Abstract

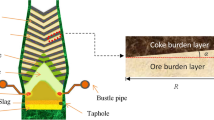

In order to reduce ironmaking-related CO2 emissions, hydrogen-enriched blast furnace (BF) operation is currently under development. In hydrogen-enriched BF operation, coke layer thickness can be decreased to reduce CO2 emissions. However, BFs operating with thin coke layers may experience instability or discontinuous phenomena such as particle slip and gas channeling problems, so it is important to optimize the particle diameter and coke layer thickness for optimal BF operation. In this study, the effects of particle diameter and coke layer thickness on the solid flow and stress distribution in a BF were analyzed using a three-dimensional discrete element method. Furthermore, the effects of particle diameter and coke layer thickness on the burden layer stabilities, particle velocities, and particle stress distributions have been investigated. The results show that decreasing the coke layer thickness caused instability owing to the mixing of the coke and ore layers in the BF-cohesive zone and slight increases in both the average particle velocities and the average normal particle stress magnitudes. In addition, the average particle velocities and average normal particle stresses were higher for the smaller particles than for the larger ones during the simulations.

Similar content being viewed by others

References

A. Adema, Y. Yang, and R. Boom: ISIJ Int., 2010, vol. 50, pp. 954–961.

J. De Castro, H. Nogami, and J. Yagi: ISIJ Int., 2001, vol. 41, pp. 18–24.

M. Chu, H. Nogami, and J. Yagi: ISIJ Int., 2004, vol. 44, pp. 801–808.

H. Nogami, P. Austin, J. Yagi, and K. Yamaguchi: ISIJ Int., 2004, vol. 44, pp. 500–509.

H. Nogami, H. Yamaoka, and K. Takatani: ISIJ Int., 2004, vol. 44, pp. 2150–2158.

J. Castro, H. Nogami, and J. Yagi: ISIJ Int., 2000, vol. 40, pp. 637–646.

S. Natsui, T. Kikuchi, and R. Suzuki: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 2395–2413.

S. Yuu, T. Umekage, S. Matsuzaki, M. Kadowaki, and K. Kunitomo: ISIJ Int., 2010, vol. 50, pp. 962–971.

X. Dong, A. Yu, S. Chew, and P. Zulli: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 330–349.

J. Yagi: ISIJ Int., 1993, vol. 33, pp. 619–639.

X. Dong, A. Yu, J. Yagi, and P. Zulli: ISIJ Int., 2007, vol. 47, pp. 1553–1570.

X. Dong, A. B. Yu, J. Burgess, D. Pinson, S. Chew, and P. Zulli: Ind. Eng. Chem. Res., 2009, vol. 48, pp. 214–226.

S. Zhang, A. Yu, P. Zulli, B. Wright, and P. Austin: Appl. Math. Model., 2002, vol. 26, pp. 141–154.

S. Story and R. Fruehan: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 43–54.

M. Shin, S. Min, J. Lee, J. Park, and D. Min: Met. Mater. Int., 2012, vol. 18, pp. 1041–1047.

M. Shin, J. Oh, and J. Lee: ISIJ Int., 2015, vol. 55, pp. 2056–2063.

D. Jang, Y. Kim, M. Shin, and J. Lee: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 1308–1314.

H. Bertling: ISIJ Int., 1999, vol. 39, pp. 617–624.

Y. Kashihara, Y. Iwai, N. Ishiwata, N. Oyama, H. Matsuno, H. Horikoshi, K. Yamamoto, and M. Kuwabara: ISIJ Int., 2017, vol. 57, pp. 665–672.

Y. Kashihara, Y. Iwai, T. Sato, N. Ishiwata, and M. Sato: ISIJ Int., 2015, vol. 55, pp. 1237–1244.

K. Ichikawa, Y. Kashihara, N. Oyama, T. Hirosawa, J. Ishii, M. Sato, and H. Matsuno: ISIJ Int., 2017, vol. 57, pp. 254–261.

J. Chung and N. Hur: ISIJ Int., 1997, vol. 37, pp. 119–125.

K. Takahashi, T. Nouchi, M. Sato, and T. Ariyama: ISIJ Int., 2015, vol. 55, pp. 1866–1875.

M. Sato, K. Takahashi, T. Nouchi, and T. Ariyama: ISIJ Int., 2015, vol. 55, pp. 2105–2114.

H. Nogami, Y. Kashiwaya, and D. Yamada: ISIJ Int., 2012, vol. 52, pp. 1523–1527.

J. Li, P. Wang, L. Zhou, and M. Cheng: ISIJ Int., 2007, vol. 47, pp. 1097–1101.

M. Geerdes, H. Toxopeus, and C. van der Vliet: Modern Blast Furnace Ironmaking: An Introduction, Second Ed., IOS Press B.V., Amsterdam, 2009, pp. 67–92.

