Abstract

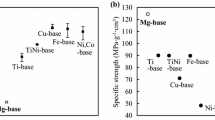

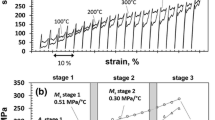

We investigated the effect of aging treatment on the microstructure and superelasticity of Mg–Sc alloy. Transmission electron microscopy observations and tensile tests revealed that aging treatment at 100 °C caused ordering of the parent phase from a disordered bcc (A2) to an ordered bcc (B2) structure and considerably improved the superelasticity at room temperature. The maximum superelastic recovery obtained in an aged bamboo-crystalline sample was 4.6 pct, which is comparable to the conventional shape memory alloys.

Similar content being viewed by others

References

K. Otsuka and K. Shimizu: Int. Metals Rev., 1986, vol. 31, pp. 93–114. https://doi.org/10.1179/imtr.1986.31.1.93.

S. Miyazaki and K. Otsuka: ISIJ Int., 1989, vol. 29, pp. 353–77. https://doi.org/10.2355/isijinternational.29.353.

S. Miyazaki: Shap. Mem. Superelast., 2017, vol. 3, pp. 279–314. https://doi.org/10.1007/s40830-017-0122-3.

H.Y. Kim, J. Fu, H. Tobe, J.I. Kim, and S. Miyazaki: Shap. Mem. Superelast., 2015, vol. 1, pp. 107–16. https://doi.org/10.1007/s40830-015-0022-3.

J. Fu, A. Yamamoto, H.Y. Kim, H. Hosoda, and S. Miyazaki: Acta Biomater., 2015, vol. 17, pp. 56–67. https://doi.org/10.1016/j.actbio.2015.02.001.

K. Endoh, M. Tahara, T. Inamura, and H. Hosoda: Mater. Sci. Eng. A, 2017, vol. 704, pp. 72–76. https://doi.org/10.1016/j.msea.2017.07.097.

S. Li and T.-H. Nam: Intermetallics, 2019, vol. 112, p. 106545. https://doi.org/10.1016/j.intermet.2019.106545.

T. Omori, M. Okano, and R. Kainuma: APL Mater., 2013, vol. 1, p. 032103. https://doi.org/10.1063/1.4820429.

T. Omori, S. Abe, Y. Tanaka, D.Y. Lee, K. Ishida, and R. Kainuma: Scr. Mater., 2013, vol. 69, pp. 812–15. https://doi.org/10.1016/j.scriptamat.2013.09.006.

T. Omori, K. Ando, M. Okano, X. Xu, Y. Tanaka, I. Ohnuma, R. Kainuma, and K. Ishida: Science, 2011, vol. 333, pp. 68–71. https://doi.org/10.1126/science.1202232.

Y. Liu, I. Houver, H. Xiang, L. Bataillard, and S. Miyazaki: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1275–82. https://doi.org/10.1007/s11661-999-0276-5.

Y. Tanaka, Y. Himuro, R. Kainuma, Y. Sutou, T. Omori, and K. Ishida: Science, 2010, vol. 327, pp. 1488–90. https://doi.org/10.1126/science.1183169.

R. Kainuma, S. Takahashi, and K. Ishida: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2187–95. https://doi.org/10.1007/BF02651873.

Y. Sutou, N. Koeda, T. Omori, R. Kainuma, and K. Ishida: Acta Mater., 2009, vol. 57, pp. 5759–70. https://doi.org/10.1016/j.actamat.2009.08.011.

Y. Sutou, T. Omori, R. Kainuma, and K. Ishida: Acta. Mater., 2013, vol. 61, pp. 3842–50. https://doi.org/10.1016/j.actamat.2013.03.022.

Y. Sutou, T. Omori, K. Yamauchi, N. Ono, R. Kainuma, and K. Ishida: Acta Mater., 2005, vol. 53, pp. 4121–33. https://doi.org/10.1016/j.actamat.2005.05.013.

Y. Sutou, T. Omori, R. Kainuma, and K. Ishida: Mater. Sci. Technol., 2008, vol. 24, pp. 896–901. https://doi.org/10.1179/174328408X302567.

Y. Ogawa, D. Ando, Y. Sutou, and J. Koike: Science, 2016, vol. 353, pp. 368–70. https://doi.org/10.1126/science.aaf6524.

Y. Ogawa, D. Ando, Y. Sutou, H. Somekawa, and J. Koike: Shap. Mem. Superelast., 2018, vol. 4, pp. 167–73. https://doi.org/10.1007/s40830-017-0143-y.

K. Yamagishi, Y. Ogawa, D. Ando, Y. Sutou, and J. Koike: Scr. Mater., 2019, vol. 168, pp. 114–18. https://doi.org/10.1016/j.scriptamat.2019.04.023.

K. Yamagishi, D. Ando, Y. Sutou, and Y. Ogawa: Mater. Trans., 2020, vol. 61, pp. 2270–75. https://doi.org/10.2320/matertrans.MT-M2020244.

K. Yamagishi, Y. Ogawa, D. Ando, and Y. Sutou: J. Alloys Compd., 2023, vol. 931, p. 167507. https://doi.org/10.1016/j.jallcom.2022.167507.

K. Yamagishi, K. Onyam, Y. Ogawa, D. Ando, and Y. Sutou: J. Alloys Compd., 2023, vol. 938, 168415.

M. Haghshenas: J. Magn. Alloys, 2017, vol. 5, pp. 189–201. https://doi.org/10.1016/j.jma.2017.05.001.

D.P. Dunne and C.M. Wayman: Metall. Trans., 1973, vol. 4, pp. 137–45. https://doi.org/10.1007/BF02649612.

