Abstract

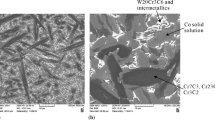

The carburized layer was fabricated on the surface of TA2 pure titanium by pack carburizing. The effects of carburizing agent, carburizing temperature and carburizing time on the thickness of the carburized layer were investigated by scanning electron microscope (SEM) and X-ray diffraction (XRD). The experimental results showed that the carburized layer is composed of TiC phase. After carburized at 1100 °C for 15 hours, the TiC layer has the thickest thickness of 423 ± 0.4 μm. Besides, the growth mechanism and kinetics of the TiC layer were explored. The activation energy of C in the TiC layer during pack carburizing is 87.220 kJ/mol. The wear and corrosion properties of TiC layer were characterized by microhardness, wear tests, and electrochemical experiments. The highest hardness of TiC layer is 1036HV, and the hardness decreases gradually from the TiC layer to matrix. The wear type is abrasive wear with the exfoliation of the TiC layer. Finally, the corrosion properties of the carburized sample were also discussed.

Similar content being viewed by others

References

J.C. Sánchez-López, S. Dominguez-Meister, T.C. Rojas, M. Colasuonno, M. Bazzan, and A. Patelli: Appl. Surf. Sci., 2018, vol. 440, pp. 458–66.

G.Q. Xu and X.K. Shen: Surf. Coat. Technol., 2019, vol. 364, pp. 180–96.

X.Y. Zhang, S. Pfeiffer, P. Rutkowski, M. Makowska, D. Kata, J.L. Yang, and T. Graule: Appl. Surf. Sci., 2020, vol. 520, 146304.

B. Callegari, J.P. Oliveira, R.S. Coelho, P.P. Brito, N. Schell, F.A. Soldera, F. Mücklich, M.I. Sadik, J.L. García, and H.C. Pinto: Mater. Charact., 2020, vol. 162, 110180.

C.A.F. Salvador, E.L. Maia, F.H. Costa, J.D. Escobar, and J.P. Oliveira: Sci. Data, 2022, vol. 9, p. 188.

B. Callegari, J.P. Oliveira, K. Aristizabal, R.S. Coelho, P.P. Brito, L. Wu, N. Schell, F.A. Soldera, F. Mücklich, and H.C. Pinto: Mater. Charact., 2020, vol. 165, 110400.

Y. Liu, R. Sun, W. Niu, T. Zhang, and Y. Lei: Opt Laser. Eng., 2019, vol. 120, pp. 84–94.

F. Ma, J. Zhou, P. Liu, W. Li, X. Liu, D. Pan, W. Lu, D. Zhang, L. Wu, and X. Wei: Mater. Char., 2017, vol. 127, pp. 27–34.

H.Z. Niu, H.R. Zhang, Q.Q. Sun, and D.L. Zhang: Mater. Sci. Eng. A, 2019, vol. 754, pp. 361–69.

Y.P. Lu, D.Y. Qu, Y.H. Duan, and M.J. Peng: Ceram. Int., 2022, vol. 48, pp. 5646–6565.

Y.H. Duan, D. Liu, B.L. He, L.S. Ma, Y.Y. Hu, and X.Q. Li: Philos. Magn. Lett., 2018, vol. 98, pp. 521–26.

Y.P. Lu, D.Y. Qu, Y.H. Duan, and M.J. Peng: Ceram. Int., 2021, vol. 47, pp. 25142–46.

S. Barril, S. Mischler, and D. Landolt: Tribol. Int., 2001, vol. 34, pp. 599–608.

Y.T. Zhao, Z.Q. Fan, Q.Y. Tan, Y. Yin, M.Y. Lu, and H. Huang: Tribol. Int., 2021, vol. 155, 106758.

J. Chen, Z.L. Zhang, G.J. Yang, Z.H. Fang, Z.F. Yang, Z. Li, and G.Y. He: Appl. Surf. Sci., 2020, vol. 513, 145457.

Z.Y. Zhao, P.F. Hui, T. Wang, X. Wang, Y.H. Xu, L.S. Zhong, and M.X. Zhao: J. Alloys Compd., 2018, vol. 745, pp. 637–43.

T.Y. Zhang, J. Wang, Z.Z. Pan, and Q. Tao: Mater. Sci. Eng. A, 2022, vol. 832, 142452.

B. Jamieson, C. Bilin, X. Xie, R. Yang, D.V. Jimmy, K.L. Peter, and J.Z. Steven: Mater. Sci. Eng. A, 2019, vol. 753, pp. 135–45.

Z.L. Li, M.M. Wei, K. Xiao, Z.H. Bai, W. Xue, C.F. Dong, D. Wei, and X.G. Li: Ceram. Int., 2019, vol. 45, pp. 115–21.

