Abstract

An attempt has been made to establish experimentally the temperature along the metastable eutectic in the Fe–C–Si system, down to the invariant three-phase eutectic involving austenite, cementite, and an iron silico-carbide. This was carried out by standard thermal analysis using cups with a coating rich in tellurium that is known to impede graphite growth. It turned out that evaluating the metastable temperature is possible up to a silicon contents of 3.8 wt pct, beyond which the driving force for graphite growth becomes so high that the development of stable eutectic cells can no more be hindered. This is quite unfortunate for melt control on the foundry floor but triggers further study for understanding and describing graphite shape in cast irons.

Similar content being viewed by others

References

A. Regordosa, J. Lacaze, J. Sertucha, M.J. Castro-Roman, U. de la Torre, and O. Dezellus: Int. J. Metalcast., 2022, https://doi.org/10.1007/s40962-022-00799-5.

S. Kante and A. Leineweber: J. Alloy Compds., 2020, vol. 815, p. 152468.

J. Lacaze and B. Sundman: Metall. Trans. A, 1991, vol. 22, pp. 2211–23.

J. Miettinen, V. Ville-Valtteri, and T. Fabritius: Thermodynamic Description of the Fe–Al–Mn–Si–C System for Modelling Solidification of Steels, Oulun yliopisto, Oulu, 2019. http://jultika.oulu.fi/Record/isbn978-952-62-2251-6. Accessed 9 Oct 2022.

H. Nieswaag and A.J. Zuithoff: in 34th International Foundry Congress, 1967, Paper 19.

N. Tsutsumi, M. Imamura, and M. Nakada: The Influence of Tellurium on the Graphite Formation of Cast Iron During Solidification, Report 28 of the Castings Research Laboratory, Waseda University, Tokyo, 1977.

U. de la Torre, A. Regordosa, J. Lacaze, E. Aguado, and J. Sertucha: Materialia, 2023, vol. 27, p. 101665, https://doi.org/10.1016/j.mtla.2022.101665

W. Menk, M.O. Speidel, and R. Döpp: Giessereiforschung, 1992, vol. 44, pp. 66–79.

D.M. Stefanescu: Int. J. Metalcast., 2015, vol. 9, pp. 7–22.

ThermoCalc Softwares and Databases. https://thermocalc.com/products/. Accessed 9 Oct 2022.

W. Oldfield and J.G. Humphreys: BCIRA J., 1962, vol. 10, pp. 315–24.

D. Glover, C.E. Bates, and R. Monroe: AFS Trans., 1982, vol. 90, pp. 745–57.

Acknowledgments

We warmly thank Alexandre Freulon, Cédric Charvillat, and Yannick Thébaut from CIRIMAT for their help in the metallographic preparation, X-ray recordings, and SEM observations.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

See Table AI.

Appendix B

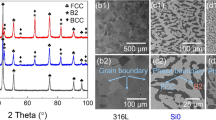

The presence of SC iron silico-carbide was looked for with various means in alloys with high silicon contents. A Bruker D8 Advance diffractometer equipped with a Cu cathode was used in θ–2θ configuration. Records were carried out on various locations of samples 16.5 and 19.5 that all appeared similar. Figure BI shows the record from the middle of sample 19.5 where ferrite (αFe) and cementite (Fe3C) were easily identified, leaving one peak at 35.5 deg that can be associated without much doubt to Fe8Si2C in agreement with the record 00-026-0798 of the Inorganic Crystal Structure Database (ICSD). The height of this line indicates that the SC fraction was low, consistent with the small amount of this phase reported by Kante and Leineweber[2] for alloys with 3.0 and 4.2 wt pct Si.

Experimental XRD pattern in the middle of sample 19.5 in which the main peaks are associated with ferrite (αFe). Only those peaks of cementite (Fe3C) that are not superimposed to αFe peaks have been indicated with small arrows. One peak can be associated with Fe8Si2C that is indicated with the double arrow

The existence of this silico-carbide was verified by metallographic observations on sample 19.5 under the scanning electron microscope (SEM). Figure BII at low magnification shows interconnected graphite string cells in dark contrast in a variable gray contrast matrix. Close observation also reveals small white spots 20 µm in size that are undissolved Te particles. Figure BIII shows an enlarged view of the matrix where the plate-like precipitates in light gray contrast are Fe3C cementite and those in darker gray contrast are SC silico-carbide. This was verified by qualitative energy-dispersive spectrometry (EDS) and is consistent with observations reported by Kante and Leineweber. The remainder of the matrix consists of fine three-phase eutectic zones that were too fine to be properly resolved with the SEM used, while the field electron gun SEM employed by Kante and Leineweber did.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de la Torre, U., Sertucha, J., Regordosa, A. et al. Effect of Silicon on the Metastable Eutectic Temperature of Fe–C–Si Alloys. Metall Mater Trans B 54, 650–660 (2023). https://doi.org/10.1007/s11663-022-02715-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02715-y