Z. Fan, S. Igarashi, S. Natsui, S. Ueda, T. Yang, R. Inoue, and T. Ariyama: ISIJ Int., 2010, vol. 50, pp. 1406–1412.

K. Yang, S. Choi, J. Chung, and J. Yagi: ISIJ Int., 2010, vol. 50, pp. 972–980.

D. Fu, Y. Chen, Y. Zhao, J. D’Alessio, K. Ferron, and C. Zhou: Appl. Therm. Eng., 2014, vol. 66, pp. 298–308.

P. Cundall and O. Strack: Geotechnique, 1979, vol. 29, pp. 47–65.

J. Park, H. Jung, M. Jo, H. Oh, and J. Han: Met. Mater. Int., 2011, vol. 17, pp. 485–496.

Y. Tsuji, T. Kawaguchi, and T. Tanaka: Powder Technol., 1993, vol. 77, pp. 79–87.

Q. Hou, E. Dianyu, S. Kuang, Z. Li, and A. B. Yu: Powder Technol., 2017, vol. 314, pp. 557–566.

B. Xu, A. B. Yu, S. J. Chew, and P. Zulli: Powder Technol., 2000, vol. 109, pp. 13–26.

B. H. Xu and A. B. Yu: Chem. Eng. Sci., 1997, vol. 52, pp. 2785–2809.

S. Matsuhashi, H. Kurosawa, S. Natsui, T. Kon, S. Ueda, R. Inoue, and T. Ariyama: ISIJ Int., 2012, vol. 52, pp. 1990–1999.

H. Zhu, Z. Zhou, A. B. Yu, and P. Zulli: Granul. Matter, 2009, vol. 11, pp. 269–280.

S. Natsui, S. Ueda, H. Nogami, J. Kano, R. Inoue, and T. Ariyama: ISIJ Int., 2011, vol. 51, pp. 1410–1417.

T. Ariyama, S. Natsui, T. Kon, S. Ueda, S. Kikuchi, and H. Nogami: ISIJ Int., 2014, vol. 100, pp. 198–210.

S. Natsui, S. Ueda, H. Nogami, J. Kano, R. Inoue, and T. Ariyama: ISIJ Int., 2011, vol. 51, pp. 51–58.

S. Ueda, T. Kon, H. Kurosawa, S. Natsui, T. Ariyama, and H. Nogami: ISIJ Int., 2015, vol. 55, pp. 1232–1236.

S. Natsui, H. Nogami, S. Ueda, J. Kano, R. Inoue, and T. Ariyama: ISIJ Int., 2011, vol. 51, pp. 41–50.

Z. Miao, Z. Zhou, A. B. Yu, and Y. Shen: Powder Technol., 2017, vol. 314, pp. 542–549.

H. Kurosawa, S. Matsuhashi, S. Natsui, T. Kon, S. Ueda, R. Inoue, and T. Ariyama: ISIJ Int., 2012, vol. 52, pp. 1010–1017.

Z. Y. Zhou, H. P. Zhu, A. B. Yu, B. Wright, and P. Zulli: Comput. Chem. Eng., 2008, vol. 32, pp. 1760–1772.

Z. Fan, S. Natsui, S. Ueda, T. Yang, J. Kano, R. Inoue, and T. Ariyama: ISIJ Int., 2010, vol. 50, pp. 946–953.

J. Zhang, Y. Chen, Z. Fan, Z. Hu, T. Yang, and T. Ariyama: J. Iron Steel Res. Int., 2011, vol. 18, pp. 1–6.

S. Natsui, S. Ueda, Z. Fan, N. Andersson, J. Kano, R. Inoue, and T. Ariyama: ISIJ Int., 2010, vol. 50, pp. 207–214.

S. Natsui, S. Ueda, M. Oikawa, Z. Fan, J. Kano, R. Inoue, and T. Ariyama: ISIJ Int., 2009, vol. 49, pp. 1308–1315.

M. Keyser, M. Conradie, M. Coertzen, and J. Van Dyk: Fuel, 2006, vol. 85, pp. 1439–1445.

T. Nouchi, T. Sato, M. Sato, K. Takeda, and T. Ariyama: ISIJ Int., 2005, vol. 45, pp. 1426–1431.

Y. Yu, A. Westerlund, T. Paananen, and H. Saxen: ISIJ Int., 2011, vol. 51, pp. 1050–1056.

Y. Yu and H. Saxen: ISIJ Int., 2012, vol. 52, pp. 788–796.

Z. Zhou, H. Zhu, A. Yu, B. Wright, D. Pinson, and P. Zulli: ISIJ Int., 2005, vol. 45, pp. 1828–1837.

S. Kikuchi, T. Kon, S. Ueda, S. Natsui, R. Inoue, and T. Ariyama: ISIJ Int., 2015, vol. 55, pp. 1313–1320.

F. Zhengyun, S. Natsui, S. Ueda, J. Kano, R. Inoue, and T. Ariyama: Tetsu-to-Hagane, 2010, vol. 96, pp. 1–10.

Y. Omori: Blast Furnace Phenomena and Modelling, Elsevier Applied Science Publishers, London, 1987, pp. 3–63.

Acknowledgments

This study was supported by the Industrial Strategic Technology Development Program (20172010106300, Development of Hybrid ironmaking processes for lower CO2 emissions) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea). The authors are grateful to Assistant Professor Shungo Natsui at Hokkaido University for his informative discussion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 26, 2018.

Rights and permissions

About this article

Cite this article

Geleta, D.D., Lee, J. Effects of Particle Diameter and Coke Layer Thickness on Solid Flow and Stress Distribution in BF by 3D Discrete Element Method. Metall Mater Trans B 49, 3594–3602 (2018). https://doi.org/10.1007/s11663-018-1368-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1368-7