Abstract

COREX is one of the commercial smelting reduction processes. It uses the finer size ore and semi-soft coal instead of metallurgical coke to produce hot metal from iron ore. The use of top gas with high calorific value as a by-product export gas makes the process economical and green. The predictive thermochemical model of the COREX process presented here enables rapid computation of process parameters such as (1) required amount of ore, coal, and flux; (2) amount of slag and gas generated; and (3) gas compositions (based on the raw material and desired hot metal quality). The model helps in predicting the variations in process parameters with respect to the (1) degree of metallization and (2) post-combustion ratio for given raw material conditions. In general reduction in coal, flux, and oxygen, the requirement is concomitant with an increase in the degree of metallization and post-combustion ratio. The model reported here has been benchmarked using industrial data obtained from the JSW Steel Plant, India.

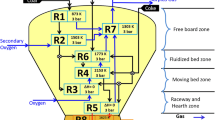

(Adapted from Gudenau et al.[40])

Similar content being viewed by others

Abbreviations

- THM:

-

1 ton of hot metal

- n b a :

-

Amount (in kg-mole) of any “a” in “b”, per kg-mole of Fe

- p b a :

-

Composition of any “a” in “b” (in wt pct)

- M a :

-

Moisture content in “a”

- X :

-

Degree of metallization (in mol pct)

- pcr:

-

Post-combustion ration (in vol pct)

- ΔG :

-

Gibbs-free energy (kJ)

- Bc :

-

Slag basicity

- B :

-

Actual basicity

- T :

-

Temperature (K)

- ΔH m :

-

Heat of mixing per kg-mole of Fe (kJ)

- ΔH s :

-

Sensible heat per kg-mole of Fe (kJ)

- ΔH f :

-

Heat of formation per kg-mole of Fe (kJ)

- ΔH e :

-

Heat of endothermic reaction per kg-mole of Fe (kJ)

- coal:

-

Coal

- L:

-

Limestone

- D:

-

Dolomite

- HM:

-

Hot metal

- slag:

-

Slag

- ore:

-

Ore

- sg:

-

Surplus gas

- tg:

-

Top gas

- pc:

-

Post-combustion

- mg:

-

Gas from the melter gasifier

- r:

-

Reducing gas

- MG:

-

Melter gasifier

- DVC:

-

Devolatization of coal

- sp:

-

Supplied

- dem:

-

Demanded

- o:

-

Output

- A:

-

Active

References

A. Hasanbeigi, M. Arens, and L. Price, Renew: Sustain. Energy Rev., 2014, vol. 33, pp. 645-58.

T. Kuramochi, A. Ramírez, W. Turkenburg, and A. Faaij: Prog. Energy Combust. Sci., 2012, vol. 38, pp. 87-112.

X. L. Zhou and Z. N. Du: Adv. Mater. Res., 2013, vol. 774-6, pp. 1430-3.

J. K. Wright, I. F. Taylor, and D. K. Philp: Miner. Eng., 1991, vol. 4, pp. 983-1001.

M.K. Shin, J.K. Yoon, and M. Tokuda: ISIJ Int., 1993, vol. 33, pp. 385-90.

S. C. Lee, M. K. Shin, S. Joo, and J. K. Yoon: ISIJ Int., 1999, vol. 39, pp. 319-28.

S.C. Lee, M.K. Shin, S. Joo, and J.K. Yoon: ISIJ Int., 2000, vol. 40, pp. 1073-9.

