Abstract

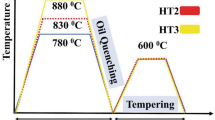

Hydrogen-induced cracking (HIC) occurs in pipeline steels used in oil and gas applications that are rich in hydrogen sulfide gas also known as sour service environments. In this study, an experimental X65 steel was produced by intercritically finish rolling, accelerated cooling, then air-cooling to room temperature. This thermo-mechanical processing scheme resulted in a mixture of quasi-polygonal ferrite and martensite/austenite (M/A) microconstituents, also known as granular bainite. Sections from the steel were also tempered at 300 °C, 400 °C, 500 °C, and 600 °C for 40 min, which resulted in a significant increase in HIC resistance and impact toughness, along with a marginal increase in yield strength and maintenance of untempered hardness. The evolution of HIC resistance, tensile properties, and impact toughness is discussed in the context of phase fraction, dislocation density, and microstructural evolution. The current work demonstrates the potential for tempering after thermo-mechanical processing to reduce HIC susceptibility and increase impact toughness while nominally maintaining yield strength and hardness in microalloyed pipeline steels.

Similar content being viewed by others

Change history

19 June 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11661-023-07102-z

References

Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production, NACE MR0175/ISO15156–2, 2019.

K.O. Findley, S.K. Lawrence, and M.K. O’Brien: Encyclopedia of Materials: Metals and Alloys, vol. 2, Elsevier Inc., Cambridge, MA, 2021, pp. 235–49.

Y. Zhou, T. Jia, X. Zhang, Z. Liu, and R.D.K. Misra: Mater. Sci. Eng. A, 2015, vol. 626, pp. 352–61.

G. Krauss: Steels- Processing Structure and Performance, 2nd ed. ASM International, Materials Park, OH, 2005.

B.C. De Cooman and J.G. Speer: Fundamentals of Steel Product Physical Metallurgy, Association for Iron & Steel Technology, Warrendale, PA, 2012, pp. 135–89.

G. Krauss: Iron Steel Technol., 2011, vol. 8, pp. 187–95.

V. Euser: PhD Thesis, Colorado School of Mines, 2020.

V.K. Judge: M.S. Thesis, Colorado School of Mines, 2017.

V.K. Judge, J.G. Speer, K.D. Clarke, K.O. Findley, and A.J. Clarke: Sci. Rep., 2018, vol. 8, pp. 1–6.

Y. Luo, J. Min Peng, H. Bin Wang, and X. Chun Wu: Mater Sci. Eng. A., 2010, vol. 527(15), pp. 3433–37.

I. Vieira: PhD Thesis, Colorado School of Mines, 2018.

I. Vieira, J. Klemm-Toole, E. Buchner, D.L. Williamson, K.O. Findley, and E. De Moor: Sci. Rep., 2017, vol. 7, pp. 1–4.

B.L. Bramfitt and J.G. Speer: Metall. Trans. A, 1990, vol. 21, pp. 817–29.

T. Tanaka: Int. Met. Rev., 1981, vol. 26, pp. 185–212.

W.K. Kim, S.U. Koh, B.Y. Yang, and K.Y. Kim: Corros. Sci., 2008, vol. 50, pp. 3336–42.

X.B. Shi, W. Yan, W. Wang, L.Y. Zhao, Y.Y. Shan, and K. Yang: Acta Metall. Sin. Eng. Lett., 2015, vol. 28, pp. 799–808.

G.T. Park, S.U. Koh, H.G. Jung, and K.Y. Kim: Corros. Sci., 2008, vol. 50, pp. 1865–71.

S.U. Koh, H.G. Jung, K.B. Kang, G.T. Park, and K.Y. Kim: Corrosion, 2008, vol. 64, pp. 574–85.

F. Boratto, R. Barbosa, S. Yue, J.J. Jonas: International Conference on Physical Metallurgy of Thermomechanical Processing of Steels and Other Metals, 1988, pp. 383–90.

M.K. O’Brien: PhD Thesis, Colorado School of Mines, 2021.

Standard Test Methods for Tension Testing of Metallic Materials, ASTM E8/E9M, 2008.

Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, ASTM E23, 2018.

Evaluation of Pipeline and Pressure Vessel Steels for Resistance to Hydrogen-Induced Cracking, NACE TM0284, 2016.

D.T. Pierce, D.R. Coughlin, D.L. Williamson, K.D. Clarke, A.J. Clarke, J.G. Speer, and E. De Moor: Acta Mater., 2015, vol. 90, pp. 417–30.

S. Takebayashl, T. Kunieda, N. Yoshinaga, K. Ushioda, and S. Ogata: ISIJ Int., 2010, vol. 50, pp. 875–82.

ImageJ, (n.d.). Image Processing and Analysis in Java. imagej.net/ij/.

P. Schaaf, S. Wiesen, and U. Gonser: Acta Metall. Mater., 1992, vol. 40, pp. 373–79.

D.T. Pierce, D.R. Coughlin, D.L. Williamson, J. Kähkönen, A.J. Clarke, K.D. Clarke, J.G. Speer, and E. De Moor: Scr. Mater., 2016, vol. 121, pp. 5–9.

M.S. Rashid and V.N. Rao: Metall. Trans. A, 1982, vol. 13, pp. 131679–86.

P.H. Chang: Metall. Trans. A, 1984, vol. 15, pp. 73–86.

M.W. Tong, P.K.C. Venkatsurya, W.H. Zhou, R.D.K. Misra, B. Guo, K.G. Zhang, and W. Fan: Mater. Sci. Eng. A, 2014, vol. 609, pp. 209–16.

H. Zhang, X. Cheng, B. Bai, and H. Fang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 920–24.

J. Nieto, T. Elias, G. Lopez, G. Campos, F. Lopez, R. Garcia, A.K. De: Mater. Sci. Tech. A, 2012, pp. 1044–53.

J. Nieto, T. Elías, G. Lopez, G. Campos, F. Lopez, R. Garcia, and A.K. De: J. Mater. Eng. Perform., 2013, vol. 22, pp. 2493–99.

K. Matsumoto, Y. Kobayashi, K. Ume, K. Murakami, K. Taira, and K. Arikata: Corrosion, 1986, vol. 42, pp. 337–45.

M.A. Mohtadi-Bonab, M. Eskandari, and J.A. Szpunar: Mater. Sci. Eng. A, 2014, vol. 620, pp. 97–106.

G. Angus: M.S. Thesis, Colorado School of Mines, 2014.

Acknowledgments

The support of the sponsors of the Advanced Steel Processing and Products Research Center, an industry-university cooperative research center at the Colorado School of Mines; and Arcelor Mittal, for providing the material.

Funding

This work was supported by the Advanced Steel Processing and Products Research Center at the Colorado School of Mines, Golden, CO.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

O’Brien, M.K., Lucon, E., Huey, Z. et al. Improved Resistance to Hydrogen-Induced Cracking by Tempering of Intercritically Rolled Accelerated-Cooled X65 Steel. Metall Mater Trans A 54, 2146–2159 (2023). https://doi.org/10.1007/s11661-023-06975-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-06975-4