Abstract

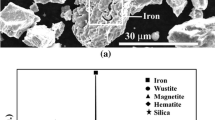

Novel ironmaking technologies that directly use the raw materials of iron ore fines without preprocessing have greater benefits in environmental protection and energy conservation. In this work, the gas–liquid reduction behavior and kinetic mechanism of hematite ore fines in the flash reduction processes are investigated using a high-temperature drop tube furnace. Morphological observations show the hematite ores to be completely molten at 1700 K and above. The metallic iron is enwrapped in the liquid wüstite and the aggregation state of metallic iron inside the wüstite is highly dependent on the reaction temperature. Many small irregularly shaped iron particles are found to be scattered in the liquid wüstite at 1650 K to 1700 K, while only one big spherical iron particle is observed at 1700 K to 1800 K. The gas–liquid reduction reaction always occurs at the surface of the liquid wüstite particle, and the kinetic analysis reveals that the interfacial chemical reaction at the liquid wüstite surface is the rate-controlling step during the reduction process. The chemical kinetics limiting rate equation of gas–liquid reduction is determined. The activation energies of the gas–liquid reaction calculated by the model-fitting and the model-free approaches are 148 and 143 kJ/mol, respectively.

Similar content being viewed by others

References

X. Liu, L. Chen, X. Qin and F. Sun: Energy, 2015, vol. 93, pp. 10-19.

P. Michaelis, T. Jackson and R. Clift: Energy, 1998, vol.23, pp. 213-20.

W. Sun, J. Cai, H. Mao and D. Guan: J Iron Steel Res Int., 2011, vol. 18, pp. 31-6.

Y. You, Q. Hou and Z. Luo: Steel Res. Int, 2016, vol. 87, pp. 1543-51.

D. Stephens, M. Tabib and M. Schwarz: Prog Comput Fluid Dyn, 2012, vol. 12, pp. 196-06.

W. Zhang, J. Zhang and Z. Xue: Energy, 2017, vol. 121, pp. 135-46.

A. Habermann, F. Winter, H. Hofbauer, J. Zirngast and J. L. Schenk: ISIJ Int., 2000, vol. 40, pp. 935-42.

K. Meijer, C. Zeilstra, C. Teerhuis, M. Ouwehand and J. V. D. Stel: Trans. Indian Inst. Met., 2013, vol. 66, pp. 475-81.

M. A. Quader, S. Ahmed, S. Z. Dawal and Y. Nukman: Renew. Sustain. Energy Rev., 2016, vol. 55, pp. 537-49.

A. Orth, N. Anastasijevic and H. Eichberger: Miner Eng., 2007, vol. 20, pp. 854-61.

H. K. Pinegar, M. S. Moats and H. Y. Sohn: Steel Res. Int., 2011, vol. 82, pp. 951-63.

H. Y. Sohn: Steel Times Int., 2007, vol. 31, pp. 68-72.

H. Y. Sohn, S. Roy and D. Q. Fan: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2037-46.

R. Sarka and H. Y. Sohn: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2063-76.

Q. Wang, G. Li, W. Zhang and Y. Yang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2006-16.

B. Weiss, J. Sturn, S. Volglsam, H. Strobl, H. Mail, F. Winter and J. Schenk: Ironmaking Steelmaking., 2011, vol. 38, pp. 65-73.

J. Pang, P. Guo and P. Zhao: Iron Steel Res. Int., 2015, vol. 22, pp. 391-95.

H. Wang and H. Y. Sohn: ISIJ Int., 2015, vol. 55, pp. 706-08.

H. Wang and H. Y. Sohn: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1133-45.

F. Chen, Y. Mohassab, T. Jiang and H. Y. Sohn: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1133-45.

F. Chen, Y. Mohassab, S. Zhang and H. Y. Sohn: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1716-28.

F. Tsukihashi, K. Kato, K. Otsuka and T. Soma: Trans. Iron Steel Inst. Jpn. 1982, vol. 22, pp. 688-95.

S. Hayashi and Y. Iguchi, ISIJ Int. 1994, vol. 34, pp. 555-61.

Y. Qu, Y. Yang, Z. Zou, C. Zeilstra, K. Meijer and R. Boom: Ironmaking. Steelmaking, 2015, vol. 42, pp. 763-73.

A. A. Barde, J. K. Klausner and R. Mei: Int. J. Hydrogen Energy, 2016, vol. 41, pp. 10103-19.

M. H. Jeong, D. H. Lee and W. Bae: Int. J. Hydrogen Energy, 2015, vol. 40, pp. 2613-20.

D. R. Gaskell: An Introduction to Transport Phenomena in Materials Engineering, Macmillan Publishing Company, New York, USA 2013.

Y. Qu, Y. Yang, Z. Zou, C. Zeilstra, K. Meijer and R. Boom: ISIJ Int., 2015, vol. 55, pp. 952-60.

K. Nozawa, M. Shimizu and S. Inaba: Trans. Iron Steel Inst. Jpn. 1992, vol. 79, pp. 443-48.

Y. Guo, L. Jia, B. Kong, S. Zhang, F. Zhang and H. Zhang: Appl. Surf. Sci, 2017, vol. 409, pp. 367-74.

P. Hu, G. Liu, B. Hu, W. Ma, Y. Zhang and J. Liu: J. Univ. Sci. Technol. Beijing, 2013, vol. 35, pp. 1174-80.

B. Verdes, I. Chira, M. Virgolici and V. Moise: U. P. B. Sci. Bull, 2012, vol. 74, pp. 257-68.

L. Xing, Z. Zou, Y. Qu, L. Shao and J. Zou: Steel Res. Int. 2019, https://doi.org/10.1002/srin.201800311.

M.F. Rau, D. Rieck, J.W. Evans: Metall. Mater. Trans. B, 1987, vol. 18B, pp. 257–78.

A. Khawam and D. R. Flanagan: J. Pharm. Sci., 2006, vol. 95, pp. 472-98.

A. Khawam and D. R. Flanagan: J. Phys. Chem. B, 2006, vol. 110, pp. 17315-28.

Acknowledgments

The authors are grateful for the financial support from the National Natural Science Foundation of China (Grants Nos. 51504056, 51604068 and 51574064), and the Fundamental Research Funds for the Central Universities (Grant No. N182504012).

Conflict of interest

All authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 17, 2019.

Rights and permissions

About this article

Cite this article

Xing, L., Qu, Y., Wang, C. et al. Gas–Liquid Reduction Behavior of Hematite Ore Fines in a Flash Reduction Process. Metall Mater Trans B 51, 1233–1242 (2020). https://doi.org/10.1007/s11663-020-01811-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01811-1