Abstract

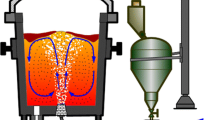

Ladle furnace is a key unit in which various phenomena such as deoxidation, desulfurization, inclusion removal, and homogenization of alloy composition and temperature take place. Therefore, the processes present in the ladle play an important role in determining the quality of steel. Prediction of flow behavior of the phases present in the ladle furnace is needed to understand the phenomena that take place there and accordingly control the process parameters. In this study, first a mathematical model is developed to analyze the transient three-phase flow present. Argon gas bottom-stirred ladle with off-centered plugs has been used in this study. Volume of fluid method is used in a computational fluid dynamics (CFD) model to capture the behavior of slag, steel, and argon interfaces. The results are validated with data from literature. Eye opening and slag–steel interfacial area are calculated for different operating conditions and are compared with experimental and simulated results cited in literature. Desulfurization rate is then predicted using chemical kinetic equations, interfacial area, calculated from CFD model, and thermodynamic data, obtained from the Thermo-Calc software. Using the model, it is demonstrated that the double plug purging is more suitable than the single plug purging for the same level of total flow. The advantage is more distinct at higher flow rates as it leads higher interfacial area, needed for desulfurization and smaller eye openings (lower oxygen/nitrogen pickup).

Similar content being viewed by others

Abbreviations

- ρ :

-

Density of the mixture (kg/m3)

- ρ q :

-

Density of each phase q (steel, slag, argon) (kg/m3)

- κ :

-

Local level of turbulent kinetic energy (m2/s2)

- \( \kappa_{\text{in}} \) :

-

Inlet turbulent kinetic energy (m2/s2)

- ϵ :

-

Local level of turbulent kinetic energy dissipation rate (m2/s3)

- ϵ in :

-

Inlet turbulent kinetic energy dissipation rate (m2/s3)

- μ :

-

Dynamic viscosity of molten steel (kg/ms))

- μ t :

-

Turbulent viscosity of molten steel (kg/ms)

- μ e :

-

Effective viscosity of molten steel (kg/ms)

- \( \alpha_{\text{q}} \) :

-

Volume fraction of particular phase q

- \( \Lambda \) :

-

Average optical basicity of the slag

- \( \Lambda_{i} \) :

-

Optical basicity of individual oxides

- ϵs :

-

Stirring power (W/ton)

- A :

-

Interfacial area between slag and steel (m2)

- (CaO):

-

CaO in the slag

- (CaS):

-

CaS in the slag

- C S :

-

Sulfide capacity of slag

- D plug :

-

Diameter of the plug (m)

- G k :

-

Generation of turbulent kinetic energy due to mean velocity gradient

- G b :

-

Generation of turbulent kinetic energy due to buoyancy

- g :

-

Acceleration due to gravity (m/s2)

- H :

-

Height of liquid steel melt (m)

- k s :

-

Mass transfer rate (m/s)

- k [O] :

-

Equilibrium constant of aluminum oxidation reaction

- L S :

-

Sulfur distribution ratio

- M L :

-

Ratio of slag to steel weights

- NLM:

-

Argon flow rate in Liter/Minute at STP

- N fi :

-

Mole fraction of the particular oxide in the slag

- [O]:

-

Dissolved oxygen in the melt

- [O pct]:

-

Oxygen concentration in the liquid steel melt (wt pct)

- p :

-

Local pressure in the fluid (pa)

- P o :

-

Pressure at the top of the Ladle (atm)

- Pr t :

-

Prandtl number

- q :

-

Phase notations l: Liquid steel, g: argon gas, s: slag

- Q :

-

Argon flow rate (N m3/s)

- [S]:

-

Sulfur composition in the steel melt (wt pct)

- (S):

-

Sulfur content in the slag (wt pct)

- [S]L :

-

Final sulfur content in slag (wt pct)

- [S]0 :

-

Initial sulfur content in slag(wt pct)

- T :

-

Temperature (K)

- t :

-

Time instant (s)

- u i :

-

Velocity component of the fluid (m/s)

- v :

-

Local velocity (m/s)

- V in :

-

Inlet velocity at the plug (m/s)

- V :

-

Volume of steel (m3)

- W st :

-

Weight of liquid steel (ton)

References

J. Aoki, L, Zhang, and B.G. Thomas: 3rd International Congress on Science and Technology of Steel Making, 2005, pp. 319–32.

[2] S. Ganguly and S. Chakraborty: ISIJ International, 2004, vol. 44, No. 3, 537-546.

[3] S. Ganguly and S. Chakraborty: Ironmaking and Steelmaking, 2008, vol. 35, No. 7, 524-530.

[4] S. Joo and R. I. L. Guthrie: Metall. Trans. B, 23B 1992, 765-778.

[5] M. Y. Zhu, I. Inomoto, N. Yamasaki and T. C. Hsiao: ISIJ Int., 1996, vol. 36, no 5, 503-511.

[6] S. Johansen and F. Boysan: Metall. Mater. Trans. B, 1988, vol. 19B, 755-764.

J. Aoki, B. G. Thomas and J. Peter: AISTech, Assoc. Iron Steel Technology, 2005, Warrendale, PA, pp. 1047-1056.

[8] M. Warzecha, J. Jowsa, P. Warzecha and H. Pfeifer: Steel Research Int., 2008, vol. 79, No. 11, 852-860.

[9] M. Madan, D. Satish and D. Mazumdar: ISIJ Int., 2005, vol. 45, No. 5, 677-685.

[10] D. Guo, L. Gu and G. Irons: Appl. Math. Model, 2002, vol. 26, 263-280.

[11] D. Mazumdar, R. Yadav and B. B. Mahato: ISIJ Int., 2002, vol. 42, No. 1, 106-108.