T. Maki, K. Kobayashi, M. Minato, and I. Tamura: Scr. Metall., 1984, vol. 18, pp. 1105–09. https://doi.org/10.1016/0036-9748(84)90187-X.

Y. Ogawa, Y. Sutou, D. Ando, J. Koike, and H. Somekawa: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 3044–47. https://doi.org/10.1007/s11661-019-05260-7.

T. Omori, T. Kusama, S. Kawata, I. Ohnuma, Y. Sutou, Y. Araki, K. Ishida, and R. Kainuma: Science, 2013, vol. 341, pp. 1500–02. https://doi.org/10.1126/science.1238017.

D. Ando, Y. Ogawa, T. Suzuki, Y. Sutou, and J. Koike: Mater. Lett., 2015, vol. 161, pp. 5–8. https://doi.org/10.1016/j.matlet.2015.06.057.

Y. Ogawa, D. Ando, Y. Sutou, and J. Koike: Mater. Trans., 2016, vol. 57, pp. 1119–23. https://doi.org/10.2320/matertrans.M2016093.

Y. Ogawa, Y. Sutou, D. Ando, and J. Koike: J. Alloys Compd., 2018, vol. 747, pp. 854–60. https://doi.org/10.1016/j.jallcom.2018.03.064.

J. Xia, T. Omori, and R. Kainuma: Scr. Mater., 2020, vol. 187, pp. 355–59. https://doi.org/10.1016/j.scriptamat.2020.06.044.

M. Vollmer, T. Arold, M.J. Kriegel, V. Klemm, S. Degener, J. Freudenberger, and T. Niendorf: Nat. Commun., 2019, vol. 10, p. 2337. https://doi.org/10.1038/s41467-019-10308-8.

T. Kusama, T. Omori, T. Saito, S. Kise, T. Tanaka, Y. Araki, and R. Kainuma: Nat. Commun., 2017, vol. 8, p. 354. https://doi.org/10.1038/s41467-017-00383-0.

T. Omori, H. Iwaizako, and R. Kainuma: Mater. Des., 2016, vol. 101, pp. 263–69. https://doi.org/10.1016/j.matdes.2016.04.011.

T. Odaira, X. Xu, A. Miyake, T. Omori, M. Tokunaga, and R. Kainuma: Scr. Mater., 2018, vol. 153, pp. 35–39. https://doi.org/10.1016/j.scriptamat.2018.04.033.

T. Odaira, S. Xu, X. Xu, T. Omori, and R. Kainuma: Appl. Phys. Rev., 2020, vol. 7, p. 031406. https://doi.org/10.1063/5.0007753.

K. Yamagishi, K. Onyam, Y. Ogawa, D. Ando, and Y. Sutou: J. Alloys Compd., 2023, vol. 938, p. 168415. https://doi.org/10.1016/j.jallcom.2022.168415.

Acknowledgments

This work was supported by JSPS KAKENHI [Grant Numbers 21J12146, 18H01691]; and the Adaptable and Seamless Technology transfer Program through Target-driven R&D (A-STEP) from Japan Science and Technology Agency (JST) [Grant Number JPMJTR20TJ].

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Abnormal Grain Growth Induced by Cyclic Heat Treatment

As referred in the original text, grain size of disordered bcc (A2) matrix phase can be enlarged through abnormal grain growth (AGG) induced by cyclic heat treatment (CHT).[20,28] In this study, two types of CHTs were used, as shown in Figures A1(a) and (b). In particular, cold rolled sheets were solution heat treated at 690 °C for 30 minutes, followed by air cooling to room temperature in a CHT, and the CHT was repeated several times. Subsequently, the CHTed samples were solution heat treated at 690 °C for 30 minutes, followed by water quenching to obtain an A2 single-phase. CHT was applied once (CHT-a) to the samples for differential scanning calorimeter (DSC) measurements, transmission electron microscope (TEM) observations, and tensile tests (polycrystalline samples), whereas CHT was repeated ten times (CHT-b) for tensile test (a bamboo-crystalline sample). Figures A1(c) and (d) show the obtained typical micrograph and photo after the CHT-a and CHT-b, respectively, in which grain boundaries are highlighted with black lines. Before observation, a sample’s surface was mechanically polished with SiC papers and diamond pastes with different grit, and chemically etched to obtain mirror-like surface.

Foregoing CHT-induced AGG was first reported by Omori et al.[28] and has been reported in various alloys.[20,28,32,33,34,35,36,37] The most possible mechanism is reported as follows: subgrain structure is introduced in a matrix phase through CHTs because of the precipitation and dissolution of second phases in the matrix phase, and the subgrain boundary energy works as an additional driving force for grain growth.[32,33,34,35] For Mg–Sc alloy, hcp phases precipitate and dissolve in the A2 matrix phase, which should produce subgrain structures and induce AGG[20,38] (Figures A2, A3).

Full view of in-situ DSC result, parts of which are shown in Figs. 1(a) and (b)

Full view of (a) in-situ DSC result and (b) DSC result measured after aging treatment at 100 °C for 720 min in silicone oil, parts of which are shown in Figs. 1(d) and (e)

1.2 Effect of Aging Treatment on Hardness

Vickers hardness tests were performed for hardness testing at room temperature, where the load was set to 1.0 kgf. The average hardness value was calculated from 10 points. Hardness change as a function of aging time at 100 °C are shown in Figure A4, indicating that aging treatment at 100 °C, or B2 ordering of matrix phase, does not considerably change hardness.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yamagishi, K., Takeuchi, Y., Ogawa, Y. et al. B2 Ordering and Its Effect on Room Temperature Superelasticity in Mg–Sc Alloy. Metall Mater Trans A 54, 2841–2848 (2023). https://doi.org/10.1007/s11661-023-07062-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07062-4