Abstract

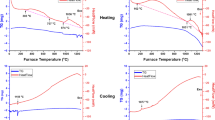

Oxidation process plays an important role in producing sufficiently strong ferrous pellets for blast furnace, and the oxidation behavior of pellet feed greatly affects the quality of pellets. As a supplementary research to earlier published work, the present study fixes its particular attention on the fundamental oxidation behavior of a high FeO South African chromite concentrate in comparison to that of typical magnetite concentrate using differential scanning calorimetry, X-ray diffraction analysis, and thermogravimetry at various temperatures ranging from 473 K to 1273 K (200 °C to 1000 °C). The reaction mechanism and phase transformation during the oxidation process of chromite spinel is further explained by thermodynamics calculation performed by FactSage software. Besides, routine laboratory preheating–roasting test of single ore pellets is also conducted to reveal the relevance of oxidizability to the consolidation of pellets. The results show that the chromite spinel possesses much poorer oxidizability than magnetite, usually accompanying complex phase transformations via a preferential nucleation of Fe-rich sesquioxide from the chromite spinel matrix at low temperatures and thereafter the formation of Cr-rich sesquioxide on the substrate of Fe-rich phase at high temperatures. The oxidation of chromite spinel is inferior to that of magnetite from the viewpoint of thermodynamics and dynamic kinetics. Good inherent oxidizability of raw materials is found to have a positive effect on the induration process of pellet.

Similar content being viewed by others

References

L.A. Cramer, J. Basson, and L.R. Nelson: J. S. Afr. I. Min. Metall., 2004, vol. 104, pp. 517–27.

J. Daavittila, M. Honkaniemi, and P. Jokinen: J. S. Afr. I. Min. Metall., 2004, vol. 104, pp. 541–9.

D.Q. Zhu, C.C. Yang, J. Pan, and Y. Zhong: in 6th International Symposium on High-Temperature Metallurgical Processing, T. Jiang, J.Y. Hwang, G.R.F.A.F.O. Yücel, X. Mao, H.Y. Sohn, N. Ma, P.J. Mackey, and T.P. Battle, eds., Wiley, Hoboken, NJ, 2015, p. 139.

D.Q. Zhu, C.C. Yang, J. Pan, Q. Zhang, B.J. Shi and F. Zhang: Metall. Mater. Trans. B, 2016, 47B, p. 1010-23.

D. Papanastassiou and G. Bitsianes: Metall. Mater. Trans. B, 1973, vol. 4, pp. 487-96.

J.R. Wynnyckyj and T.Z. Fahidy: Metall. Trans., 1974, vol. 5, pp. 991-9.

Y.M. Zhang: Theory and Technology of Iron Ore Pelletizing, 1st ed., Metallurgical Industrial Press, Beijing, 1997, pp. 95–130 (in Chinese)

B. Gillot, R.M. Benloucif, F. Jemmali: J. Mater. Sci., 1984, vol. 19, pp. 3806-13.

B. Gillot, F. Jemmali: J. Mater. Sci., 1986, vol. 21, pp. 4436-42.

J.P. Sanders, P.K. Gallagher: Thermochim. Acta, 2003, vol. 406, pp. 241-3.

E.R. Monazam, R.W. Breault, and R. Siriwardane: Lnd. Eng. Chem. Res., 2014, vol. 53, pp. 13320-8.

B. Gillot, J.F. Ferriot, G. Dupré, A. Roussat: Mater. Res. Bull., 1976, vol. 11, pp. 843-9.

B. Gillot, F. Bouton, F. Chassagneux: Mater. Res. Bull., 1980, vol. 15, pp. 1-7.

S. Sarkar, J. Ghose: J. Therm. Anal., 1990, vol.36, pp. 2593-9.

J.M.G. Amores, V.S. Escribano, G. Busca: Mater. Chem. Phys., 1999, vol. 60, pp. 168-76.

V.D. Tathavadkar, M.P. Antony, A. Jha: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 76-84.

S.S. Ramos, A.D. Carbó, J.G. Adelantado, J.P. Vicente, F.M. Algarra: Thermochim. Acta, 2008, vol. 476, pp. 11-9.

X.L. Liang, Y.H. Zhong, S.Y. Zhu, H.P. He, P. Yuan, J. Zhu, J. Zheng: Solid State Sci., 2013, vol. 15, pp. 115-22.

