperature and revert addition, adjusting the refining power is recommended to promote nitrogen removal when the proportion of revert is more than 40 pct.

Similar content being viewed by others

References

A. Choudhury: ISIJ Int., 1992, vol. 32, pp. 563–74.

A. Mitchell: Key Eng. Mater., 1992, vol. 77, pp. 177–86.

L.R. Curwick, W.A. Petersen, and J.J. deBarbadillo: Superalloy Scrap-Generation and Recycling. Superalloys, ASM, Metals Park, 1980, pp. 21–30.

A. Mitchell: ISIJ Int., 1992, vol. 32, pp. 557–62.

H.B. Bai, H.R. Zhang, J.F. Weng, B. Kong, and H. Zhang: Mater. Res. Innovat., 2014, vol. 18, pp. S4357-4362.

R.R. Srivastava, M.-S. Kim, J.-C. Lee, M.K. Jha, and B.-S. Kim: J. Mater. Sci., 2014, vol. 49, pp. 4671–86.

H. Tupac-Yupanqui and A. Armani: J. Mater. Eng. Perform., 2021, vol. 30, pp. 1177–87.

Y.H. Yang, J.J. Yu, X.F. Sun, T. Jin, H.R. Guan, and Z.Q. Hu: Mater. Sci. Eng. A, 2012, vol. 532, pp. 6–12.

X.B. Huang, Y. Zhang, and Z.Q. Hu: Metall. Mater. Trans. A, 1999, vol. 30, pp. 1755–61.

X.L. Guo, J.B. Yu, X.F. Li, Y. Hou, and Z.M. Ren: Ironmak. Steelmak., 2016, vol. 45, pp. 215–23.

X. Lu, K. Matsubae, K. Nakajima, S. Nakamura, and T. Nagasaka: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 1785–95.

F.B. Khiavi, M. Soltanieh, and S.M. Abbasi: Vacuum, 2022, vol. 197, p. 110752.

N. Wang, J.G. Gao, S.L. Yang, S.F. Yang, M. Liu, W. Liu, and J.L. Qu: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1474–83.

Y. Li, Y. Tan, X. You, H. Cui, P. Li, Y. Wang, and Q. You: Vacuum, 2021, vol. 189(24–26), p. 110212.

V.V. Sidorov and P.G. Min: Russ. Metall., 2014, vol. 2014, pp. 982–86.

S.F. Yang, P. Zhao, S.L. Yang, W. Liu, J.S. Li, and L. Zheng: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 760–69.

J.H. Cho, J. Martinsson, D. Sichen, and J.H. Park: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 3660–70.

S. Utada, Y. Joh, M. Osawa, et al.: Metall. Mater. Trans. A, 2018, vol. 49, pp. 4029–41.

P. Zhang, W.Y. Gui, M. Jiang, and B.L. Luan: Metall. Mater. Trans. A, 2022, vol. 53, pp. 2259–69.

R. Rahimi, M. N. Ahmadabadi: Proc. EPD Congr. 2012 and TMS 2012 Annual Meeting and Exhibition, Wiley, Orlando, New York, 2012, pp. 417–24.

A. Mitchell and E.A. Loria, eds.: Superalloys 718, 625, 706 and Various Derivatives, TMS, Warrendale, 1994, pp. 109–23.

R. Soundararajan: The Uinversity of British Columnia, 1998.

A. Mitchell: High Temp. Mater. Process., 2005, vol. 24, pp. 101–09.

C. Yuan, J. Guo, G. Li, L. Zhou, Y. Ge, and W. Wang: Chin. J. Nonferrous Met., 2011, vol. 21, pp. 733–46.

M. Zhang, C. Liu, and S. Wang: Adv. Mater. Res., 2012, vol. 538–541, pp. 1187–91.

L. Gong, B. Chen, Y. Yang, Z. Du, and K. Liu: Mater. Sci. Eng. A, 2017, vol. 701, pp. 111–19.

M. Moshtaghi and M. Safyari: Vacuum, 2019, vol. 169, p. 108890.

X. Gao, L. Zhang, X. Chen, Y. Luan, and X. Qu: Mater. Char., 2020, vol. 167, p. 110492.

J. Wang, L. Wang, J. Li, C. Chen, S. Yang, and X. Li: J. Alloys Compd., 2022, vol. 906, p. 164281.

F. Yang, J. Cao, L. Shi, J. Yu, K. Deng, and Z. Ren: ISIJ Int., 2023, vol. 63(3), pp. 436–47.

Q.F. Shu, V.V. Visuri, T. Alatarvas, and T. Fabritius: Metall. Mater. Trans. B, 2022, vol. 53B(4), pp. 2321–33.

A. Umbrashko, E. Baake, B. Nacke, and A. Jakovics: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 831–38.

E. Baake, A. Umbrashko, and A. Jakovics: Steel Res. Int., 2007, vol. 78, pp. 413–18.

M. Ščepanskis, A. Jakovičs, E. Baake, and B. Nacke: Steel Res. Int., 2015, vol. 86, pp. 169–74.

A. Asad, C. Kratzsch, S. Dudczig, C.G. Aneziris, and R. Schwarze: Int. J. Heat Fluid Flow, 2016, vol. 62, pp. 299–312.

A. Asad, K. Bauer, K. Chattopadhyay, and R. Schwarze: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1378–87.

P. Bulinski, J. Smolka, S. Golak, R. Przylucki, M. Palacz, G. Siwiec, B. Melka, and L. Blacha: Int. J. Heat Mass Transf., 2018, vol. 126B, pp. 980–92.

A. Asad and R. Schwarze: Steel Res. Int., 2021, vol. 92, p. 2100122.

A.V. Perminov and I.L. Nikulin: J. Eng. Phys. Thermophys., 2016, vol. 89, pp. 397–409.

Y. Li, Y. Tan, X.G. You, H.Y. Cui, P.T. Li, Y. Wang, and Q.F. You: Vacuum, 2021, vol. 189, p. 110212.

J.P. Niu and Z.Q. Hu: Adv. Mater. Res., 2011, vol. 284–286, pp. 2433–36.

K. Qian, B. Chen, L. Zhang, Z. Du, and K. Liu: Vacuum, 2020, vol. 179, p. 109521.

A. Simkovich: JOM, 1966, vol. 18, pp. 504–12.

F. Takahashi, Y. Momoi, K. Kajikawa, and K. Oikawa: ISIJ Int., 2016, vol. 56, pp. 1746–50.

S. Yang, S. Yang, J. Qu, J. Du, Y. Gu, P. Zhao, and N. Wang: J. Iron Steel Res. Int., 2021, vol. 28, pp. 921–37.

M. Kirpo, A. Jakovics, E. Baake, and B. Nacke: Magnetohydrodynamics, 2006, vol. 42, pp. 207–18.

E.S. Machlin: TMS-AIME, 1960, vol. 218, pp. 314–26.

Acknowledgments

This work was supported by the National Key R&D Program of China (2021YFB3700402), National Natural Science Foundation of China (51974020).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, P., Gao, J., Yang, S. et al. Effect of Revert Addition on the Nitrogen Removal From Liquid Superalloy During Vacuum Induction Melting Process: Experimental and Simulation Studies. Metall Mater Trans B 55, 431–445 (2024). https://doi.org/10.1007/s11663-023-02968-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02968-1