Abstract

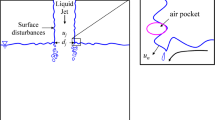

Oxide inclusions form during pouring of metal castings as a result of air entrainment. Recently, a model was developed by the authors to predict the volumetric air entrainment during pouring. It was found that the velocity, diameter, and turbulence intensity of the liquid stream affect the air entrainment rate during pouring. In this study, the developed air entrainment model is validated with water modeling experiments. In the water modeling studies, water was poured using a bottom pour ladle. The effects of nozzle opening, head height, nozzle diameter, and nozzle extension are simulated. The predictions compare favorably with the experimental measurements. Results indicate that low head height and short pouring time have a beneficial effect on reducing the air entrainment during pouring. In addition, a fully open nozzle and the use of a nozzle extension further reduce the amount of entrained air.

Similar content being viewed by others

References

J. Campbell: Complete Casting Handbook, 1st ed., Butterworth-Heinemann, Oxford, UK, 2011.

A.J. Melendez, K.D. Carlson and C. Beckermann: Int. J. Cast Met. Res., 2010, vol. 23, pp. 278–288.

D.R. Askeland, P.K. Trojan and R.A. Flinn: AFS Trans., 1972, vol. 80, pp. 349-58.

J. Campbell: Mater. Sci. Tech., 2006, vol. 22, pp. 127-45.

M. Divandari and J. Campbell: Aluminum Trans., 2000, vol. 2, pp. 233-238.

T.J. Lin and H.G. Donnelly: AIChE, 1966, vol. 12, pp. 563-571.

A.K. Biń: Chem. Eng. Sci., 1993, vol. 48, pp. 3585-3630.

D.A. Ervine, E. McKeough and E.M. Elsawy: ICE Proc., 1980, vol. 69, pp. 425-445.

K.J. Sene: Chem. Eng. Sci., 1988, vol. 43, pp. 2615-2623.

E. Van de Sande and J.M. Smith: Chem. Eng. Sci., 1976, vol. 31, pp. 219-224.

T. Brattberg and H. Chanson: Chem. Eng. Sci., 1998, vol. 24, pp. 4113-4127.

C. Wanstall, J. Griffin and C.E. Bates: Proc. 47th SFSA Technical and Operating Conference, Chicago, IL, 1993, Paper No. 1.1.

C.E. Bates and J. Griffin: Research report no. 106, Steel Founders’ Society of America (SFSA), Crystal Lake, IL, USA, 1994.

S. Kuyucak: AFS Trans., 2006, vol. 114, pp. 811-818.

T. Wang, S. Yao, Q. Tong and L. Sui: J. Manuf. Process, 2017, vol. 27, pp. 108-113.

M. Afsharpour, B. Homayun and S.M.A. Boutorabi: Mater. Sci. Tech., 2014, vol. 30, pp. 152-159.

J. Ma, A.A. Oberai, D.A. Drew, R.T. Lahey and M. Hyman: J. Comput. Multiphase Flow, 2011, vol. 3, pp. 41-56.

S.H. Majidi and C. Beckermann: Int. J. Cast Met. Res., 2017, vol. 30, pp. 301-315.

MAGMAsoft, MAGMA Gmbh, Kackerstrasse 11, 52072 Aachen, Germany.

F. White: Fluid Mechanics, 7th ed., Mcgraw Hill Higher Education, New York, USA, 2010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 2, 2018.

Rights and permissions

About this article

Cite this article

Majidi, S.H., Griffin, J. & Beckermann, C. Simulation of Air Entrainment during Mold Filling: Comparison with Water Modeling Experiments. Metall Mater Trans B 49, 2599–2610 (2018). https://doi.org/10.1007/s11663-018-1334-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1334-4