Abstract

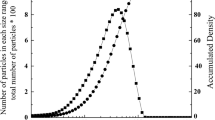

A novel experimental setup for simultaneous weight, surface temperature, and center temperature tracking of a single iron ore pellet under reducing conditions has been utilized. Studies conducted in the setup indicate that the reduction of iron ore pellets in a pure hydrogen atmosphere is controlled by several transport steps inside the pellet. It is further shown that for a period of time during reduction, the reduction rate is limited by the heat transfer inside the sample. Any attempt to make accurate and robust models of the hydrogen based iron ore reduction process must therefore consider heat transfer in the pellet. The reduction is observed to take place in a reduction zone extending along the pellet radius, consisting of a mix of different phases. The amount of the different phases varies with radial position and time, as does the observed temperature gradient between the surface and the center of the pellet. Representative literature data on actual transfer coefficients of this system is therefore not available. Apparent thermal conductivities for the different experimental temperatures are evaluated based on the experimental data and found to be significantly lower than the corresponding value for dense iron.

Similar content being viewed by others

References

IPCC, Global warming of 1.5°C (2018), www.ipcc.ch. Accessed 9 June 2021.

World Steel Association, Steel's contribution to a low carbon future and climate resilient societies (2018), www.worldsteel.com. Accessed 9 June 2021.

HYL, ENERGIRON, DRI technology by Tenova and Danieli (2014), www.tenova.com. Accessed 9 June 2021.

MIDREX, MIDREX global solutions brochure (2018), www.midrex.com. Accessed 9 June 2021.

D. Spreitzer and J. Shenk: Steel Res. Int., 2019, vol. 90, p. 1900108.

M. Wiberg: Jenkontorets annaler 124, 1940, vol. 5, pp. 179–212.

O. Edström: J. Iron Steel Inst., 1953, vol. 175, pp. 289–304.

E.T. Turkdogan and J.V. Vinters: Metall Mater. Trans. B., 1971, vol. 2B, pp. 3175–88.

R. Takahashi, J.-I. Yagi and Y. Omori: Sci. Rep. Res. Inst. Tohoku Univ. Ser. A, 1971, vol. 23, pp. 9–30

Y. Man and J.-X. Feng: Powder Technol., 2016, vol. 301, pp. 1213–7.

D. Gao, M. Hu, C. Pu, B. Xiao, Z. Hu, S. Lui, W. Xun, and X. Zhu: Int. J. Hydrogen Energy., 2015, vol. 40(14), pp. 4733–40.

M. Kazemi, M. Saffari Pour, and D. Sichen: Metall. Mater. Trans. B., 2017, vol. 48B, pp. 1114–22.

A. Ranzani da Costa, D. Wagner and F. Patisson: J. Cleaner Prod., 2013, vol. 46, no. Key Elements (Stages and Tools) for a Sustainable World, pp. 27–35.

M. Kazemi, B. Glaser, and D. Sichen: Steel Res. Int., 2014, vol. 85(4), pp. 718–28.

M. Kazemi: KTH Royal Institute of Technology, Stockholm, 2012, Ph.D. Thesis.

D. Wagner, O. Devisme, F. Patisson and D. Ablitzer: Adv. Process. Met. Mater. Sohn Int. Symp., 2006, vol. 2, pp. 111–20.

E. Kawasaki, J. Sanscrainte, and T.J. Walsh: AIChE J., 1962, vol. 8, pp. 48–52.

Z. Chen, J. Dang, X. Hu, and H. Yan: Metals., 2018, vol. 8(10), p. 751.

A. Pineau, N. Kanari, and I. Gaballah: Thermochim. Acta., 2006, vol. 447(1), pp. 89–100.

F. Patisson and O. Mirgaux: Metals., 2020, vol. 10(27), pp. 922–36.

E.T. Turkdogan and J.V. Vinters: Can. Metall. Q., 1973, vol. 12(1), pp. 9–21.

P.K. Strangwa, S. Toppis, and H.U. Ross: Can. Metall. Q., 1966, vol. 5(3), pp. 211–9.

Y. Hara, M. Tsuchiya, and S.-I. Kondo: Trans. Iron Steel Inst. Jpn., 1974, vol. 60(1), pp. 1261–70.

K. Sato, Y. Nishikawa, and I. Tamura: Trans. Iron Steel Inst. Jpn., 1983, vol. 69(9), pp. 1137–44.

Z. Ariyan, V. Sadegh, and B. Mojtaba: J. Iron Steel Res. Int., 2016, vol. 23(11), pp. 1142–50.

T. Usui, M. Ohmi, and E. Yamamura: ISIJ Int., 1990, vol. 30(5), pp. 347–55.

E.T. Turkdogan: Physical Chemistry of High Temperature Technology, Academic Press, New York, 1980.

Acknowledgments

This work has been conducted as part of the HYBRIT research project RP1. We gratefully acknowledge financial support from the Swedish Energy Agency. HYBRIT (Hydrogen Breakthrough Ironmaking Technology) is a joint initiative of the three companies SSAB, LKAB and Vattenfall with the aim of developing the world’s first fossil-free ore-based steelmaking route.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 11, 2021; accepted November 24, 2021.

Rights and permissions

About this article

Cite this article

Hessling, O., Fogelström, J.B., Kojola, N. et al. The Effect of the Endothermic Reaction Nature on the Iron Ore Pellet Reduction Using Hydrogen. Metall Mater Trans B 53, 1258–1268 (2022). https://doi.org/10.1007/s11663-021-02405-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02405-1