Abstract

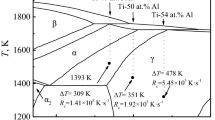

This paper investigates amorphous phase formation and rapid solidification characteristics of a CoCr alloy. High cooling rate and high undercooling-induced rapid solidification of the alloy was achieved by impulse atomization in helium atmosphere. Two atomization experiments were carried out to generate powders of a wide size range from liquid CoCr at two different temperatures. Amorphous fraction and kinetic crystallization properties of impulse atomized powders were systematically quantified by means of differential scanning calorimetry. In addition, different but complementary characterization tools were used to analyze the powders microstructures. The fraction of amorphous phase within the investigated powders is found to be promoted by high cooling rate or smaller powder size. The critical cooling rate for amorphous phase formation, which is influenced by the oxygen content in the melt, is found to be ~3 × 104 K s−1 and corresponds to a 160-µm-diameter powder atomized in helium. Hardness of the powders is found to follow a trend that is described by the Hall–Petch relation when a relatively high fraction of crystalline structures is present and decreases with the fraction of amorphous phase.

Similar content being viewed by others

References

Klement W, Willens RH, Duwez P. Nature. (1960) 187: 869–870.

Chen, H.S., D.Turnbull. Appl. Phys. Lett. 1967, 10 (10), 284.

H.-W. Kui, A.L. Greer, and D. T. Appl. Phys. Lett. 1993, 63, 2342.

.A. Inoue, N Nishiyama, H.M Kiruma. Mater. Trans. JIM 1997, 38, 179-83.

(5) Q. S. Zhang,, D. Y. Guo, A. M. Wang, H. F. Zhang, B. Z. D. and Z. Q. H. Intermetallics 2002, 10, 1197–1201.

(6) Y. Zhang, D. Q. Zhao, R. J. W. and W. H. W. Acta Mater. 2003, 51, 1971–1979.

(7) Suryanarayana, C.; Inoue, A. Int. Mater. Rev. 2013, 58 (3), 131–166.

(8) Inoue, A.; Shen, B. L.; Chang, C. T. Intermetallics 2006, 14 (8-9), 936–944.

(9) Henein, H. Mater. Sci. Eng. A 2002, 326 (1), 92–100.

(10) Mullis, A. M.; Bigg, T. D.; Adkins, N. J. J. Alloys Compd. 2015, 648, 139–148.

Prasad, A.; Mosbah, S.; Henein, H.; Gandin, C.-A. ISIJ International. 2009, 49: 992–999.

(12) Wiskel, J. B.; Henein, H.; Maire, E. Can. Metall. Q. 2002, 41 (1), 97–110.

13.Wiskel, J. B.; Navel, K.; Henein, H.; Maire, E. Canadian Metallurgical Quarterly; 2002; 41: 193–204.

(14) Gandin, C.-A.; Mosbah, S.; Volkmann, T.; Herlach, D. M. Acta Mater. 2008, 56 (13), 3023–3035.

(15) Ciftci, N. Ellendt, N.Von Bargen, R.Henein, H. Mädler, L.Uhlenwinkel, V. J. Non. Cryst. Solids 2014, 394-395, 36–42.

(16) Minić, D., Gavrilović, A., Angerer, P., Minić, D., & Maričić, A. J. Alloys Compd. 2009, 482, 502–507.

17.Fraczyk, A. Tech. Sci. 2011, 1:1-208.

(18) Lee, K. S., & Lee, Y. S. 2012 2012, 5, 2472–2478.

(19) Wang, H., Gao, Y., Ye, Y., Min, G., Chen, Y., & Teng, X. J. Alloys Compd. 2003, 353, 200–206.

20.Hansen, N. Scripta Mater. 2004, 51, 801–806.

(21) Meyers, M. A.; Mishra, A.; Benson, D. J. Prog. Mater. Sci. 2006, 51 (4), 427–556.

(22) Takeuchi, S. Scr. Mater. 2001, 44 (8-9), 1483–1487.

(23) Saada, G. Mater. Sci. Eng. A 2005, 400-401 (1-2 SUPPL.), 146–149.

(24) Scattergood, R. O.; Koch, C. C. Scr. Metall. Mater. 1992, 27 (9), 1195–1200.

(25) Gholipour, A.; Shamanian, M.; Ashrafizadeh, F. J. Alloys Compd. 2011, 509 (14), 4905–4909.

(27) Bogno, A-A.; Dahlborg U.; Calvo- Dahlborg M.; Riveros C.; Ciftci, N.; Henein, H., Sediako D.;. J. Non-Cryst. Solids 432 (2016), 466-470.

http://www.stellite.co.uk/ProductsServices/SprayFusePowderWeldPowder/tabid/67/Default.aspx. Accessed 28 Oct 2015.

Acknowledgments

The authors are grateful to the Natural Sciences and Engineering Research Council of Canada (NSERC), KENNAMETAL Inc., and RIEM-NSERC Grant for the collaboration with CanmetMATERIALS.

Author information

Authors and Affiliations

Corresponding author

Additional information

©Her Majesty the Queen in Right of Canada, as represented by the Minister of Natural Resources, 2016.

Manuscript submitted October 31, 2015.

Rights and permissions

About this article

Cite this article

Bogno, AA., Riveros, C., Henein, H. et al. Amorphous Phase Formation Analysis of Rapidly Solidified CoCr Droplets. Metall Mater Trans B 47, 3257–3265 (2016). https://doi.org/10.1007/s11663-016-0635-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0635-8