Abstract

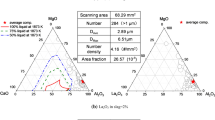

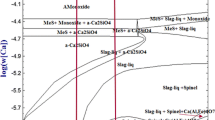

The slag composition plays a critical role in the formation of inclusions and the cleanliness of steel. In this study, the effects of FeO content and the C/A (CaO/Al2O3) ratio in the slag on the formation of inclusions were investigated based on a 10-minute slag–steel reaction in a MgO crucible. The FeO content in the top slag was shown to have a significant effect on the formation of MgO·Al2O3 spinel inclusions, and critical content exists; when the initial FeO content in the slag was less than 2 pct, MgO·Al2O3 spinel inclusions formed, and the T.O (total oxygen) was 20 ppm; when the initial FeO content in the slag was more than 4 pct, only Al2O3 inclusions were observed and the T.O was 50 ppm. It was clarified that the main source of Mg for the MgO·Al2O3 spinel inclusion formation was the top slag rather than the MgO crucible. In addition, the cleanliness of the steel increased as the initial FeO content in the top slag decreased. As regards the effects of the C/A ratio, the MgO amount in the observed inclusions gradually increased, whereas the T.O content decreased gradually with the increasing C/A ratio. Slag with a composition close to the CaO-saturated region had the best effect on the inclusion absorption.

Similar content being viewed by others

References

H. Tanaka, R. Nishihara, I. Kitagawa, R. Tsujino: ISIJ Int., 1993, vol. 33, pp. 1238-1243.

K. Reitmann, A. Kursfeld, U. Muschner, and H. Holzgruber: 2nd European Continuous Casting Conference, Düsseldorf, 20–22 June 1994, Proceedings, vol. 1, p. 141.

K.K. Lee, J.M. Park, J.Y. Chung, S.H. Choi, and S.B. Ahn: La Revue de Métallurgie-CIT, 1996, pp. 503–509.

M. Kitamura, T. Soejima, S. Koyama, Y. Matsuda, J. Abu, and Y. Nimiya: ISIJ Int., 1994, vol. 24, pp. 966-972.

Y. Qin, X. Wang, L. Li and F. Huang: Steel Res.Int., 2015, vol. 86, pp. 1037-1045.

L. Zhang, B. Thomas: ISIJ Int., 2003, vol. 43, pp. 271-291.

C. Liu, F. Huang, J. Suo, and X. Wang: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 989–998.

C. Liu, F. Huang, and X. Wang: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 999–1009.

C. Liu, X. Gao, S. Ueda, and S. Y. Kitamura: ISIJ Int., 2018, vol. 58, pp. 488-495.

K.J. Graham and G.A. Irons: AISTech 2009 Proceedings, pp. 1003–11.

J. Mendez, A. Gomez, C. Capurro, R. Donayo, and C. Cicutti: Clean Steel 8 Conference 2012, Budapest.

C. Cicutti, C. Capurro, and G. Cerrutti: Clean Steel 9 Conference 2015, Budapest.

G. Chen, Y. Guo,and S. He: Metall. Res. Technol., 2016, vol. 113 (204), pp. 1-10.

J-Y. Choi and H-G. Lee: ISIJ Int., 2003, vol. 43, pp. 1348-1355.

J-Y. Choi, H-G. Lee, and J-S. Kim: ISIJ Int., 2002, vol. 42, pp. 852-860.

M. Valdez, G. S. Shannon, and S. Sridhar: ISIJ Int., 2006, vol. 46, pp. 450-457.

B. H. Reis, W. V. Bielefeldt, and A. C. F. Vilela: J. Mater. Res., 2014, vol. 3, pp. 179-185.

B. J. Monaghan and L. Chen: Ironmak. Steelmak., 2006, vol. 33(4), pp. 323-330.

A. Harada, G. Miyano, N. Maruoka, H. Shibata, and S-Y. Kitamura: ISIJ Int., 2014, vol. 54, pp. 2230-2238.

H. Ohta and H. Suito: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 1131-1139.

H. Itoh, M. Hino, and S. Ban-ya: Tet. Hag., 1997, vol. 83, pp. 623-628.

Q. Han, D. Zhou, and C. Xiang: Steel Res.Int., 1997, vol. 68, pp. 9-14.

J. Gran and S. Du: Metall. Mater. Trans. B, 2011, vol. 32B, pp. 921-924.

M. Hino and K. Ito: Thermodynamic Data for Steelmaking: The 19th Committee in Steelmaking, The Japan Society for Promotion of Science, Tokyo, 2010.

Acknowledgments

The authors are grateful for financial support from the National Key R&D Program of China (2017YFB0304000 & 2017YFB0304001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 1, 2018.

Rights and permissions

About this article

Cite this article

Ji, Y., Liu, C., Lu, Y. et al. Effects of FeO and CaO/Al2O3 Ratio in Slag on the Cleanliness of Al-Killed Steel. Metall Mater Trans B 49, 3127–3136 (2018). https://doi.org/10.1007/s11663-018-1397-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1397-2