J. Lee, D. Lee, M.H. Song, W. Rhee, H.J. Ryu, and S.H. Hong: J. Mater. Sci. Technol., 2018, vol. 34, pp. 1397–1404.

Y.T. Li, K.M. Wang, H.G. Fu, X.Y. Guo, and J. Lin: Appl. Surf. Sci., 2022, vol. 585, 152703.

Y. Yang, M.F. Yan, and Y.X. Zhang: Appl. Surf. Sci., 2019, vol. 479, pp. 482–88.

H.W. Zhao, J.H. Li, S.B. Guo, D.D. Fan, G.H. Liu, and J.T. Li: Ceram. Int., 2017, vol. 43, pp. 6904–09.

X. He, R.G. Song, and D.J. Kong: Opt. Laser Technol., 2013, vol. 219, pp. 339–48.

M.S. Afarani, S. Khorshahian, and M. Sharifitaba: Surf. Coat. Technol., 2013, vol. 219, pp. 94–100.

L. Yong, H. Jiang, C. Gang, and H. Liu: J. Bionic Eng., 2011, vol. 08, pp. 86–89.

C.J. Liao, J.S. Yang, Y.H. He, and X.Z. Ming: J. Alloys Compd., 2015, vol. 619, pp. 221–27.

S. Aich and K.S.R. Chandran: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 3489–98.

L.S. Ma, Y.H. Duan, and P. Li: J. Mater. Eng. Perform., 2017, vol. 26, pp. 4544–55.

G. Kara and G. Purcek: Surf. Eng., 2018, vol. 35, pp. 611–17.

P. Li, D. Liu, W. Bao, L. Ma, and Y. Duan: Ceram. Int., 2018, vol. 44, pp. 18429–37.

T. Hayashi, K. Matsuura, and M. Ohno: Mater. Trans., 2013, vol. 54, pp. 2098–2101.

K. Takato and N. Akio: Mater. Trans., 2019, vol. 60, pp. 2387–91.

Y. Duan, X. Wang, D. Liu, W. Bao, P. Li, and M. Peng: Ceram. Int., 2020, vol. 46, pp. 16380–87.

B.B. Khina, B. Formanek, and I. Solpan: Physica B, 2005, vol. 355, pp. 14–31.

F. Li, X. Yi, J. Zhang, Z. Fan, D. Gong, and Z. Xi: Acta Metall. Sin., 2010, vol. 23, pp. 293–300.

A.G. Vodop’yanov, G.N. Kozhevnikov, and S.V. Baranov: Russ. Chem. Rev., 1988, vol. 57, p. 810.

X. Wang, Z.H. Zhang, Y.Z. Men, X.J. Li, Y.H. Liang, and L.Q. Ren: Opt. Laser Technol., 2020, vol. 126, 106136.

V. Chakkravarthy, J.P. Oliveira, A. Mahomed, N. Yu, P. Manojkumar, M. Lakshmanan, L. Zhang, S. Jerome, T. Ram Prabhu, and R.L. Narayan: Vacuum, 2023, vol. 210, 111872.

Z.Z. Zhang, Y.B. Chen, Y. Zhang, K.W. Gao, L.L. Zuo, Y.S. Qi, and Y. Wei: J. Alloys Compd., 2017, vol. 704, pp. 260–68.

J. Ke, X.B. Liu, M. Wang, J. Liang, Y.S. Luo, and D.Q. Chen: J. Mater. Res. Technol., 2020, vol. 9, pp. 6397–6408.

X.Y. Wang, D.Y. Qu, Y.H. Duan, and M.J. Peng: Ceram. Int., 2022, vol. 48, pp. 12038–47.

H. Dhiflaoui, K. Khlifi, N. Barhoumi, and A.B.C. Larbi: J. Mater. Res. Technol., 2020, vol. 9, pp. 5293–5303.

J. Bisquert, G. Garcia-Belmonte, P. Bueno, E. Longo, and L.O.S. Bulhões: J. Electroanal. Chem., 1998, vol. 452, pp. 229–34.

L. Cheng, R. Jin, D.C. Jiang, J. Zhuang, X.B. Liao, and Q.Q. Zheng: Anal. Chem., 2021, vol. 93, pp. 16401–08.

R. Udhayan and D.P. Bhatt: J. Power Sources, 1996, vol. 452, pp. 103–07.

J.R. Li, Q.T. Jiang, H.Y. Sun, and Y.T. Li: Corros. Sci., 2016, vol. 452, pp. 288–301.

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Grant No. 52261018, the Analysis and Testing Foundation of Kunming University of Science and Technology under Grant No. 2022T20110026.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Feng, Z., Duan, Y. & Peng, M. Growth Kinetics, and Wear and Corrosion Properties of TiC Coatings on Pure Titanium by Carburizing. Metall Mater Trans A 54, 2947–2959 (2023). https://doi.org/10.1007/s11661-023-07069-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07069-x