Abstract

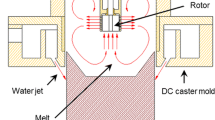

Achieving uniform grain size in ingots is challenging in traditional direct chill (DC) casting. The thermal conditions during solidification often result in smaller grain size at the edge of the ingot compared to the center, leading to grain size inhomogeneity even in centimeter-scale samples. In this study, a low-flow pouring technique with the addition of grain refiner is employed to create similar thermal conditions from the edge to the center of the ingot during solidification, resulting in a homogeneous ingot. The grain size at the center of the prepared ingot consistently matches it at the edge. Finite element analysis confirms that low-flow pouring provides suitable thermal conditions for ensuring homogenous grains. Additionally, based on experimental results, a novel analytical model is proposed to precisely identify all active nucleation substrates. The grain size predicted by the proposed model aligns well with the experimental results, outperforming previous models. Our experimental and analytical results provide valuable guidance for the production of homogeneous ingots on an industrial scale.

Similar content being viewed by others

Data availability

The raw data will be available from the corresponding author upon reasonable request.

References

M.A. Easton, M. Qian, A. Prasad, and D.H. StJohn: Curr. Opin. Solid State Mater. Sci., 2016, vol. 20, pp. 13–24.

D.G. Eskin: Physical Metallurgy of Direct Chill Casting of Aluminum Alloys, CRC Press, Boca Raton, 2008.

B.S. Murty, S.A. Kori, and M. Chakraborty: Int. Mater. Rev., 2002, vol. 47, pp. 3–29.

W. Kurz, D.J. Fisher, and M. Rappaz: Fundamentals of Solidification, 5th edn. (Trans Tech Publications Ltd, Switzerland, 2023), pp. 7–9.

Z. Fan, Y. Wang, Y. Zhang, T. Qin, X.R. Zhou, G.E. Thompson, T. Pennycook, and T. Hashimoto: Acta Mater., 2015, vol. 84, pp. 292–304.

F. Yu, X.J. Wang, T.J. Huang, and D.Y. Chao: Materials, 2021, vol. 14, p. 6705.

T.E. Quested and A.L. Greer: Acta Mater., 2004, vol. 52, pp. 3859–68.

M.A. Easton and D.H. StJohn: Mater. Sci. Eng. A, 2008, vol. 486, pp. 8–13.

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans, and D.J. Bristow: Acta Mater., 2000, vol. 48, pp. 2823–35.

Y. Jia, S. Wang, and D. Shu: J. Alloys Compd., 2020, vol. 821, p. 153504.

W.A. Tiller, K.A. Jackson, J.W. Rutter, and B. Chalmers: Acta Mater., 1953, vol. 1, pp. 428–37.

D. Shu, B. Sun, J. Mi, and P.S. Grant: Acta Mater., 2011, vol. 59, pp. 2135–44.

D.H. StJohn, M. Qian, M.A. Easton, and P. Cao: Acta Mater., 2011, vol. 59, pp. 4907–21.

J.A. Spittle: Int. Mater. Rev., 2013, vol. 51, pp. 247–69.

A. Prasad, L. Yuan, P. Lee, M. Patel, D. Qiu, M. Easton, and D. StJohn: Acta Mater., 2020, vol. 195, pp. 392–403.

X. Yijiang, D. Casari, R.H. Mathiesen, and Y. Li: Acta Mater., 2018, vol. 149, pp. 312–25.

A.L. Greer: J. Chem. Phys., 2016, vol. 145, p. 211704.

A.L. Greer, P.S. Cooper, M.W. Meredith, W. Schneider, P. Schumacher, J.A. Spittle, and A. Tronche: Adv. Eng. Mater., 2003, vol. 5, pp. 81–91.

M. Zhang, P. Kelly, M. Easton, and J. Taylor: Acta Mater., 2005, vol. 53, pp. 1427–38.

D. Qiang and Y. Li: Acta Mater., 2014, vol. 71, pp. 380–89.

M. Sun, M.A. Easton, D.H. StJohn, W. Guohua, T.B. Abbott, and W. Ding: Adv. Eng. Mater., 2013, vol. 15, pp. 373–78.

Y. Han, K. Li, J. Wang, D. Shu, and B. Sun: Mater. Sci. Eng. A, 2005, vol. 405, pp. 306–12.

Y. Han, Da. Shu, J. Wang, and B. Sun: Mater. Sci. Eng. A, 2006, vol. 430, pp. 326–31.

M. Qian, P. Cao, M.A. Easton, S.D. McDonald, and D.H. StJohn: Acta Mater., 2010, vol. 58, pp. 3262–70.

I. Maxwell and A. Hellawell: Acta Metall., 1975, vol. 23, pp. 229–37.

P. Galenko and S. Sobolev: Phys. Rev. E, 1997, vol. 55, pp. 343–52.

K. Eckler, R.F. Cochrane, D.M. Herlach, B. Feuerbacher, and M. Jurisch: Phys. Rev. B, 1992, vol. 45, pp. 5019–22.

J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57–63.

L. Yuan and P.D. Lee: Model. Simul. Mater. Sci. Eng., 2010, vol. 18, p. 055008.

R.C. Atwood and P.D. Lee: Acta Mater., 2003, vol. 51, pp. 5447–66.

A. Prasad, L. Yuan, P.D. Lee, and D.H. StJohn: Acta Mater., 2013, vol. 61, pp. 5914–27.

T.E. Quested and A.L. Greer: Acta Mater., 2005, vol. 53, pp. 4643–53.

Xu. Yijiang, D. Casari, Du. Qiang, R.H. Mathiesen, L. Arnberg, and Y. Li: Acta Mater., 2017, vol. 140, pp. 224–39.

W. Kurz, M. Rappaz, and R. Trivedi: Int. Mater. Rev., 2020, vol. 66, pp. 30–76.

W. Kurz, C. Bezençon, and M. Gäumann: Sci. Technol. Adv. Mater., 2001, vol. 2, pp. 185–91.

M. Rettenmayr: Int. Mater. Rev., 2013, vol. 54, pp. 1–7.

F.C. Robles Hernandez, M.B. Djurdjevic, W.T. Kierkus, and J.H. Sokolowski: Mater. Sci. Eng.: A, 2005, vol. 396, pp. 271–76.

A.M. Mitrašinović and F.C. Robles Hernández: Mater. Sci. Eng.: A, 2012, vol. 540, pp. 63–69.

M.J. Bermingham, D.H. StJohn, J. Krynen, S. Tedman-Jones, and M.S. Dargusch: Acta Mater., 2019, vol. 168, pp. 261–74.

D.H. StJohn, M.A. Easton, and M. Qian: in 13th Int. Conf. Alum. Alloys (ICAA), Carnegie Mellon University, Pittsburgh, PA, Wiley, 2012, pp. 1419–24.

Acknowledgments

This work is financially supported by the National Key Research and Development Program of China (No. 2023YFB3406800) and National Natural Science Foundation of China (Nos. 52273230 and 51731007).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, D., Han, Y., Lu, S. et al. Effect of Coupling Low-Flow Pouring with Inoculation on the As-Cast Microstructure of 7055 Alloys. Metall Mater Trans A 55, 1564–1575 (2024). https://doi.org/10.1007/s11661-024-07344-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-024-07344-5