Abstract

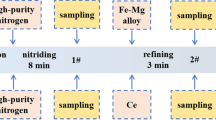

The controls of cleanliness and inclusion characteristics are important issues for the manufacturing of bearing steels. In this work, the method of Mg pretreatment and Ce addition was firstly proposed, and its effect on cleanliness and inclusion evolution in high-nitrogen stainless bearing steels was systematically investigated by microstructure observation and thermodynamic calculation. The results showed that Mg pretreatment and Ce addition decreased O and S contents to 0.0004 and 0.0012 wt pct, respectively. The main inclusions before Mg pretreatment were large-size Al2O3 and elongated MnS. With the increase in Mg content to 0.0079 wt pct, the inclusion evolution processes were Al2O3 → MgO·Al2O3 → MgO, and MnS → MgS. After adding Ce to about 0.015 wt pct, the inclusion evolution processes were Al2O3 → CeAlO3 → Ce–O–S, MgO·Al2O3 → MgO, and MnS → Ce–O–S. Specially, Mg3N2 inclusion formed when Mg content was higher than 0.0040 wt pct, which would induce formation of deleterious AlN. Furthermore, large-size Ce–O–S attached by low-density MgO inclusion tended to float upward because of the decreasing density, thus reducing size and number density of inclusions. However, as Mg content increased to 0.0079 wt pct with same Ce addition, the size and number density of Mg-containing inclusions (MgO, MgS, and Mg3N2) increased. Finally, the optimum Mg content of Mg pretreatment with 0.015 wt pct Ce addition was 0.0026~0.0040 wt pct.

Similar content being viewed by others

References

D.W. Kim: J. Nucl. Mater., 2012, vol. 420, pp. 473–8.

Y. Han, H. Li, H. Feng, K. Li, Y. Tian, and Z. Jiang: J. Mater. Sci. Technol., 2021, vol. 65, pp. 210–5.

W. Horvath, W. Prantl, H. Stroißnigg, and E.A. Werner: Mater. Sci. Eng. A., 1998, vol. 256, pp. 227–36.

D. Molnár, S. Lu, S. Hertzman, G. Engberg, and L. Vitos: Mater. Charact., 2020, vol. 170, p. 110726.

N.B. Dhokey, A. Upadhye, N. Shah, and K.T. Tharian: Mater. Today: Proc., 2021, vol. 43, pp. 3023–9.

L. Becker, A. Röttger, J. Boes, S. Weber, and W. Theisen: Addit. Manuf., 2021, vol. 46, p. 102185.

Y. Han, H. Li, H. Feng, Y. Tian, Z. Jiang, and T. He: Mater. Sci. Eng. A, 2021, vol. 814, p. 141235.

J. Gu, H. Liu, J. Li, Y. Jiang, and R. Chang: J. Iron Steel Res. Int., 2019, vol. 26, pp. 483–9.

H. Feng, H. Li, P. Lu, C. Yang, Z. Jiang, and X. Wu: Acta Metall. Sin., 2019, vol. 55, pp. 1457–68.

Y. Qin, J. Li, and M. Herbig: Mater. Charact., 2020, vol. 159, p. 110049.

H. Feng, Z.H. Jiang, H.B. Li, P.C. Lu, S.C. Zhang, H.C. Zhu, B.B. Zhang, T. Zhang, D.K. Xu, and Z.G. Chen: Corros. Sci., 2018, vol. 144, pp. 288–300.

H. Feng, H.B. Li, Z.H. Jiang, T. Zhang, N. Dong, S.C. Zhang, P.D. Han, S. Zhao, and Z.G. Chen: Corros. Sci., 2019, vol. 158, p. 108081.

W. Trojahn, E. Streit, H.A. Chin, and D. Ehlert: Materialwiss. Werkstofftech., 1999, vol. 30, pp. 605–11.

Z.Y. He, H.B. Li, Z.W. Ni, H.C. Zhu, Z.H. Jiang, H. Feng, and D.S. Mao: Steel Res. Int., 2021, vol. 92, p. 2100197.

Z.X. Cao, Z.Y. Shi, B. Liang, X.D. Zhang, W.Q. Cao, and Y.Q. Weng: Int. J. Fatigue., 2020, vol. 140, p. 105854.

C.Y. Yang, P. Liu, Y.K. Luan, D.Z. Li, and Y.Y. Li: Int. J. Fatigue., 2019, vol. 128, p. 105193.

P.C. Lu, H.B. Li, H. Feng, Z.H. Jiang, H.C. Zhu, Z.Z. Liu, and T. He: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 2210–23.

H. Feng, H.B. Li, Z.Z. Liu, Z.H. Jiang, P.C. Lu, and T. He: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 3777–87.

X. Li, Z. Jiang, X. Geng, M. Chen, and L. Peng: ISIJ Int., 2019, vol. 59, pp. 1552–61.

X. Wang, G. Li, Y. Liu, F. Wang, and Q. Wang: ISIJ Int., 2021, vol. 61, pp. 1850–9.

Q. Ren and L. Zhang: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 589–600.

Z. Jiang, G. Xu, Y. Li, H. Li, J. Lv, and Q. Wang: ISIJ Int., 2019, vol. 59, pp. 1234–41.

F. Chai, C. Yang, H. Su, Y. Zhang, and Z. Xu: J. Iron Steel Res. Int., 2009, vol. 16, pp. 69–74.

Z. Yu and C. Liu: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 772–81.

Y. Huang, G. Cheng, S. Li, and W. Dai: Steel Res. Int., 2018, vol. 89, p. 1800371.

X. Li, Z. Jiang, X. Geng, M. Chen, and S. Cui: Steel Res. Int., 2019, vol. 90, p. 1900103.

R.M. Geng, J. Li, and C.B. Shi: ISIJ Int., 2021, vol. 61, pp. 1506–13.

