Abstract

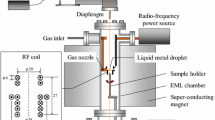

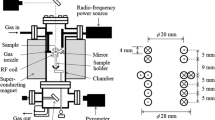

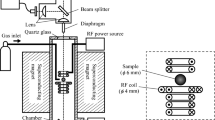

The thermal conductivity of molten Cu-Co alloy with different compositions around the liquidus line temperature was measured by the periodic laser-heating method using an electromagnetic levitator superimposed with a static magnetic field to suppress convection in a levitated droplet sample. During the measurement, a static magnetic field of 10 T was applied to the levitated droplet. To confirm that the strength of the static magnetic field was sufficient to suppress convection in the droplet, numerical simulations were performed for the flow and thermal fields in an electromagnetically levitated droplet under a static magnetic field, and moreover, for the periodic laser-heating method to determine the thermal conductivity. It was found that the thermal conductivity of molten Cu-Co alloy increased gradually with increasing Cu composition up to 80 at. pct, beyond which it increased markedly and reached that of pure Cu. In addition, it was found that the composition dependence of the thermal conductivity can be explainable by the Wiedemann–Franz law.

Similar content being viewed by others

References

Y. Nakagawa: Acta Metall. Mater., 1958, vol. 6, pp. 704–11.

X. Song, S.W. Mahon, R.F. Cochrane, B.J. Hickey, and M.A. Howson: Mater. Lett., 1997, vol. 31, pp. 261–66.

I. Yamauchi, N. Ueno, M. Shimaoka, and I. Ohnaka: J. Mater. Sci., 1998, vol. 33, pp. 371–78.

C.D. Cao, G.P. Gorler, D.M. Herlach, and B. Wei: Mater. Sci. Eng. A, 2002, vol. 325, pp. 503–10.

C.D. Cao, D.M. Herlach, M. Kolbe, G.P. Gorler, and B. Wei: Scripta Mater., 2003, vol. 48, pp. 5–9.

L. Battezzati, S. Curiotto, E. Johnson, and N.H. Pryds: Mater. Sci. Eng. A, 2007, vol. 449–451, pp. 7–11.

Y. Baba, T. Inoue, K. Sugioka, H. Kobatake, H. Fukuyama, M. Kubo, and T. Tsukada: Meas. Sci. Technol., 2012, vol. 23, 045103.

T. Nishi, H. Shibata, Y. Waseda, and H. Ohta: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2801–07.

H. Kobatake, H. Fukuyama, I. Minato, T. Tsukada, and S. Awaji: Appl. Phys. Lett., 2007, vol. 90, p. 094102.

T. Tsukada, H. Fukuyama, and H. Kobatake: Int. J. Heat Mass Transf., 2007, vol. 50, p. 3054–61.

H. Fukuyama, H. Kobatake, K. Takahashi, I. Minato, T. Tsukada, and S. Awaji: Meas. Sci. Technol., 2007, vol. 18, pp. 2059–66.

H. Kobatake, H. Fukuyama, I. Minato, T. Tsukada, and S. Awaji: J. Appl. Phys., 2008, vol. 104, p. 054901.

H. Fukuyama, K. Takahashi, S. Sakashita, H. Kobatake, T. Tsukada, and S. Awaji: ISIJ Int., 2009, vol. 49, pp. 1436–42.

H. Kobatake, H. Fukuyama, T. Tsukada, and S. Awaji: Meas. Sci. Technol., 2010, vol. 21, p. 025901.

K. Sugie, H. Kobatake, M. Uchikoshi, M. Isshiki, K. Sugioka, T. Tsukada, and H. Fukuyama: Jpn. J. Appl. Phys., 2011, vol. 50, p. 11RD04.

J. Brillo, I. Egry, and T. Matsushita: Int. J. Mater. Res., 2006, vol. 97, pp. 1526–32.

T. Kekesi, M. Uchikoshi, K. Mimura, and M. Isshiki: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 573–82.

M. Uchikoshi, H. Shibuya, J. Imaizumi, T. Kekesi, K. Mimura, and M. Isshiki: Metall. Mater. Trans. B, 2010, vol. 41, pp. 448–55.

T. Tsukada, K. Sugioka, T. Tsutsumino, H. Fukuyama, H. Kobatake: Int. J. Heat Mass Transf., 2009, vol. 52, pp. 5152–57.

K. Sugioka, T. Tsukada, H. Fukuyama, H. Kobatake, and S. Awaji: Int. J. Heat Mass Transf., 2010, vol. 53, pp. 4228–32.

Y. Baba, K. Sugioka, M. Kubo, T. Tsukada, K. Sugie, H. Kobatake, and H. Fukuyama: J. Chem. Eng. Jpn, 2011, vol. 44, pp. 321–27.

R.A. Eichel and I. Egry: Z. Metallkd., 1999, vol. 90, pp. 371–75.

M.J. Assael, A.E. Kalyva, and K.D. Antoniadis: J. Phys. Chem. Ref. Data, 2010, vol. 39, p. 033105.

W.F. Gale and T.C. Totemeier: Smithells Metals Reference Book, 8th ed., Elsevier, Inc., Oxford, 2004.

S. Ueno, Y. Nakamura, K. Sugioka, M. Kubo, T. Tsukada, M. Uchikoshi, and H. Fukuyama: Int. J. Thermophys., 2017, vol. 38, p. 16.

F. Guo, T. Lu, J. Qin, H. Zheng, and X. Tian: Physica B, 2012, vol. 407, pp. 4108–13.

NIST-JANAF Thermochemical Tables, 4th ed., American Chemical Society and American Institute of Physics for the National Institute of Standards and Technology, New York, 1998.

G. Pottlacher: J. Noncryst. Solids, 1999, vol. 250–252, pp. 177–81.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 16, 2017.

Rights and permissions

About this article

Cite this article

Nakamura, Y., Takahashi, R., Shoji, E. et al. Thermal Conductivity Measurement of Molten Cu-Co Alloy Using an Electromagnetic Levitator Superimposed with a Static Magnetic Field. Metall Mater Trans B 48, 3213–3218 (2017). https://doi.org/10.1007/s11663-017-1103-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1103-9