Abstract

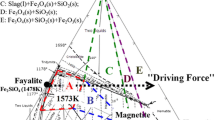

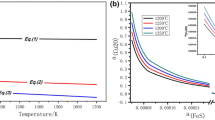

A novel approach for quickly separating a metal copper phase and iron-rich phase from copper slag at low temperature is proposed based on a super-gravity method. The morphology and mineral evolution of the copper slag with increasing temperature were studied using in situ high-temperature confocal laser scanning microscopy and ex situ scanning electron microscopy and X-ray diffraction methods. Fe3O4 particles dispersed among the copper slag were transformed into FeO by adding an appropriate amount of carbon as a reducing agent, forming the slag melt with SiO2 at low temperature and assisting separation of the copper phase from the slag. Consequently, in a super-gravity field, the metallic copper and copper matte were concentrated as the copper phase along the super-gravity direction, whereas the iron-rich slag migrated in the opposite direction and was quickly separated from the copper phase. Increasing the gravity coefficient (G) significantly enhanced the separation efficiency. After super-gravity separation at G = 1000 and 1473 K (1200 °C) for 3 minutes, the mass fraction of Cu in the separated copper phase reached 86.11 wt pct, while that in the separated iron-rich phase was reduced to 0.105 wt pct. The recovery ratio of Cu in the copper phase was as high as up to 97.47 pct.

Similar content being viewed by others

References

P. J. Mackey. Can. Metall. Q. 2013, vol. 18, pp. 221-260.

G. Liu, R. Zhu. MING & METALL. 2008, vol. 17, pp. 59-64.

D. F. Qiu, Y. Q. Wu, B. Fu, C. H. Xu. Energy Saving of Nonferrous Metallurgy. 2005, vol. 4, pp. 6-13.

S. Etsurou, H. P. Sun, M. Katsumi. ISIJ International, 1999, vol. 85, pp. 27-32.

Y. W. Chen. WORLD NONFERROUS METALS, 2001, vol. 9, pp. 53-58.

C. Arslan, F. Arslan. Hydrometallurgy. 2002, vol. 27, pp. 1-7.

R. Sridhar, J. M. Toguri, S. Simeonov. Metall. Mater. Trans. B. 1997, vol. 28, pp. 191-200.

S. W. Ip, J. M. Toguri. Metall. Mater. Trans. B. 1992, vol. 23, pp. 303-311.

H. Y. Cao, L. Zhang, N. X. Fu, F. S. Xia, Z. T. Sui. J. Mater. Metall. 2009, vol. 8, pp. 33-39.

D. X. Liu. Nonferrous Met. 2002, vol. 54, pp.6-10.

P. Coursol, N. C. Valencia, P. Mackey, S. Bell, B. Davis. JOM. 2012, vol. 64, pp. 1305-1313.

R. R. Moskalyk, A. M. Alfantantazi. MINER ENG. 2003, vol.16, pp. 893-919.

M. J. Chen, Energy Saving of Nonferrous Metallurgy. 2013, vol. 2, pp. 46-49.

X. M. Zhu, M. S. Chen, P. Ning, Z. R. Han, Y. X. Ma. MATER REV. 2013, vol. 27, pp. 280-284.

B. Gora, R. K. Jana, Premchand. Resource, Conserv Recycl. 2003, vol. 39, pp. 299-313.

Y. Y. Zhou. Non-Ferrous Mining and Metallurgy. 1988, vol. 5, pp.39-40.

J. Li, M. L. Sun, K. X. Huang. Nonferrous Met. 1990, vol. 5, pp. 20-22.

G. Z. Wu, W. Ute, G. R. Wu. Journal of Northeast University of Technology. 1989, vol. 10, pp. 388-393.

J. Li, M. L. Sun, K. X. Huang. J. CENT. SOUTH INST. MIN. METAL. 2008, Vol.20, pp. 448-455.

C. Ramshaw, R. H. Mallinson. EP, EP0002568, 1984.

M. R. Rahimipour, M. Sobhani. Metall. Mater. Trans. B. 2013, vol. 44, pp. 1120-1123.

T. P. D. Rajan, R. M. Pillai, B. C. Pai. Int. J. Cast Metal Res. 2013, vol. 21, pp. 214-218.

J. T. Gao, Y. W. Zhong, Z. C. Guo, Metall. Mater. Trans. B. 2016, vol. 47, pp. 2459-2467.

Y. Lu, J. T. Gao, F. Q. Wang, Z. C. Guo. Metall. Mater. Trans. B. 2017, vol. 48, pp. 749-753.

J. T. Gao, Y. Li, G. L. Xu, F. Q. Wang, Y. Lu, Z. C. Guo. ISIJ International, 2017, vol. 57, pp. 587-589.

26. J. T. Gao, Y. W. Zhong, Z. C. Guo. ISIJ International, 2016, vol. 56, pp. 1352-1357.

Acknowledgments

This study is supported by the National Natural Science Foundations of China (No. 51774037 and No. 51404025).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 15, 2017.

Rights and permissions

About this article

Cite this article

Lan, X., Gao, J., Huang, Z. et al. Rapid Separation of Copper Phase and Iron-Rich Phase From Copper Slag at Low Temperature in a Super-Gravity Field. Metall Mater Trans B 49, 1165–1173 (2018). https://doi.org/10.1007/s11663-018-1235-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1235-6