C. Liu, M. Yagi, X. Gao, S. Kim, F. Huang, S. Ueda, and S. Kitamura: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 113–22.

H. Liu, Y. Xie, Q. Yang, Q. Zhou, and J. Ma: Proceedings of 11th International Symposium on High-Temperature Metallurgical Processing, San Diego, USA, 2020, pp. 595–604

X. Wu, S. Wu, C. Yan, X. Ma, Z. Liu, L. Zhu, and Q. Zhang: Metall. Mater. Trans. B., 2021, vol. 52B, pp. 1012–22.

Q. Ren, L. Zhang, Y. Liu, L. Cui, and W. Yang: J. Mater. Res. Technol., 2020, vol. 9, pp. 8197–206.

C.Y. Yang, Y.K. Luan, D.Z. Li, and Y.Y. Li: J. Mater. Sci. Technol., 2019, vol. 35, pp. 1298–308.

Z.X. Cao, Z.Y. Shi, F. Yu, G.L. Wu, W.Q. Cao, and Y.Q. Weng: Int. J. Fatigue., 2019, vol. 126, pp. 1–5.

W.C. Jiao, H.B. Li, H. Feng, Z.H. Jiang, L.F. Xia, S.C. Zhang, H.C. Zhu, and W. Wu: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 2240–51.

A. Stiénon, A. Fazekas, J.Y. Buffière, A. Vincent, P. Daguier, and F. Merchi: Mater. Sci. Eng. A., 2009, vol. 513–514, pp. 376–83.

P. Wang, B. Wang, Y. Liu, P. Zhang, Y.K. Luan, D.Z. Li, and Z.F. Zhang: Scripta Mater., 2022, vol. 206, p. 114232.

G. Zhu, Y. Wu, M. Zhu, and F. Xuan: Int. J. Fatigue., 2021, vol. 153, p. 106501.

Z. Teng, H. Wu, Z. Huang, and P. Starke: Int. J. Fatigue., 2021, vol. 149, p. 106262.

H.S. Kim, C. Chang, and H. Lee: Scripta Mater., 2005, vol. 53, pp. 1253–8.

Q. Ma, C. Wu, G. Cheng, and F. Li: Mater. Today: Proc., 2015, vol. 2, pp. S300–5.

L. Yang and G.G. Cheng: Int. J. Miner. Metall. Mater., 2017, vol. 24, pp. 869–75.

S. He, G. Chen, Y. Guo, B. Shen, and Q. Wang: Metall. Mater. Trans. B., 2015, vol. 46B, pp. 585–94.

K. Hashimoto, T. Fujimatsu, N. Tsunekage, K. Hiraoka, K. Kida, and E.C. Santos: Mater. Des., 2011, vol. 32, pp. 1605–11.

K. Wang, T. Yu, Y. Song, H. Li, M. Liu, R. Luo, J. Zhang, F. Fang, and X. Lin: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 1213–24.

J. Lu, G. Cheng, J. Che, L. Wang, and G. Xiong: Met. Mater. Int., 2019, vol. 25, pp. 473–86.

S. Yang, Q. Wang, L. Zhang, J. Li, and K. Peaslee: Metall. Mater. Trans. B., 2012, vol. 43B, pp. 731–50.

J.H. Park and D.S. Kim: Metall. Mater. Trans. B., 2005, vol. 36B, pp. 495–502.

W. Ma, Y. Bao, M. Wang, and L. Zhao: ISIJ Int., 2014, vol. 54, pp. 536–42.

X. Zheng, Q. Wang, M. Zhou, and C. Li: Sci. China Technol. Sci., 2002, vol. 45, pp. 249–54.

H.Z. Ye, X.Y. Liu, and B. Luan: Mater. Lett., 2004, vol. 58, pp. 2361–4.

Acknowledgments

This research was sponsored by the National Natural Science Foundation of China [Grant Nos. U1960203/52004060/U1908223], Fundamental Research Funds for the Central Universities [Grant No. N2125017], China National Postdoctoral Program for Innovative Talents [Grant No. BX20200076], China Postdoctoral Science Foundation [Grant No. 2020M670775], Talent Project of Revitalizing Liaoning [Grant No. XLYC1902046], and Northeastern University Postdoctoral Funds [Grant No. 20200101]. Special thanks are due to the instrumental analysis from Analytical and Testing Centre, Northeastern University.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 9, 2021; accepted November 24, 2021.

Rights and permissions

About this article

Cite this article

Feng, H., Lu, PC., Li, HB. et al. Effect of Mg Pretreatment and Ce Addition on Cleanliness and Inclusion Evolution in High-Nitrogen Stainless Bearing Steels. Metall Mater Trans B 53, 864–876 (2022). https://doi.org/10.1007/s11663-021-02409-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02409-x