Y.W. Li: Ph.D Dissertation, Shanghai University, 2010, p. 174–77 (in Chinese)

D.Q. Zhu, Y.H. Luo, J. Pan, and W.T. Zhou: Metal Mine, 2011, pp. 89–93 (in Chinese)

G.Z. Qiu, D.Q. Zhu, J. Pan, C.A. Wang, Y.F. Guo, T. Jiang, C.F. Hu, J. Clout, F.H. Shu: ISIJ Int., 2004, vol. 44, pp. 69-73.

J. Szekely, J.W. Evans, H.Y. Sohn: Gas-solid Reactions, Academic Press, New York, 1976, vol. 3, pp. 73-104.

J.Y. Fu, Y.T. Li, C.W. Jiang, L.Q. Wang: J. Cent. South Univ. (Science and Technology), 2004, vol. 35, pp. 950-4. (in Chinese)

R.Q. Liang, S. Yang, F.S. Yan, J.C. He: J. Iron Steel Res. Int., 2013, vol. 20, pp. 16-20.

H.Q. Tang, X.M. Guo, S.B. Zhang, and Z.C. Guo: J. Iron Steel Res., 2000, vol. 12, pp. 1 (in Chinese)

J.H. Liu, J.Y. Zhang, and T.P. Zhou: J. Iron Steel Res., 2000, vol. 34, pp. 5 (in Chinese)

E.R. Schemidt and F.H.S. Vermaas: Am. Mineral., 1955, vol. 40, pp. 422-31.

A.C.D. Chaklader and G.R. Blair: J. Therm. Anal., 1970, vol. 2, pp. 165-79.

J.P. Sanders, P.K. Gallagher: J. Therm. Anal. Calorim., 2003, vol. 72, pp. 777-789.

R.G. Richards and J. White: Trans. Br. Ceram. Soc., 1954, vol. 53, pp. 233-70.

H. Schmalzried: Chemical Kinetics of Solids, VCH, Cambridge, 1995, pp. 19-42.

K. Huang: Solid State Physics, Peking University Press, Beijing, 2013, pp. 60–80 (in Chinese)

C. Kittel: Introduction to Solid State Physics, John Wiley & Sons, Inc., Hoboken, NJ, 2005, pp. 584-618.

P.K. Gallagher, E.M. Gyorgy, and H.E. Bair: J. Chem. Phys. 1979, vol. 71, pp. 830-5.

M.D. Osborne, M.E. Fleet, G.M. Bancroft: Contrib. Mineral Petrol., 1981, vol. 77, pp. 251-5.

R. Sun: J. Chem. Phys., 1958, vol. 28, pp. 290-3.

J.S. Armijo: Oxid. Met., 1969, vol. 1, pp. 171-98.

J. Vaari: Solid State Ionics, 2015, vol. 270, pp. 10-7.

A.A. Yaremchenko, A.V. Kovalevsky, E.N. Naumovich, V.V. Kharton, J.R. Frade: Solid State Ionics, 2011, vol. 192, pp. 252-8.

J. Töpfer, S. Aggarwal, R. Dieckmann: Solid State Ionics, 1995, vol. 81, pp. 251-66.

K.D. Becker and V.V. Wurmb: Hyperfine Interact., 1990, vol. 56, pp. 1431-6.

Z.Q. Song: Master thesis, Central South University of Technology, 2000, pp. 27–48 (in Chinese)

J.R. Wynnyckyj and W.A. Mccurdy: Metall. Trans., 1974, vol. 5, pp. 2207-15.

S.P.E. Forsmo, S.E. Forsmo, P.O. Samskog, B.M.T. Björkman: Powder Technol., 2008, vol. 183, pp. 247-59.

V. Strezov, T.J. Evans, V. Zymla, L. Strezov: Int. J. Miner. Process., 2011, vol. 100, pp. 27-32.

Acknowledgments

The authors are thankful for financial supports from the National Science Foundation of China (No. 51474161) and Hunan Provincial Co-innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources. The authors also wish to express their gratitude to the School of Materials Science and Engineering in Central South University, which provides the facilities to do the measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 20, 2014.

Rights and permissions

About this article

Cite this article

Zhu, D., Yang, C., Pan, J. et al. Comparison of the Oxidation Behaviors of High FeO Chromite and Magnetite Concentrates Relevant to the Induration of Ferrous Pellets. Metall Mater Trans B 47, 2919–2930 (2016). https://doi.org/10.1007/s11663-016-0770-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0770-2