[12] M. R. Davidson: Appl. Math. Model, 1990, vol. 14, pp. 67-76.

[13] H. Turkoglu and B. Farouk: Metall. Trans. B, 1990, vol. 21B, pp. 771-781.

[14] W. Lou and M. Zhu: Metallurgical and Materials Transactions B, 2013, vol 44B, pp 1251-1263.

[15] C. G. Mendez, N. Nigro and A. Cardona: J. Mater. Process. Tech., 2005, vol. 160, pp. 296-305.

[16] J. Mandal, S. Patil, M. Madan and D. Mazumdar: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 479-487.

[17] S. G. A. Brooks, and G. A. Irons: Iron Steel Inst. Jpn. Int., 2003, vol. 43, pp. 262-263.

[18] D. Mazumdar and J. W. Evans: Metall. Mater. Trans. B, 2004, vol. 35B, no 2, pp. 400-404.

[19] K. Krishnapisharody and G. A. Irons: Metall. Mater. Trans. B, 2006, vol. 37B, no.5 pp. 763-772.

[20] K. Krishnapisharody and G. A. Irons: ISIJ International, 2008, vol. 48, pp. 1807-1809.

[21] D. Mazumdar and J. W. Evans: ISIJ Int., 2004, vol. 44, No. 3, pp. 447-461.

[22] D. Mazumdar and R. I. L. Guthrie: ISIJ Int., 1995, vol. 35, No. 1, pp. 1-20.

[23] D. Sichen: Steel research int. 2012, 83, No. 9, pp.825-841

[24] D. Mazumdar and J. W. Evans: “Modelling of steel making process”, p. 175, CRC press Taylor& Francis group, London, 2004.

[25] D. Q. GENG, H. LEI and J. C. HE: ISIJ Int., 2010, vol. 50, No. 11, pp. 1597-1605.

J. Aoki, L. Zhang, and B.G. Thomas: 3rd International Congress on Science & Technology of Steelmaking, Association for Iron & Steel Technology, 2005, pp. 319–32.

[27] J. P. Bellot, V. D. Felice, B. Dussoubs, A. Jardy, S. Hans: Metallurgical and Materials Transactions B, February 2014, vol 45, Issue 1, pp 13-21.

[28] W. Lou and M. Zhu: Metallurgical and Materials Transactions B, June 2013, vol 44B,, pp 762-782.

[29] S. W. P. Cloete, J. J. Eksteen and S. M. Bradshaw: Progress in Computational Fluid Dynamics, an International Journal, 2009, vol. 9, No. 6-7,pp. 345–356.

C. A. Llanos, S. Garcia-Hernandez, J. A. Ramos-Banderas, J. de Barreto and G. Solorio-Diaz: ISIJ Int., 2010, vol. 50, No 3, pp. 396-402.

[31] B. Li, H. Yin, C. Q. Zhou and F. Tsukihashi: ISIJ Int., 2008, vol. 48, No 12, pp. 1704-1711.

[32] H. Liu, Z. Qi, M. Xu: Steel Research Int., 2011, vol. 82, No 4, pp. 440-458.

[33] S. W.P. Cloete, J. J. Eksteen, S. M. Bradshaw: Minerals Engineering, 2013, vol. 46–47, pp. 16-24.

[34] A. Huang, H. Harmuth, M. Doletschek, S. Vollmann, and X. Feng: Steel Res. Int., 2015, vol. 86, No 12, pp. 1147-454.

[41] E.T. Turkdogan: Fundamentals of steelmaking, p. 245, The Institute of materials, London, 1996.

[35] L. Jonsson, D. Sichen and P. Jonsson: ISIJ Int., 1998, vol. 38, No 3, pp. 260-267.

[36] M.A.T. Andersson, L. T. I. Jonsson and P. G. Jonsson: ISIJ Int., 2000, vol. 40, no 11, pp. 1080-1088.

[37] W. Lou, M. Zhu: ISIJ Int., 2015, vol. 55, No. 5, pp. 961-969.

[38] W. Lou, M. Zhu: Metallurgical and Materials Transactions B, October 2014, vol 45, Issue 5, pp 1706-1722.

[39] A. Ghosh: Secondary steelmaking, principles and applications, p. 200, CRC Press LLC, New York 2001.

R.J. Fruehan: The Making, Shaping and Treating of Steel, 11th ed., The AISE Steel Foundation, Pittsburgh, 1998, p. 661.

ANSYS® Academic Research, Fluent, Release 15.

M.B. Goldschmit and G.N. Venturini: European Congress on Computational Methods in Applied Sciences and Engineering, Jyvaskyla, 2004.

[44] L. Zhang: JOM, September 2012, Vol 64, Issue 9, pp. 1059-1062.

Z. Zhang: PhD thesis, 2010, Department of Materials Science and Engineering, Royal Institute of Technology, Stockholm, Sweden.

E. Pretorius: Fundamentals of EAF and Ladle Slags and Ladle Refining Principles, Bakers Refractories.

[47] Z. Slovic, K T. Raic, L. Nedeljkovic, T. V.Husovic: Materials and technology, 2012, vol. 46, pp. 683-688.

[48] M. Andersson, P.G. Jonsson and M.M.Nzotta: ISIJ Int., 1999, vol. 40, No. 11, pp. 1140-1149.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 15, 2015.

Rights and permissions

About this article

Cite this article

Singh, U., Anapagaddi, R., Mangal, S. et al. Multiphase Modeling of Bottom-Stirred Ladle for Prediction of Slag–Steel Interface and Estimation of Desulfurization Behavior. Metall Mater Trans B 47, 1804–1816 (2016). https://doi.org/10.1007/s11663-016-0620-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0620-2