S. Pal and A. K. Lahiri: Metall. Mater. Trans. B, 2003, vol. 34, pp. 103-14.

S. Pal and A. K. Lahiri: ISIJ Int., 2006, vol. 46, p. 58.

S. Pal and A. K. Lahiri: Metall. Mater. Trans. B, 2003, vol. 34, pp. 115-9.

S. Wu, J. Xu, S. Yang, Q. Zhou, and L. Zhang: ISIJ Int., 2010, vol. 50, pp. 1032-9.

S. Wu, J. Xu, J.I. Yagi, X. Guo, and L. Zhang: ISIJ Int., 2011, vol. 51, pp. 1344-52.

J. Xu, S. Wu, M. Kou, and K. Du: ISIJ Int., 2013, vol. 53, pp. 576-82.

M. Kou, S. Wu, K. Du, W. Shen, J. Sun, and Z. Zhang: ISIJ Int., 2013, vol. 53, pp. 1002-9.

M. Kou, S. Wu, W. Shen, K. Du, L. Zhang, and J. Sun: ISIJ Int., 2013, vol. 53, pp. 2080-9.

M. Kou, S. Wu, K. Du, W. Shen, X. Ma, M. Chen, and B. Zhao, JOM, 2015, vol. 67, pp. 459-66.

M. Kou, S. Wu, G. Wang, B. Zhao, and Q. Cai: Steel Res. Int., 2015, vol. 86, pp. 686-94.

H. Zhou, Z.G. Luo, T. Zhang, Y. You, Z.S. Zou, and Y. Shen: ISIJ Int., 2016, vol. 56, pp. 245-54.

M.H. Bai, S.F. Han, W.Y. Zhang, K. Xu, and H. Long: Ironmak. Steelmak. 2016, pp. 1–7.

Q. Hou, J. Li, and A. Yu: Steel Res. Int., 2015, vol. 86, pp. 626-35.

W. Ying, Y. Sun, Z. Luo, and Z. Zou: Adv. Mater. Res., 2011, vol. 287-90, pp. 827-30.

S. Sarkar and G. S. Gupta: Metall. Mater. Trans. B, 2007, vol. 38, pp. 965-75.

G. Pan, X.L. Liu, and Z. Wen: Ironmak. Steelmak., 2013, vol. 40, pp. 255-62.

J. Sun, Z. Luo, and Z. Zou: Powder Technol., 2015, vol. 281, pp. 159-66.

S. C. Barman, K. P. Mrunmaya, and M. Ranjan: J. Iron Steel Res. Int., 2011, vol. 18, pp. 20-4.

H.F. Li, Z.G. Luo, Z.S. Zou, J.J. Sun, L.H. Han, and Z.X. Di: J. Iron Steel Res. Int., 2012, vol. 19, pp. 36-42.

B. Srivastava, S. K. Roy, and P. K. Sen: Metall. Mater. Trans. B, 2010, vol. 41, pp. 935-9.

O. Almpanis-Lekkas, B. Weiss, and W. Wukovits: J. Clean. Prod., 2015, pp. 1–11.

P. Sen, C. Biswas, P. Das, and G. G. Roy: Trans. Institutions Min. Metall. Sect. C Miner. Process. Extr. Metall., 2015, vol. 124, pp. 175-83.

A. Kadrolkar, S. K. Roy, and P. K. Sen: Metall. Mater. Trans. B, 2012, vol. 43, pp. 173-85.

X. Liu, G. Pan, G. Wang, and Z. Wen: Ener. Fuels, 2011, vol. 25, pp. 5729-35.

G. Pan, X.L. Liu, and Z. Wen: Adv. Mater. Res., 2011, vol. 228-9, pp. 930-6.

G. Pan, Z. Wen, X. L. Liu, Y. K. Li, K. C. Zheng, and W. F. Wu: Ironmak. Steelmak., 2015, vol. 42, pp. 489-97.

K. Du, S. Wu, M. Kou, W. Shen, and Z. Zhang: Steel Res. Int., 2014, vol. 85, pp. 466-76.

L.H. Han, Z.-G. Luo, H. Zhou, Z.-S. Zou, and Y.-Z. Zhang: J. Iron Steel Res. Int., 2015, vol. 22, pp. 304-10.

S. C. Koria, M. K. Barui, and L. K. Pandey: Scand. J. Metall., 1999, vol. 28, pp. 17-24.

S. C. Koria and M. K. Barui: Ironmak. Steelmak., 2000, vol. 27, pp. 348-54.

Y. Qu, Z. Zou, and Y. Xiao: ISIJ Int., 2012, vol. 52, pp. 2186-93.

R. J. Fruehan, K. Ito, and B. Ozturk: Steel Res., 1989, vol. 60, pp. 129-37.

H. W. Gudenau, D. Senk, S. Wang, K. De Melo Martins, and C. Stephany: ISIJ Int., 2005, vol. 45, pp. 603-8.

Acknowledgments

The authors would like to acknowledge JSW Steel Ltd., Toranagallu, Bellary, India, for providing the plant data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 23, 2017.

Rights and permissions

About this article

Cite this article

Srishilan, C., Shukla, A.K. Static Thermochemical Model of COREX Melter Gasifier. Metall Mater Trans B 49, 388–398 (2018). https://doi.org/10.1007/s11663-017-1147-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1147-x